Tinplate with prime quality hot sale products

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

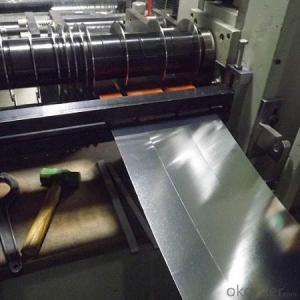

Tinplate with prime quality hot sale products

Product Description

- Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2. Main Features

Tinplate is widely used for making all type of containers, electrical machinery parts and many other products.

3 Pictures.

4. Applications

- Chemical and Painting Cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans

- Liquid food cans, such as edible oil cans, beverage cans, tomato paste cans

- Sea food cans

- Crown corks, easy open ends

- Electrical Machinery parts

- Bakeware and household kitchen parts

5.FAQ

CNBM is a state- owned enterprise, top 1 in China steel industry, top 500 world wide. Our tinplate annual capacity is 400,000metric tons. First class level with competitive price.

- Q: What are the different grades of tinplate?

- The different grades of tinplate include Single Reduced (SR), Double Reduced (DR), and Electrolytic Chromium Coated Steel (ECCS).

- Q: What are the safety regulations for tinplate packaging?

- The safety regulations for tinplate packaging vary depending on the specific product being packaged. However, in general, tinplate packaging must meet standards set by regulatory bodies such as the Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). These regulations typically cover aspects such as the use of safe materials, proper labeling, and ensuring the packaging does not contaminate the product. Additionally, tinplate packaging must often undergo testing for factors such as durability, resistance to corrosion, and overall safety during handling and transportation.

- Q: What are the advantages of tin packaging?

- Mature technology and high production efficiency: the production of tinplate has a long history, has a mature skill set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: How does tinplate contribute to the reduction of plastic waste?

- Tinplate contributes to the reduction of plastic waste by providing a sustainable alternative for packaging. Tinplate containers are durable, recyclable, and can be reused multiple times. This reduces the need for single-use plastic packaging, thereby minimizing the amount of plastic waste generated.

- Q: How does the tin coating affect the weldability of tinplate?

- The tin coating on tinplate actually improves the weldability of the material. It acts as a protective layer, preventing oxidation and minimizing the formation of impurities during the welding process. This results in a stronger and more reliable weld, making tinplate a preferred choice for various applications requiring good weldability.

- Q: What are the main factors affecting tinplate coil loading and unloading?

- The main factors affecting tinplate coil loading and unloading include the size and weight of the coils, the type and condition of the loading and unloading equipment, the skill and experience of the operators, and the safety precautions in place. Additionally, factors such as the layout of the loading and unloading area, weather conditions, and any specific requirements or regulations for handling tinplate coils may also impact the process.

- Q: How long does tinplate packaging last?

- Tinplate packaging can last for a long time, typically between 5 to 10 years, depending on various factors such as the storage conditions, handling, and maintenance.

- Q: How is tinplate cut and shaped for different packaging designs?

- Tinplate is typically cut and shaped for different packaging designs using specialized cutting and shaping tools, such as shears, dies, and molds. These tools allow manufacturers to cut the tinplate sheets into desired shapes and sizes, as well as bend, fold, and form them into various packaging designs. Additionally, stamping and embossing techniques may be employed to create intricate patterns and textures on the tinplate. Overall, the process involves a combination of precise cutting, shaping, and forming techniques to achieve the desired packaging design.

- Q: Does the tinplate have a tensile rate? Thank you heroes!

- Yes, what does it look like?. Deep drawing pot should be higher tensile rate (also known as elongation), the harder the material, the lower the tensile rate; the industry generally does not have a uniform tensile rate, generally in order to replace the cup burst value test.

- Q: What are the main factors influencing the supply of tinplate?

- The main factors influencing the supply of tinplate are the availability and cost of tin, the demand for tinplate products, the production capacity of tinplate manufacturers, and any trade barriers or regulations that may affect the import/export of tinplate.

Send your message to us

Tinplate with prime quality hot sale products

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords