Tin Free Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

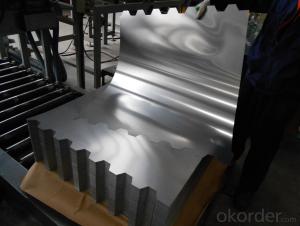

Tin Free Steel (TFS)

Is also known as chromed steel, as it is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.This steel product was developed to meet economic requirements, and excels tinplate in paintability, paint adhesion, and economy. It is widely used for making beverage cans and 18-liter cans. It is also used for making photographic film cases and as a protective material for optical fiber cables.

Our TFS Specification:

Standard: AISI, ASTM, BS, DIN, GB, JIS

Material: MR,SPCC

Thickness:0.15mm - 0.45mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

- Q: How does tinplate withstand corrosion?

- Tinplate withstands corrosion due to the presence of a thin layer of tin coating on its surface. This tin layer acts as a barrier, preventing direct contact between the tinplate and the surrounding environment, thus protecting it from rust and corrosion.

- Q: How does tinplate perform in terms of chemical resistance?

- Tinplate exhibits excellent chemical resistance, making it highly suitable for various applications. Its protective tin coating acts as a barrier, preventing direct contact between the metal and chemicals. This resistance ensures that tinplate remains unaffected by most corrosive substances, enhancing its durability and longevity.

- Q: How can tinplate be rustproof? Products must not be oil

- It has good salt spray resistance, drainage performance and resistance to hand sweating. It has a long time of rust prevention.

- Q: What are the different types of tinplate finishes available?

- Some of the different types of tinplate finishes available include bright, matte, and stone finishes.

- Q: What are the main challenges in tinplate coil handling?

- The main challenges in tinplate coil handling include ensuring proper lifting and transportation techniques to avoid damage, managing the weight and size of the coils for safe handling, maintaining cleanliness to prevent contamination, and implementing efficient storage and inventory management systems. Additionally, coordinating with suppliers and customers to ensure timely delivery and minimizing transit damage are also significant challenges.

- Q: How does tinplate affect the overall product shelf appeal?

- Tinplate enhances the overall product shelf appeal by providing a visually appealing and premium packaging solution. Its shiny and reflective surface adds a touch of sophistication and attractiveness, catching the attention of consumers. Additionally, tinplate's durability and strength protect the product, ensuring it remains intact and visually appealing throughout its shelf life.

- Q: What are the advantages of using tinplate for shipping containers?

- There are several advantages of using tinplate for shipping containers. Firstly, tinplate is highly durable and provides excellent protection against corrosion and oxidation, ensuring the contents of the container remain safe during transit. Secondly, tinplate is lightweight yet strong, allowing for easier handling and reducing transportation costs. Additionally, tinplate is easily recyclable, making it a sustainable choice for shipping containers. Lastly, tinplate offers a smooth surface which is conducive to branding and can be easily customized with logos and designs, enhancing the overall aesthetic appeal of the container.

- Q: What are the main challenges in tinplate labeling?

- The main challenges in tinplate labeling include ensuring proper adhesion of labels to the smooth and sometimes oily surface of tinplate, maintaining label integrity during the packaging and transportation process, and finding solutions to prevent label damage due to moisture, heat, or other environmental factors. Additionally, accurately positioning and aligning labels on curved or irregularly shaped tinplate surfaces poses a significant challenge.

- Q: How does the coating affect the properties of tinplate?

- The coating on tinplate significantly affects its properties. The coating provides a protective barrier against corrosion, enhancing the tinplate's durability and extending its shelf life. Additionally, the coating can improve the tinplate's resistance to chemical reactions and make it more suitable for food packaging applications. The coating also influences the tinplate's appearance, allowing for various decorative finishes. Overall, the coating plays a crucial role in enhancing the properties and performance of tinplate.

- Q: How does tinplate affect the overall weight of packaging?

- Tinplate tends to increase the overall weight of packaging due to its heavier density compared to other materials commonly used for packaging.

Send your message to us

Tin Free Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords