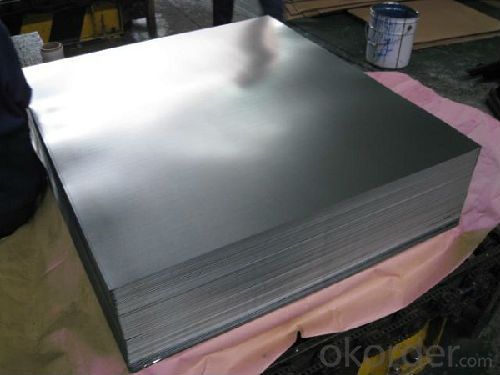

Prime Tinplate For All Kinds Of Food Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Quality Tinplate Sheets Details:

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

| | | | | | |

| | | | | |

Product Description:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

CNBM Introduction

China National Building Materials Group Cooperation, as a leading state-owned enterprise with 3 billion USD and 40,000 staff in China, CNBM was established in 1984 under the administration of the state-owned Assets Supervision and Administration commission of the State Council. There are over 300 surbordinate factories and companies in our group; 2 public listed companies in Hong Kong, 4 Public listed companies in China mainland; 11 publicly listed companies in which CNBM has a substantial percentage of shares. The business scope of CNBM covers from Manufacturing and sales of building materials to scientific research and design, engineering, import and export trading.

On July 7th, 2011, Fortune Magazine established Fortune Global 500 ranking on its website, and CNBM Group was listed for the first time, with a ranking of 485.

CNBM International Corporation

CNBM International Corporation, as an important import and export platform of CNBM Group, enjoys competitive advantages in importing and exporting of building materials as well as complete sets of machinery and equipments, engineering, and project contracting.

CNBM Branch Offices

In order to promote the business connection, CNBM has established branches and offices in lots of foreign countries, such as USA, GERMANY, UAE, SAUDI ARABIA, IRAN, JORDAN, LIBIA,ETHIOPIA, INDONESA, INDIA,VIETNAM,RUSSIA,KAZAKHSTAN. It is very helpful for the communication and after- sale services.

Factory Introduction

CNBM as one of the largest suppliers in tinplate industry, offers clientss prime quality tinplate in both coil and sheets. With multi-plants and fully integraded production, the annual capacity of tinplate is 400,000MT.

To ensure the high quality if the tinplate, CNBM owns complete equipment series.

- Reversing cold rolling machines: 14 sets

- Continuous rolling machines: 2 sets

- BA furnaces: 50

- CA line: 1

- Tinplate production line: 2

- SA& DA reduced tinplate sheet: Available

CNBM also produce other steel products, such as cold-rolled steel, hot dip galvanized steel, color coated steel and tin free steel coils and sheets.

- Q: How does tinplate contribute to the overall protection of packaged products?

- Tinplate contributes to the overall protection of packaged products by providing a strong and durable barrier against external elements such as moisture, light, and air. It helps to prevent corrosion, contamination, and spoilage, thereby extending the shelf life of the packaged products. Additionally, tinplate's resistance to impact and tampering ensures the integrity of the package, safeguarding the contents during transportation and handling.

- Q: What are the typical dimensions of tinplate sheets?

- The typical dimensions of tinplate sheets can vary, but they are commonly available in sizes ranging from 0.15mm to 0.35mm in thickness, with widths of 600mm to 1200mm, and lengths ranging from 800mm to 2400mm.

- Q: What are the advantages of using tinplate for pharmaceutical packaging?

- There are several advantages of using tinplate for pharmaceutical packaging. Firstly, tinplate is highly resistant to corrosion, ensuring that the integrity of the pharmaceutical product is maintained throughout its shelf life. Secondly, tinplate provides excellent barrier properties against moisture, oxygen, and light, protecting the medication from degradation. Additionally, tinplate is a strong and durable material, providing excellent protection during transportation and handling. Lastly, tinplate is recyclable, making it an environmentally friendly choice for pharmaceutical packaging.

- Q: How does tinplate contribute to the preservation of historical artifacts?

- Tinplate contributes to the preservation of historical artifacts by providing a protective coating that helps prevent corrosion and deterioration. The thin layer of tin on the surface of tinplate acts as a barrier, shielding the artifacts from exposure to air, moisture, and other harmful elements that can accelerate the degradation process. This preservation technique helps extend the lifespan of historical artifacts, ensuring they can be enjoyed and studied by future generations.

- Q: What are the different types of tinplate welding techniques?

- There are several types of tinplate welding techniques, including spot welding, seam welding, and projection welding.

- Q: What are the main export markets for tinplate?

- The main export markets for tinplate include countries such as China, Japan, the United States, Germany, and South Korea.

- Q: What are the main challenges in tinplate storage and transportation?

- The main challenges in tinplate storage and transportation include ensuring proper handling to prevent damage or deformation, minimizing corrosion risks, managing space constraints efficiently, and maintaining temperature and humidity control to preserve the quality of the tinplate. Additionally, careful planning and coordination are necessary to ensure timely delivery and minimize bottlenecks in the supply chain.

- Q: Can tinplate be used for signage and displays?

- Yes, tinplate can certainly be used for signage and displays. Tinplate is a versatile material that offers durability, strength, and a smooth surface for printing or painting. It can be easily shaped, cut, and formed to create various signage and display options, making it a popular choice for indoor and outdoor applications. Additionally, tinplate is resistant to corrosion, making it suitable for long-lasting and weather-resistant signage and displays.

- Q: Can tinplate be used as a water tower? Is hot water durable?

- Tinplate is commonly known as tin plated thin steel plate. It is a cold-rolled low carbon steel sheet or strip coated with pure tin on both sides. Tin plays a major role in preventing corrosion and rusting.

- Q: How is tinplate coated on both sides?

- Tinplate is coated on both sides through a process called electrolytic tinning. In this process, the tinplate is immersed in an electrolyte solution while an electric current is passed through it. This causes tin ions to be deposited on both sides of the tinplate, resulting in a thin layer of tin coating.

Send your message to us

Prime Tinplate For All Kinds Of Food Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords