Tinplate in SPCC/ MR Grade With Printing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products: Tinplate

Tinplate and TFS are widely used for making all types of containers such as artistic cans, tea cans, painting cans, chemical package cans and metal printing etc. Its applications are not limited to containers; recently, they have also been used for making electrical machinery parts and many other products.

2. Specification:

Our goods enjoyed high quality both at home and abroad. We can supply tin free steel as follows:

Technical standard | JISG3303 and GB/T 2520-2008 |

Steel Type | MR / SPCC |

Thickness | From 0.15mm to 0.50mm (Tolerance +/- 0.01mm) |

Width | Normally 600-1050mm (Tolerance +3/-0 mm) |

Coating | 2.8/2.8g/m2 , 2.8/5.6g/m2 ,1.1/1.1 g/m2 |

Temper & Annealing | T1-T5, DR7-8, TS230-TH435, T49-T65(+/- 4) |

Surface Treatment | Bright & Fine Stone & Stone & Silver & Matt |

Payment terms | Letter of Credit (L/C), Telegraphic transfer (T/T) |

Price terms | CFR & CIF price term |

Delivery time | Within 60 days after received L/C or T/T down payment |

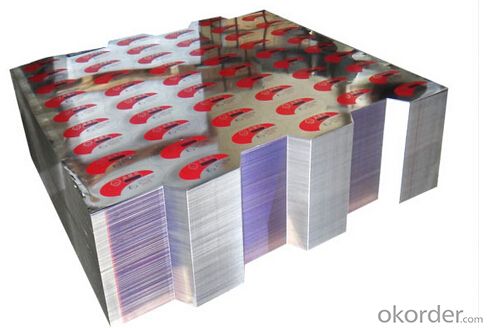

Packing | High quality shipping packing which contains thin plastic film, rust-proof paper, metal cover, metal angles and strap sand pallet. |

Minimum order Quantity(MOQ) | 25 metric tons (1X 20'' container) |

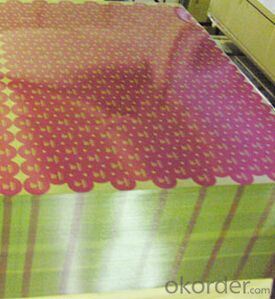

3. Pictures:

4. Features of the factory price/ tin free steel/tinplate/tfs/tmbp/etp/spte:

Beautiful Appearance

Excellent Paintability & Printability

Excellent Formability & Strength

Excellent Corrosion Resistance

Excellent Solderability & Weldability

5. FAQ:

We are one of the main producers in China for tinplate, tin free steel and also TMBP. At present, our productivity is more than 450000 MT/year.

For more information about our products or company, pls contact us freely.

Welcome your enquiries and orders.

- Q: What are the challenges in manufacturing tinplate?

- Some of the challenges in manufacturing tinplate include ensuring consistent coating thickness, preventing surface defects such as scratches or dents, controlling the tinplate's flatness and shape, and managing the overall production costs. Additionally, maintaining a clean and stable production environment, optimizing the manufacturing process to meet customer demands, and adhering to quality standards are also significant challenges in tinplate manufacturing.

- Q: How does tinplate contribute to the freshness of pet food?

- Tinplate, commonly used for pet food packaging, helps contribute to the freshness of pet food by providing a protective barrier against oxygen, light, and moisture. This prevents oxidation and spoilage of the food, preserving its quality and flavor for a longer period. Additionally, tinplate cans are hermetically sealed, preventing any external contaminants from entering the packaging, further enhancing the freshness and safety of the pet food.

- Q: What are the main applications of tinplate in the telecommunications industry?

- Tinplate has several main applications in the telecommunications industry, including the production of high-frequency cables and connectors, as well as the shielding of electronic components. Due to its excellent conductivity and corrosion resistance, tinplate is widely used in telecommunications infrastructure to ensure reliable signal transmission and protect sensitive equipment from electromagnetic interference.

- Q: How is tinplate coated to prevent corrosion?

- Tinplate is coated with a thin layer of tin to prevent corrosion.

- Q: How does tinplate packaging contribute to product convenience for consumers?

- Tinplate packaging contributes to product convenience for consumers in several ways. Firstly, tinplate packaging is lightweight and easy to handle, making it convenient for consumers to carry and transport the product. Secondly, tinplate packaging is durable and provides excellent protection for the product, ensuring that it remains intact and safe during transportation and storage. Additionally, tinplate packaging is airtight, keeping the product fresh and extending its shelf life, which is beneficial for consumers. Finally, tinplate packaging often comes with easy-to-open features like pull tabs or twist caps, making it convenient for consumers to access the product without the need for additional tools.

- Q: What are the main competitors of tinplate in the packaging industry?

- The main competitors of tinplate in the packaging industry are aluminum, glass, and various types of plastics such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP).

- Q: How is tinplate coated for cosmetic packaging?

- Tinplate is typically coated for cosmetic packaging using a process known as electrolytic tin coating. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it, causing a layer of tin to form on the surface of the tinplate. This tin coating provides a protective barrier against corrosion and enhances the aesthetic appearance of the packaging.

- Q: How is tinplate coated for chemical storage containers?

- Tinplate is typically coated for chemical storage containers using a process called electrolytic tin plating, where a layer of tin is electrochemically deposited onto the surface of the steel substrate. This tin coating helps to protect the container from corrosion and chemical reactions, ensuring safe storage and transportation of chemicals.

- Q: What are the different methods of sealing tinplate containers?

- There are several methods of sealing tinplate containers, including double seaming, soldering, welding, and using adhesive or pressure-sensitive seals. Each method offers its own advantages and is chosen based on factors such as the contents of the container, desired level of seal integrity, and production requirements.

- Q: Can tinplate be embossed or engraved?

- Yes, tinplate can be embossed or engraved.

Send your message to us

Tinplate in SPCC/ MR Grade With Printing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords