Tinplate For Metal Cans Uasge,Prime Grade/Secondary Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 40000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

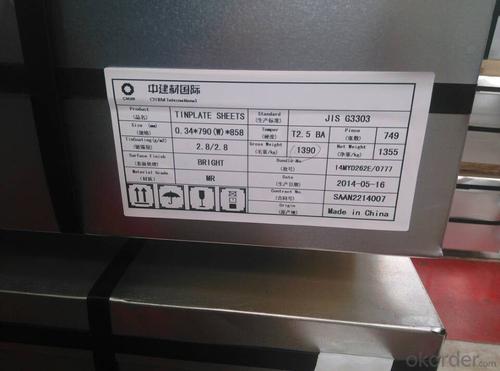

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

4. Our factory photo & equipments

5. Our CA Production Range

Temper | Thickness(mm) | Width(mm) | Length(mm) |

T3CA | 0.19~0.20 | 800~900 | 520~1068 |

0.21~0.25 | 800~950 | ||

0.26~0.45 | 800~1050 | ||

T4CA | 0.17~0.20 | 800~950 | |

0.20~0.45 | 800~1050 | ||

T5CA | 0.17~0.20 | 800~950 | |

0.20~0.28 | 800~1050 |

6. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: What are the main applications of tinplate in the telecommunications industry?

- Tinplate is commonly used in the telecommunications industry for the manufacturing of various components such as antennas, connectors, and shielding materials. Its corrosion-resistant properties make it ideal for ensuring optimal signal transmission and durability in these applications. Additionally, tinplate's ability to provide electromagnetic interference (EMI) shielding helps to prevent signal distortion and maintain the integrity of telecommunications systems.

- Q: Who knows the process of tinplate production?

- The basic production process of tinplate: pickling cold rolling cut I skim -- > I I I I I of Kaiping tin flat temperingTropical pickling: hot rolled coils must be pickled before cold rolling to produce cold rolling

- Q: How long does tinplate last?

- Tinplate can last for several decades if properly maintained and protected from corrosion.

- Q: Tin plated tin plated?

- Can electroplate.If the parts need tin plating, it is better not to use tinplate (tin plated steel / strip), galvanized steel plate / ordinary steel plate / strip with or without plating.

- Q: How does tinplate packaging contribute to product protection against light?

- Tinplate packaging contributes to product protection against light by providing a highly effective barrier that prevents light from reaching the product. The tin coating on the steel substrate acts as a reflective layer, reducing the amount of light transmission. This helps to shield the product from harmful UV radiation and other forms of light that can cause degradation, discoloration, or spoilage. Additionally, tinplate packaging can be further enhanced with additional protective coatings or lacquers that provide an additional layer of defense against light exposure, ensuring the product remains intact and protected.

- Q: How does tinplate compare to plastic-coated steel in terms of properties and applications?

- Tinplate and plastic-coated steel have different properties and applications. Tinplate is a thin, lightweight steel sheet coated with a layer of tin, which provides excellent corrosion resistance, solderability, and aesthetic appeal. It is commonly used in food and beverage packaging, as well as in the manufacturing of aerosol containers, electronic components, and various consumer products. On the other hand, plastic-coated steel is steel that is coated with a layer of plastic, typically through a process called extrusion. This coating enhances the steel's durability, impact resistance, and chemical resistance, making it suitable for applications that require protection against harsh environments or harsh handling. Plastic-coated steel is often used in construction, automotive, and electrical industries, where strength and corrosion resistance are crucial. In summary, tinplate is preferred for applications that require corrosion resistance, solderability, and a visually appealing finish, such as food packaging. Plastic-coated steel, on the other hand, is more suitable for applications that demand enhanced durability, impact resistance, and chemical resistance, like in construction or automotive industries.

- Q: What are the different types of tinplate finishes?

- There are several different types of tinplate finishes, including bright finish, stone finish, matte finish, and lacquered finish.

- Q: What are the main factors influencing the pricing of tinplate?

- The main factors influencing the pricing of tinplate include the cost of raw materials, such as tin and steel, which can fluctuate due to supply and demand dynamics. Other factors include production and manufacturing costs, including energy and labor expenses, as well as market competition and global economic conditions. Additionally, trade policies, tariffs, and regulations can also impact tinplate pricing.

- Q: What are the main applications of tinplate in the household goods industry?

- Tinplate is mainly used in the household goods industry for packaging food and beverages, such as canned goods, coffee, tea, and powdered milk. It provides a protective barrier against moisture, air, and light, ensuring the quality and freshness of the products. Additionally, tinplate is also used for making various household items like kitchen utensils, storage containers, and decorative items due to its durability and corrosion resistance properties.

- Q: Can tinplate be used for petrochemical packaging?

- Yes, tinplate can be used for petrochemical packaging. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent resistance against corrosion. This makes it suitable for packaging materials that come into contact with petrochemical products, as it helps protect the contents from degradation and contamination. Additionally, tinplate is also known for its durability and ability to withstand high temperatures, making it a reliable choice for petrochemical packaging.

Send your message to us

Tinplate For Metal Cans Uasge,Prime Grade/Secondary Grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 40000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords