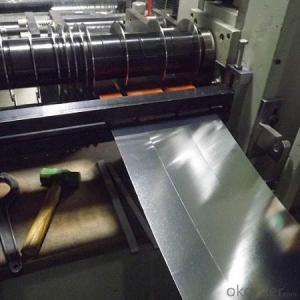

Tinplate with Prime Quality and Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate for Food Pakcaging and Chemical Packaging

Specifications

Prime electrical tinplate:

Thickness: 0.15 to 0.50mm

Width: 600 to 1010mm

Temper grade: BA and CA

For metal packaging usage

The Tinplate specification as following:

1, Reference standard: GB2520-88, JIS G3303-1997 and DIN EN10203-91

2, Material: MR, SPCC

3, Thickness available: 0.15mm to 0.50mm

4, Width available: 600mm to 1010 mm

5, Temper grade: T1 - T5 BA and CA both.

6, Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g, We also can produce according to customers' requests

7,Coil diameter: ID 420/ 508mm, OD from 1,000 to 1,250mm

8,Package: Anti-rust paper,corner protected. by sheet or coils according customer's require.

9, Applications: metal package usage like paint, chemical can,aerosol can and different food can production,

Also battery,electric cable and other industries

| Tinplate specifications | |||

| Steel Type | SPCC, MR | ||

| Temper(BA&CA) | T1~T5 | ||

| Coating | 1.1~11.2g/m2 | ||

| Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) | ||

| Width & tolerance | 300~1000mm (Tolerance: 0~3mm) | ||

| Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) | ||

| Coil inside diameter | 420/508mm | ||

| Coil Weight | 3~10 MT | ||

| Passivation | 311 | ||

| Oiling | DOS | ||

| Surface Finish | Bright, Stone, Silver, Matte | ||

| Packaging | Seaworthy Standard with wooden pallet | ||

| Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 | ||

| Special specitications are available on request. | |||

| Tin coating weight | |||

| Type | Designation of tin coating weight | Min.average tin coating weight(g/m2) | Former Coating Designation |

| Equal tin coating | 1.4/1.4 | 1.2/1.2 | #15 |

| 2.2/2.2 | 2.0/2.0 | #20 | |

| 2.8/2.8 | 2.45/2.45 | #25 | |

| 5.6/5.6 | 5.05/5.05 | #50 | |

| 8.4/8.4 | 7.55/7.55 | #75 | |

| 11.2/11.2 | 10.1/10.1 | #100 | |

| Differentially Coating | 1.4/2.8 | 1.2/2.45 | #15/25 |

| 2.2/2.8 | 2.2/2.45 | #20/25 | |

| 2.8/5.6 | 2.45/5.05 | #25/50 | |

| 2.8/8.4 | 2.45/7.55 | #25/75 | |

| 2.8/11.2 | 2.45/10.1 | #25/100 | |

| 5.6/8.4 | 5.05/7.55 | #50/75 | |

| 5.6/11.2 | 5.05/10.1 | #50/100 | |

| 8.4/11.2 | 7.55/10.1 | #75/100 | |

| Surface finish | |||

| Surface finish | Nominal surface roughness (um Ra) | Characteristic | |

| Bright finish | ≤Q0.35 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail strip with extremely fine rubstone fingure by processing. | |

| Stone finish | 0.25~0.60 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail stripfeaturing certain rubstone figures. | |

| Silver finish | 0.50~1.00 | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip with rough matt furface. | |

| Matte finish | 0.80~2.50 | Matt surface of general matt raw material strip without melting treatment. | |

- Q: How does tinplate compare to stainless steel in terms of properties and applications?

- Tinplate and stainless steel differ significantly in terms of properties and applications. Tinplate, made by coating thin steel sheets with a layer of tin, offers good corrosion resistance and malleability, making it suitable for applications like food and beverage packaging, cans, and aerosol containers. On the other hand, stainless steel, an alloy of steel with chromium and other elements, provides superior corrosion resistance, strength, and heat resistance. It finds extensive use in industries like construction, automotive, kitchenware, and medical equipment. While tinplate is more cost-effective and suitable for lightweight applications, stainless steel offers higher durability and versatility for various demanding applications.

- Q: How is tinplate coated with organic materials for specific applications?

- Tinplate is coated with organic materials for specific applications through a process known as lacquering. Lacquering involves applying a thin layer of organic material, such as a resin or polymer, onto the surface of the tinplate. This coating provides protection against corrosion, enhances the aesthetic appearance, and improves the adhesion of inks or paints for printing or labeling purposes. The organic coating can be applied through various methods like roll coating, spray coating, or electrostatic deposition, depending on the specific requirements of the application.

- Q: How does tinplate compare to other packaging materials in terms of weight?

- Tinplate is relatively lightweight compared to other packaging materials.

- Q: How does tinplate contribute to the protection of textile products?

- Tinplate contributes to the protection of textile products by providing a durable and corrosion-resistant packaging material. It acts as a barrier against moisture, oxygen, and light, preventing the deterioration of textile products during storage and transportation. Tinplate's protective properties help maintain the quality, color, and integrity of textiles, ensuring they reach consumers in optimal condition.

- Q: What are the typical lead times for tinplate tooling?

- The typical lead times for tinplate tooling can vary depending on various factors such as the complexity of the design, size of the tooling, and the workload of the manufacturer. However, in general, lead times for tinplate tooling can range from a few weeks to a couple of months. It is important to communicate with the manufacturer or supplier to get a more accurate estimate based on your specific requirements.

- Q: What are the advantages of using tinplate for gift packaging?

- One of the advantages of using tinplate for gift packaging is its durability. Tinplate is a strong material that can withstand impact and protect the contents of the gift. Additionally, tinplate is resistant to corrosion, ensuring that the packaging remains intact and attractive even over time. Another advantage is its versatility - tinplate can be easily customized and decorated, allowing for endless design possibilities. Furthermore, tinplate is recyclable, making it an environmentally friendly choice for gift packaging.

- Q: What are the advantages of using tinplate for signage?

- There are several advantages of using tinplate for signage. Firstly, tinplate is highly durable and resistant to corrosion, ensuring that the signage can withstand various weather conditions and maintain its quality over time. Additionally, tinplate is lightweight, making it easier to install and transport. It also offers excellent printability, allowing for vibrant and long-lasting graphics on the signage. Moreover, tinplate is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice. Overall, the advantages of using tinplate for signage include durability, corrosion resistance, lightweight nature, excellent printability, and sustainability.

- Q: What are the main markets for tinplate?

- The main markets for tinplate are primarily the packaging industry, especially for food and beverages, as well as the manufacturing of cans, containers, and aerosol cans. Additionally, tinplate is used in various industries such as automotive, construction, electronics, and pharmaceuticals for its corrosion-resistant properties.

- Q: How has tinplate evolved over the years?

- Tinplate has evolved significantly over the years, primarily due to advancements in technology and manufacturing processes. Originally, tinplate was made by coating iron or steel with a thin layer of tin to prevent corrosion. However, the process has evolved to include various coatings, such as organic, chrome, and polymer coatings, that offer improved protection and durability. Additionally, the production techniques have become more efficient, allowing for higher quality and faster manufacturing of tinplate products. Moreover, the application of tinplate has expanded beyond traditional uses in packaging to include automotive, construction, and electrical industries, further driving its evolution.

- Q: What are the common industry standards for tinplate?

- The common industry standards for tinplate include specifications for the tin coating weight, the base metal thickness, surface finish, and the adhesion of the tin coating. These standards ensure consistency and quality in the production of tinplate, allowing for its effective use in various industries such as packaging, automotive, and construction.

Send your message to us

Tinplate with Prime Quality and Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords