PRIME Good QUALITY Tinplate ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We have been producing tinplate material professionally and providing related service for decades years. Now we have been exporting our material to the world. Please kindly contact us to meet your needs for ETP materail.

Below is the specification we currently do:

1. Standard: GB/T 2520-2000, JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR, SPCC

3.Thickness: 0.18 to 0.50mm

4. Width: 260 to 980mm

5. Coil diameter: ID 420mm or 508mm

6. Temper grade: T2, T3 and T4

7. Tin coating: ordinary 2.8 or 2.8g and 5.6g or 5.6g, can produce according to customer's requests

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

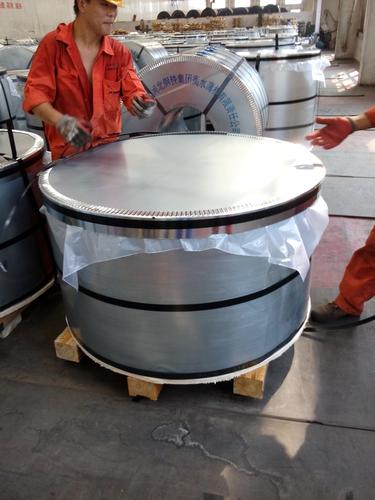

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's request.

Standard for Temper:

code | Chinese Stardard | Japaness Standard | American Standard | European Standard | International Standard |

| GB/T 2520-2000 | JIS G3303-2002 | ASTM A623M-2002 | DIN EN 10203-1991 | ISO 11949-1995 |

T-2 | TH52+SE | T-2 | T-2(53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 |

|

| TH55+SE |

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 |

|

|

|

|

|

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Surface of tinplate:

Marks | Surface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

- Q: How long does tinplate last?

- Tinplate can last for several decades if properly maintained and protected from corrosion.

- Q: How does tinplate handle exposure to light?

- Tinplate is not affected by exposure to light, as it is a durable material that does not undergo any chemical changes or degradation when exposed to light.

- Q: How does tinplate contribute to the overall tamper-evident packaging?

- Tinplate contributes to the overall tamper-evident packaging by providing a strong and durable material that can be easily sealed and remains intact when tampering is attempted. Its resistance to corrosion and tampering makes it an ideal choice for ensuring the security of packaged products.

- Q: What are the main applications of tinplate in the chemical industry?

- Tinplate is primarily used in the chemical industry for packaging purposes. It is commonly employed for the production of containers, cans, and drums used for storing various chemicals. Tinplate offers excellent corrosion resistance, ensuring the integrity and safety of the chemicals being stored. Additionally, its versatility allows for easy printing and customization of containers, making it a preferred choice for branding and labeling purposes in the chemical industry.

- Q: What are the disadvantages of using tinplate?

- Some disadvantages of using tinplate include its susceptibility to rust and corrosion, limited design options due to its rigid nature, higher cost compared to alternative materials, and potential health risks if the tin coating is damaged and ingested.

- Q: How is tinplate used in the cosmetics industry?

- Tinplate is commonly used in the cosmetics industry for packaging purposes. It is often utilized to make containers such as cans and tubes that store various cosmetic products like creams, lotions, and powders. Tinplate provides durability, protection, and a sleek appearance to these cosmetic packaging materials, ensuring the safety and preservation of the products.

- Q: What is the cost of tinplate?

- The cost of tinplate varies depending on factors such as the market demand, quantity purchased, and quality specifications. It is best to check with suppliers or market sources for the current pricing.

- Q: How does tinplate compare to plastic packaging in terms of sustainability?

- Tinplate generally has better sustainability credentials compared to plastic packaging. Tinplate is made from steel, which is a highly recyclable material, whereas plastic is derived from fossil fuels and has limited recycling capabilities. Tinplate can be recycled indefinitely without losing its qualities, while plastic recycling can be challenging due to different types of plastics and contamination issues. Additionally, tinplate packaging has a longer lifespan and offers better protection for products, reducing the need for excessive packaging. However, it is important to consider the overall life cycle impact, as both materials have environmental implications during production and transportation.

- Q: How is tinplate cut and shaped for different packaging designs?

- Tinplate is cut and shaped for different packaging designs using various techniques such as shearing, blanking, and deep drawing. Shearing involves cutting the tinplate into desired sizes using a sharp blade or scissors. Blanking is a process where the tinplate is cut into a specific shape, usually using a die and a press. Deep drawing involves stretching the tinplate over a die to create a three-dimensional shape, often used for cylindrical or curved packaging designs. These techniques allow for precise and customized shaping of tinplate to meet different packaging requirements.

- Q: How does tinplate contribute to the preservation of photographic equipment?

- Tinplate contributes to the preservation of photographic equipment by providing a durable and corrosion-resistant material for the construction of camera bodies and other components. This helps protect the sensitive internal mechanisms from external factors such as moisture, dust, and physical damage, thereby extending the lifespan of the equipment. Tinplate also helps maintain the overall aesthetic appeal of the equipment, as it can be easily coated or painted to enhance its appearance and protect it from scratches or wear.

Send your message to us

PRIME Good QUALITY Tinplate ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords