TIN FREE STEEL FOR MAKING CROWN CORK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

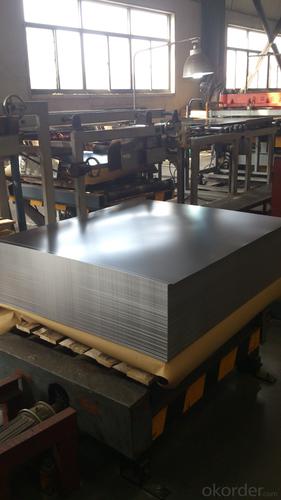

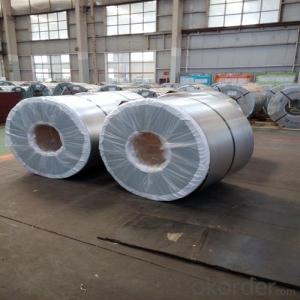

We are professionally supply Tin Free Steel and Tin Free Steel Sheet in China.

The Tinplate specification as following:

1.Reference standard:GB/T24180-2009;JIS G3315-2008

2.Material:SPCC/MR

3.Thickness avaiable:0.15mm to 0.36mm

4.Width available:600mm to 1050mm

5.Temper grade:T2-T5/DR8 BA and CA both

6.Coil weight:3-10T

7.Sheet weight:1-3T

8.Chrome coating weight:70-150mg/㎡

9.Package:Anti-rust paper,corner protected,by sheet or coils according customer's require.

- Q: What are the main applications of tinplate in the pharmaceutical industry?

- Tinplate is primarily used in the pharmaceutical industry for packaging purposes. Its main applications include the production of tinplate cans, containers, and closures. These tinplate packaging solutions provide a reliable and durable barrier against moisture, light, and oxygen, ensuring the protection and preservation of pharmaceutical products. Additionally, tinplate is also used for labeling and promotional purposes due to its excellent printability and aesthetic appeal.

- Q: Is tinplate resistant to scratches and dents?

- Yes, tinplate is resistant to scratches and dents.

- Q: Can tinplate packaging be used for clothing accessories?

- Yes, tinplate packaging can be used for clothing accessories. It is a durable and versatile material that can be shaped into various forms, making it suitable for packaging small items like jewelry, belts, or hair accessories. Additionally, tinplate packaging offers a unique and visually appealing option for displaying and protecting clothing accessories.

- Q: What are the advantages of using tinplate for shipping containers?

- There are several advantages of using tinplate for shipping containers. Firstly, tinplate is highly durable and provides excellent protection against corrosion, ensuring the safety and integrity of the goods being transported. Secondly, tinplate is lightweight yet strong, making it easier to handle and transport containers efficiently. Additionally, tinplate is easily recyclable, making it an environmentally friendly choice. Lastly, tinplate has a smooth surface which can be easily cleaned and sanitized, reducing the risk of contamination during shipping.

- Q: How is tinplate coated with anti-tarnish materials?

- Tinplate is coated with anti-tarnish materials through a process called passivation. This involves applying a thin layer of protective coating, such as chromium oxide or tin oxide, onto the surface of the tinplate. This coating acts as a barrier, preventing the tin from reacting with oxygen or other elements in the environment, thereby minimizing tarnishing and maintaining the appearance and integrity of the tinplate.

- Q: What are the different ways to customize tinplate packaging?

- There are several ways to customize tinplate packaging. Some common methods include printing or embossing designs or logos directly onto the tinplate, applying decals or labels, using different colors or finishes, adding metallic or matte effects, and incorporating additional elements like windows or handles. These customization options allow businesses to create unique and visually appealing tinplate packaging that aligns with their brand identity and stands out on the shelves.

- Q: How does tinplate contribute to the preservation of photographic equipment?

- Tinplate contributes to the preservation of photographic equipment by providing a durable and corrosion-resistant material for the construction of camera bodies, lens barrels, and other sensitive components. Its protective coating prevents the equipment from rusting or deteriorating over time, ensuring the longevity and functionality of the photographic devices.

- Q: Can tinplate be used for packaging beauty and skincare products?

- Yes, tinplate can be used for packaging beauty and skincare products. Tinplate is commonly used in the packaging industry due to its excellent durability, corrosion resistance, and ability to preserve the quality of the products. It also provides an attractive and professional appearance, making it suitable for beauty and skincare products that require an appealing presentation.

- Q: How is tinplate affected by extreme temperatures?

- Tinplate is generally resistant to extreme temperatures and can withstand both high and low temperatures without significant changes in its properties.

- Q: What are the different methods of labeling and branding on tinplate packaging?

- There are several methods of labeling and branding on tinplate packaging, including direct printing, lithography, embossing, and labeling with adhesive labels. Direct printing involves printing the design directly onto the tinplate using ink or paint. Lithography is a high-quality printing process that involves transferring the design onto the tinplate using a series of rollers. Embossing creates raised or recessed designs on the tinplate by pressing it with a die. Lastly, labeling with adhesive labels involves applying pre-printed labels onto the tinplate surface.

Send your message to us

TIN FREE STEEL FOR MAKING CROWN CORK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords