Tinplate for Food Cans Use With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate for Food Cans Use With High Quality

1.Structure of Description

Tinplate for Food Cans Use With High Quality is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

Price competitive

Good payment term

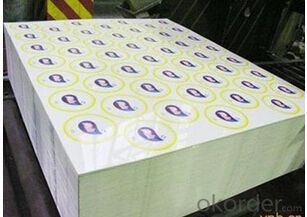

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC,MR

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5,DR8

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: How does tinplate packaging handle exposure to moisture?

- Tinplate packaging is highly resistant to moisture as it is coated with tin, which creates a barrier and prevents the metal from coming into contact with water. This protective layer ensures that the packaging remains intact and prevents any corrosion or damage from moisture exposure.

- Q: How does tinplate perform in terms of chemical resistance?

- Tinplate performs well in terms of chemical resistance due to its tin coating, which acts as a barrier against corrosion and chemical reactions. This coating provides excellent protection against acidic substances and prevents the metal from being affected by certain chemicals, making tinplate a reliable choice for packaging materials in various industries.

- Q: Can tinplate packaging be used for personal care products?

- Yes, tinplate packaging can be used for personal care products. Tinplate is a suitable material choice for packaging personal care products such as lotions, creams, and cosmetics due to its durability, resistance to corrosion, and ability to protect the contents from external factors such as light and moisture. Additionally, tinplate packaging can be easily customized and decorated to enhance the product's appeal.

- Q: What are the advancements in tinplate technology?

- Some of the advancements in tinplate technology include improved coatings for enhanced corrosion resistance, the development of thinner and lighter tinplate materials, and the introduction of advanced printing techniques for more vibrant and detailed designs. Additionally, there have been advancements in tinplate manufacturing processes, such as continuous annealing and tin-free steel alternatives, which have improved production efficiency and reduced environmental impact.

- Q: Can tinplate be used for furniture applications?

- Yes, tinplate can be used for furniture applications. It is a versatile material that offers durability and resistance to corrosion, making it suitable for various furniture components such as frames, panels, or decorative elements. Tinplate's malleability allows for intricate designs, while its smooth surface can be easily painted or coated to match any desired aesthetic.

- Q: Can tinplate be used for chemical storage containers?

- Yes, tinplate can be used for chemical storage containers. Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and protection against chemical reactions. This makes it suitable for storing various chemicals safely.

- Q: Is to buy canned tinplate or aluminum

- Buy tinplate, aluminum toxic, not good

- Q: Why tin printing after a layer of light oil

- The performance of tin light oil to complete all printing tin printing, to cover a layer of light oil, to increase the printing surface gloss and anti scratch performance, but also increase a certain hardness, the printing surface coating has certain flexibility and corrosion resistance.

- Q: Can tinplate be used for decorative purposes?

- Yes, tinplate can be used for decorative purposes as it provides a versatile and aesthetically pleasing material for various applications such as packaging, signage, and art. Its shiny surface and ability to be easily shaped and printed on make it a popular choice for creating visually appealing decorative items.

- Q: How is tinplate coated on both sides?

- Tinplate is coated on both sides by immersing the steel sheet in a bath of molten tin. This process, known as hot-dipping, ensures that both sides of the steel sheet are evenly coated with a layer of tin, providing protection against corrosion and enhancing its appearance.

Send your message to us

Tinplate for Food Cans Use With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords