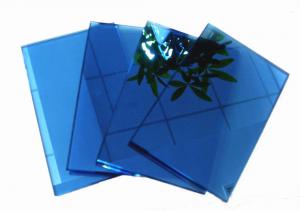

Tinted Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinted Glass, also called self colored glass, has possessed low UV transmittance and good shading effects, which are because of its abundant colors and good decorative effects.

Features:

1. Diversified Color Series

2. Excellent Product Quality

3.Consistency of color

4. Complete Specifications

5. Continuous aand Stable Supply

Specifications:

Thickness: 3-12mm

Size: 920*1016mm

3300*3660mm

customized size

Applications:

Tinted Glass is widely used in mirror-making, bathroom, furniture, building, automotive glass and etc.

- Q: What material is made of bullet proof glass?

- Bulletproof glass is made of glass (or organic glass) of a composite material and the quality of engineering plastics through special processing is obtained, it is usually transparent material, usually including polycarbonate layer on glass layer.

- Q: How is glass made? What are the main ingredients?

- Raw material pretreatment. The bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) are crushed to damp the raw materials, and the iron bearing raw material is treated with iron to ensure the quality of the glass.

- Q: Renovation of the house to buy bricks when how to see the quality of good or bad? What kind of good?

- Mosaic is mainly divided into glass mosaic (raw materials for glass) and ceramic mosaic two. Mainly used for decorative wall.

- Q: Long plastic soft glass is a food grade raw materials?

- No, this is the PVC material processing process, there will be plasticizers, etc., although non-toxic, harmless, but the food grade standards or worse.

- Q: Why is toughened glass broken?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: How can the vacuum tubes of solar water heaters be chromatic aberration? Is purple good or sky blue good?

- Fundamental difference: the structure of the film is different, resulting in the principle of absorbing solar rays is not the same. As a multilayer film, the absorption layer is usually 9 layers. It absorbs the solar rays by layer by layer, and absorbs the light gradually. As a result of this gradient structure, the emission ratio increases with the increase of temperature, so that when the working temperature is 300~500 degrees centigrade, the emissivity ratio increases greatly. Moreover, the aluminum ions in the absorption layer are greatly enhanced and shifted at high temperature. In this way, the internal structure of the film is disordered, leading to the aging of the film. At this high temperature for a long time, the film will fall off, thus affecting the heat collection efficiency and life of the vacuum tube.

- Q: What is glass fiber reinforced nylon?

- GFR-nylon adds a certain amount of nylon resin in glass fiber reinforced plastic (FR-PA) and can be divided into long glass fiber reinforced nylon coating prepared (fiber and plastic particles equal, generally about 10mm) and the short cut fiber after mixing, or continuous fiber guide short glass fiber into double screw extruder continuous shear mixing of reinforced nylon (glass fiber length of about 0.0.7mm. 2.) belongs to the nylon polyamide amine in its main chain. Amino is polar, due to the effects of hydrogen bonding and attract each other. So the nylon easy to crystallize, can be made into high strength fibers. Polyamide as translucent cuticle toughness or white crystalline resin, often made of cylindrical pellets for polyamide plastic with molecular weight ranging from 15 thousand to 20 thousand.

- Q: The main raw material for the impact of float glass cost?

- Process: mainly to see whether the enterprise has mastered the key technology of float process control. For example, master the melting technology, need to have stripe analysis equipment to monitor, can detect fault signs in advance, timely fine-tuning, can avoid major accidents, development. In the case of melting stability, general forming and annealing are relatively easy to achieve stability; the products produced by such a line are stable and the cost will be greatly reduced. But at present, the only part of enterprises to master the technology, many enterprises are repeatedly in fluctuation, a fluctuation of about 3-7 days, so the product quality can not guarantee long-term stability, there is no guarantee to do the processing of glass, benefits decline.

- Q: What are the characteristics of the gas flow in the flame space of a glass furnace?

- The main raw materials of flat glass are: silica sand (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite. Process: 1, raw material crushing: the raw materials are crushed into powder; 2, weighing: according to plan the list of ingredients said powder can take a certain amount of; 3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);

- Q: What are the main materials for making glass?

- Glass material mainly has three parts: basic material, flux and colorant, and also includes decoloring agent, clarifying agent and corrosion inhibitor* basic materials for glass making

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1984 |

| Annual Output Value | US$ 0.5 Million |

| Main Markets | Mid East; Eastern Europe; North America; Europe; Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese; Korean |

| b) Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Tinted Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords