Tinplate Making Beverage Cans for hot sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

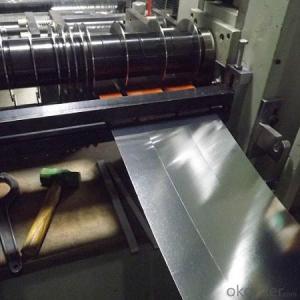

Tinplate with prime quality hot sale products

Product Description

- Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2. Main Features

Tinplate is widely used for making all type of containers, electrical machinery parts and many other products.

3 Pictures.

4. Applications

- Chemical and Painting Cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans

- Liquid food cans, such as edible oil cans, beverage cans, tomato paste cans

- Sea food cans

- Crown corks, easy open ends

- Electrical Machinery parts

- Bakeware and household kitchen parts

5.FAQ

CNBM is a state- owned enterprise, top 1 in China steel industry, top 500 world wide. Our tinplate annual capacity is 400,000metric tons. First class level with competitive price.

- Q: What are the common thicknesses of tinplate used for different applications?

- The common thicknesses of tinplate used for different applications can vary, but generally range from 0.13mm to 0.49mm. However, specific thickness requirements may depend on the intended use, such as packaging, electronics, or construction.

- Q: What are the main applications of tinplate in the paint industry?

- Tinplate is commonly used in the paint industry for the production of paint cans or containers. Its corrosion-resistant properties make it a suitable material for storing paint, ensuring that the paint remains fresh and uncontaminated. Additionally, tinplate cans are easy to seal, preventing any leakage or spillage of paint. Overall, the main application of tinplate in the paint industry is for the manufacturing of durable and reliable paint containers.

- Q: What are the different types of tinplate finishes available?

- There are several different types of tinplate finishes available, including bright finish, stone finish, matte finish, and lacquered finish. Each finish has its own unique appearance and characteristics, allowing for a variety of options when it comes to tinplate products.

- Q: How does tinplate handle exposure to extreme temperatures?

- Tinplate generally handles exposure to extreme temperatures quite well. It has a high melting point and can withstand high temperatures without deforming or losing its structural integrity. Additionally, tinplate has good thermal conductivity, allowing it to dissipate heat quickly. However, prolonged exposure to extremely high temperatures may cause some oxidation or discoloration on the tin coating. Overall, tinplate is a reliable material for various applications in extreme temperature conditions.

- Q: What is the global demand for tinplate?

- The global demand for tinplate is significant and steadily growing due to its versatile applications across various industries, such as packaging, automotive, construction, and electronics. Tinplate's corrosion resistance, durability, and aesthetic appeal make it a preferred choice for manufacturing cans, containers, and other packaging materials. Additionally, the increasing focus on sustainability and recyclability has further boosted the demand for tinplate as it is highly recyclable.

- Q: Can tinplate be used for aerosol cans?

- Yes, tinplate can be used for aerosol cans. Tinplate, which is steel coated with a thin layer of tin, is commonly used in the production of aerosol cans due to its strength, durability, and ability to resist corrosion.

- Q: How does tinplate contribute to the overall sustainability of the supply chain?

- Tinplate contributes to the overall sustainability of the supply chain in several ways. Firstly, it is a highly recyclable material, which means that it can be reused multiple times without compromising its quality. This reduces the need for virgin materials and minimizes waste generation. Secondly, tinplate has excellent barrier properties, protecting the contents of the packaging from external factors such as light, moisture, and oxygen, thus reducing food waste and extending shelf life. Additionally, tinplate is lightweight yet sturdy, enabling efficient transportation and reducing carbon emissions during shipping. Overall, tinplate's recyclability, protective properties, and transportation efficiency make it a sustainable choice in the supply chain.

- Q: Are there any limitations to using tinplate packaging?

- Yes, there are a few limitations to using tinplate packaging. Firstly, tinplate packaging is relatively heavy compared to other packaging materials, which can increase shipping costs and carbon footprint. Additionally, tinplate packaging is not suitable for certain products that require transparency or visibility, as it lacks transparency. Lastly, tinplate packaging may corrode if it comes in contact with acidic or alkaline substances, limiting its use for certain types of products.

- Q: What are the main challenges in tinplate storage and transportation?

- The main challenges in tinplate storage and transportation include ensuring proper handling to prevent damage or deformation, minimizing corrosion risks, managing space constraints efficiently, and maintaining temperature and humidity control to preserve the quality of the tinplate. Additionally, careful planning and coordination are necessary to ensure timely delivery and minimize bottlenecks in the supply chain.

- Q: Can tinplate be easily opened and resealed?

- No, tinplate cannot be easily opened and resealed as it typically requires specialized tools or equipment to open and seal it properly.

Send your message to us

Tinplate Making Beverage Cans for hot sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords