TINPLATE of Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

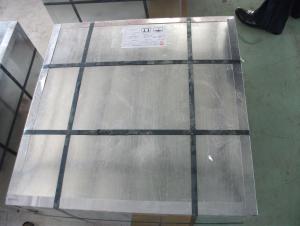

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: What are the regulations regarding tinplate packaging?

- Tinplate packaging is subject to various regulations, depending on the country and specific product being packaged. These regulations typically cover aspects such as food safety, labeling requirements, and environmental considerations. For example, in the United States, the Food and Drug Administration (FDA) regulates tinplate packaging for food products, ensuring they meet safety standards and are properly labeled. Additionally, there may be specific regulations related to recycling or disposal of tinplate packaging to minimize its impact on the environment. It is essential for businesses to research and comply with the relevant regulations to ensure their tinplate packaging meets all necessary requirements.

- Q: How does tinplate handle exposure to pressure and impact?

- Tinplate is known for its excellent strength and durability, making it capable of handling exposure to both pressure and impact effectively. It can withstand moderate levels of pressure without deformation or damage, and its rigid structure helps to absorb and distribute impact forces, minimizing the risk of denting or cracking. Overall, tinplate's resilience and robustness make it a reliable choice for applications where exposure to pressure and impact is expected.

- Q: Can tinplate be used for renewable energy applications?

- Yes, tinplate can be used for renewable energy applications. It is commonly used in the production of solar panels, wind turbines, and other renewable energy technologies. Tinplate's high strength and durability make it suitable for protecting and housing sensitive electronic components used in these applications. Additionally, tinplate's corrosion resistance ensures the longevity and performance of renewable energy systems, making it an ideal choice for such purposes.

- Q: How is tinplate priced?

- Tinplate is typically priced based on various factors such as market demand, raw material costs, production process, and quality standards. The pricing may also be influenced by market competition, regional variations, and global trade dynamics.

- Q: What are the main challenges in tinplate coil handling?

- The main challenges in tinplate coil handling include the risk of damage to the delicate tin coating, ensuring proper alignment and stacking to prevent coil deformation, and maintaining a safe working environment for operators due to the weight and size of the coils. Additionally, managing efficient storage and logistics to minimize handling and transportation costs is another significant challenge in tinplate coil handling.

- Q: How is tinplate manufactured?

- Tinplate is manufactured through a process called electroplating, where a thin layer of tin is applied onto a base metal, usually steel. The steel is first cleaned and then immersed into an electrolyte solution containing tin ions. An electric current is then passed through the solution, causing tin ions to be attracted and deposited onto the steel surface, forming a layer of tin. This tin coating provides the steel with corrosion resistance and enhances its appearance, making it suitable for various applications such as food and beverage packaging.

- Q: What are the common closure options for tinplate containers?

- Some common closure options for tinplate containers include screw caps, press-on lids, twist-off lids, and pull-tab lids.

- Q: How is tinplate used in the packaging industry?

- Tinplate is commonly used in the packaging industry due to its excellent properties such as corrosion resistance, durability, and formability. It is often used in the production of metal cans and containers for food and beverages, cosmetics, and other consumer goods. The tin coating on the steel substrate provides a protective barrier against moisture, light, and oxygen, ensuring the preservation and prolonging the shelf life of the packaged products. Tinplate is also used for decorative purposes, as it can be easily printed on, making it an ideal choice for branding and marketing.

- Q: What are the main applications of tinplate in the energy industry?

- Tinplate is commonly used in the energy industry for various applications such as the production of battery casings, electrical components, and packaging for energy storage devices. Its corrosion resistance, strength, and ability to withstand extreme temperatures make it a preferred material for these purposes. Additionally, tinplate's non-reactive nature ensures the integrity of energy storage systems, making it an ideal choice for the energy industry.

- Q: How big is the difference between tinplate and stainless steel 316L?

- 316L is a kind of austenitic stainless steel with excellent corrosion resistance. The tinplate is not comparable. 316L is superior to tinplate in appearance, corrosion resistance, heat resistance and strength. Of course, the price is much higher than that of tinplate.

Send your message to us

TINPLATE of Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords