TINPLATE OF Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

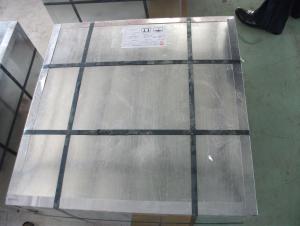

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: What are the main properties of tinplate?

- Tinplate is primarily known for its corrosion resistance, durability, and versatility. It is a thin steel sheet coated with a layer of tin, which provides a protective barrier against rust and oxidation. This makes tinplate suitable for packaging various food and beverage products. Additionally, its malleability allows for easy shaping and forming, making it ideal for intricate designs and embossing. Tinplate also exhibits excellent solderability, making it a preferred material for manufacturing cans, containers, and other metal products.

- Q: How does tinplate packaging contribute to product stability during transportation?

- Tinplate packaging contributes to product stability during transportation by providing a strong and durable barrier that protects the product from external factors such as moisture, light, and physical impact. Its rigid structure helps prevent deformation or crushing, ensuring the integrity of the product. Additionally, tinplate's excellent corrosion resistance properties safeguard against any potential damage caused by exposure to air or moisture. Overall, tinplate packaging plays a crucial role in maintaining the stability and quality of the product throughout the transportation process.

- Q: Can tinplate be reused after recycling?

- Yes, tinplate can be reused after recycling. Recycling tinplate involves melting it down to form new sheets of tinplate, which can then be used to manufacture various products such as cans, containers, and packaging materials. This process helps to conserve resources and reduce waste.

- Q: Tin and tinSince the back skin as long as tinplate will rust, so why not replace tin?

- Tin, also called galvanized sheet steel, atmospheric corrosion resistance ability is strong, not afraid of the rain and wind, used for building materials, general exposure in the air. Such as color plate, color steel. Because it is hard, so it is not easy to physical erosion. If the galvanized layer off, the same will rust.Can not be used. Instead of using tin tin galvanizing vessel, it is easy to cause zinc poisoning. Zinc soluble in acid, acid resistance is poor, so the tin can not be used for beverage packaging, such as carbonated drinks and fruit juice. In addition some foods, such as aquatic products, or products such as packaging, the requirements are higher, need to use advanced professional tinplate.

- Q: How is tinplate coated for household appliances?

- Tinplate is coated for household appliances through a process called electrolytic tinning. It involves immersing the steel sheet in an electrolyte bath while applying an electric current. This causes tin ions to be attracted to the steel sheet's surface, resulting in a smooth and corrosion-resistant coating.

- Q: What is tinplate?

- Tinplate is a type of steel that has been coated with a thin layer of tin. It is commonly used in the packaging industry to make cans for food and beverages. The tin coating provides protection against corrosion and improves the appearance of the steel.

- Q: What is the process for printing on tinplate?

- The process for printing on tinplate typically involves several steps. First, the tinplate sheets are cleaned and coated with a layer of primer to ensure proper adhesion of the ink. Then, the desired design or artwork is printed onto the tinplate using specialized printing techniques such as lithography or offset printing. After the printing is complete, the tinplate is usually coated with a protective varnish or lacquer to enhance its durability and resistance to corrosion. The printed tinplate sheets can then be further processed into various products, such as tin cans or decorative tin containers.

- Q: How does tinplate contribute to food safety?

- Tinplate contributes to food safety by providing a protective barrier between the food and the metal surface, preventing the transfer of any harmful substances or contaminants. Additionally, tinplate helps to preserve the quality and freshness of the food by preventing exposure to air, moisture, and light, which can lead to spoilage.

- Q: How does the printing process affect the durability of tinplate?

- The printing process can have both positive and negative effects on the durability of tinplate. On one hand, the application of a protective coating during the printing process can enhance the tinplate's resistance to corrosion, scratches, and other forms of damage. This can significantly improve its overall durability. On the other hand, if the printing process is not done properly or if low-quality inks or coatings are used, it can weaken the tinplate's protective layer, making it more prone to wear and tear. Therefore, the printing process plays a crucial role in determining the durability of tinplate.

- Q: What are the advantages of using tinplate for medical packaging?

- There are several advantages of using tinplate for medical packaging. Firstly, tinplate is highly durable and provides excellent protection to the packaged medical products. It is resistant to corrosion, ensuring the integrity and safety of the contents. Secondly, tinplate is lightweight yet sturdy, making it easy to handle and transport. This reduces shipping costs and prevents damage during transit. Additionally, tinplate is impermeable to moisture, oxygen, and light, providing a high level of product protection and extending the shelf life of medical supplies. Lastly, tinplate is recyclable and has a low environmental impact, making it a sustainable choice for medical packaging.

Send your message to us

TINPLATE OF Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords