Prime Grade Tinplate For Metal Cans Uasge

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

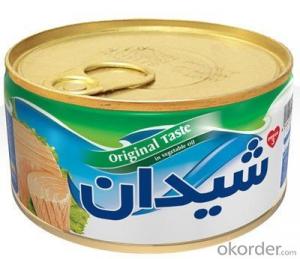

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

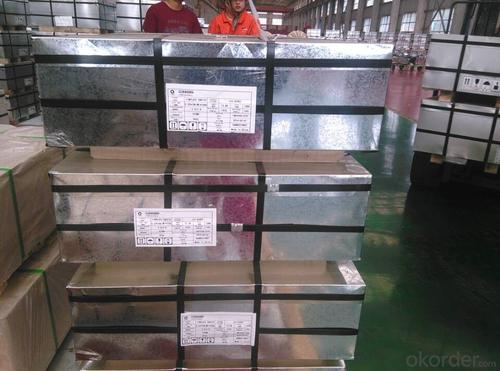

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: How does tinplate perform in terms of gas barrier properties?

- Tinplate exhibits excellent gas barrier properties, making it an effective material for packaging perishable goods and preventing the ingress of oxygen, moisture, and other gases.

- Q: How is tinplate coated with metallic coatings?

- Tinplate is coated with metallic coatings through a process called electroplating, where a layer of metal is deposited onto the tinplate surface using an electrolytic bath. This bath contains ions of the desired coating metal, which are attracted to the tinplate and form a thin and uniform layer through the application of an electric current. This electroplating process helps to enhance the durability, corrosion resistance, and aesthetic appearance of the tinplate.

- Q: How can tinplate be customized for branding purposes?

- Tinplate can be customized for branding purposes through various methods such as printing the brand logo and design on the surface of the tinplate, using different colors and finishes to enhance the visual appeal, embossing or debossing the brand name or slogan on the tinplate, and even incorporating unique shapes or patterns that represent the brand identity. These customization techniques help in creating a distinctive packaging solution that effectively promotes the brand and attracts customer attention.

- Q: What are the main challenges in tinplate coil handling?

- The main challenges in tinplate coil handling include the risk of damage to the delicate tin coating, ensuring proper alignment and stacking to prevent coil deformation, and maintaining a safe working environment for operators due to the weight and size of the coils. Additionally, managing efficient storage and logistics to minimize handling and transportation costs is another significant challenge in tinplate coil handling.

- Q: Can tinplate be used for chemical storage containers?

- Yes, tinplate can be used for chemical storage containers. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent corrosion resistance. This makes it suitable for storing various chemicals as it helps to prevent chemical reactions and preserve the integrity of the container.

- Q: What are the main growth drivers for the tinplate industry?

- The main growth drivers for the tinplate industry include increasing demand from the packaging sector, particularly for food and beverages, as tinplate offers excellent preservation properties. Additionally, the growing popularity of eco-friendly packaging solutions and the rise in disposable income in emerging economies are contributing to the industry's expansion. Furthermore, advancements in manufacturing technologies and the development of innovative tinplate products are driving the growth of the industry.

- Q: How is tinplate used in the manufacturing of kitchenware?

- Tinplate is commonly used in the manufacturing of kitchenware due to its unique properties. It provides a protective coating that prevents corrosion and enhances the durability of the kitchenware items. Tinplate is often used to create food cans, utensils, and other cookware. Its ability to resist corrosion and maintain food quality makes it a popular choice for kitchenware manufacturers.

- Q: Can tinplate be used for non-food products?

- Yes, tinplate can be used for non-food products. Tinplate is a versatile material that can be used in various industries such as automotive, construction, electronics, and packaging. Its corrosion resistance and durability make it suitable for non-food applications like metal cans, aerosol containers, electrical enclosures, and decorative items.

- Q: What are the main challenges in tinplate labeling?

- The main challenges in tinplate labeling include ensuring the label adheres well to the curved surface of the tinplate, maintaining label durability and resistance to moisture and other external factors, achieving accurate and consistent placement of the label, and ensuring the label does not peel or bubble over time.

- Q: Can tinplate be used for microwave-safe packaging?

- No, tinplate cannot be used for microwave-safe packaging as it is made of steel coated with a thin layer of tin, which can cause sparks and potential damage to the microwave.

Send your message to us

Prime Grade Tinplate For Metal Cans Uasge

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords