Tianjin Longkailai Oil Tubing: Industrial Applications, High-Quality Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

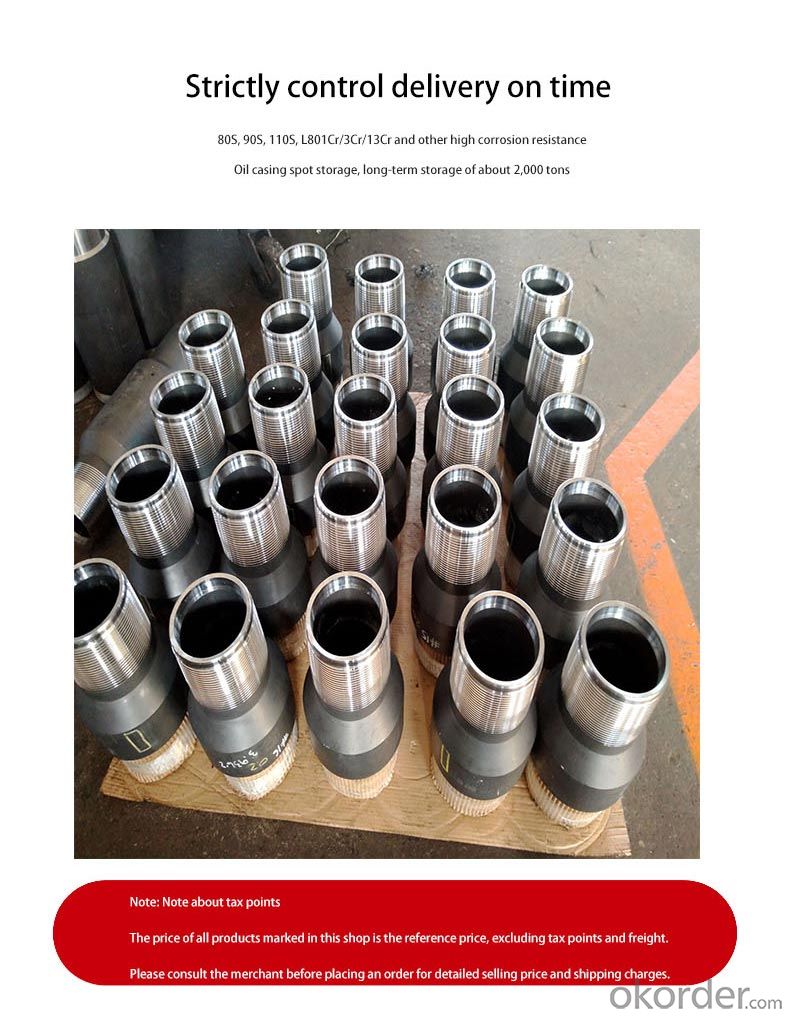

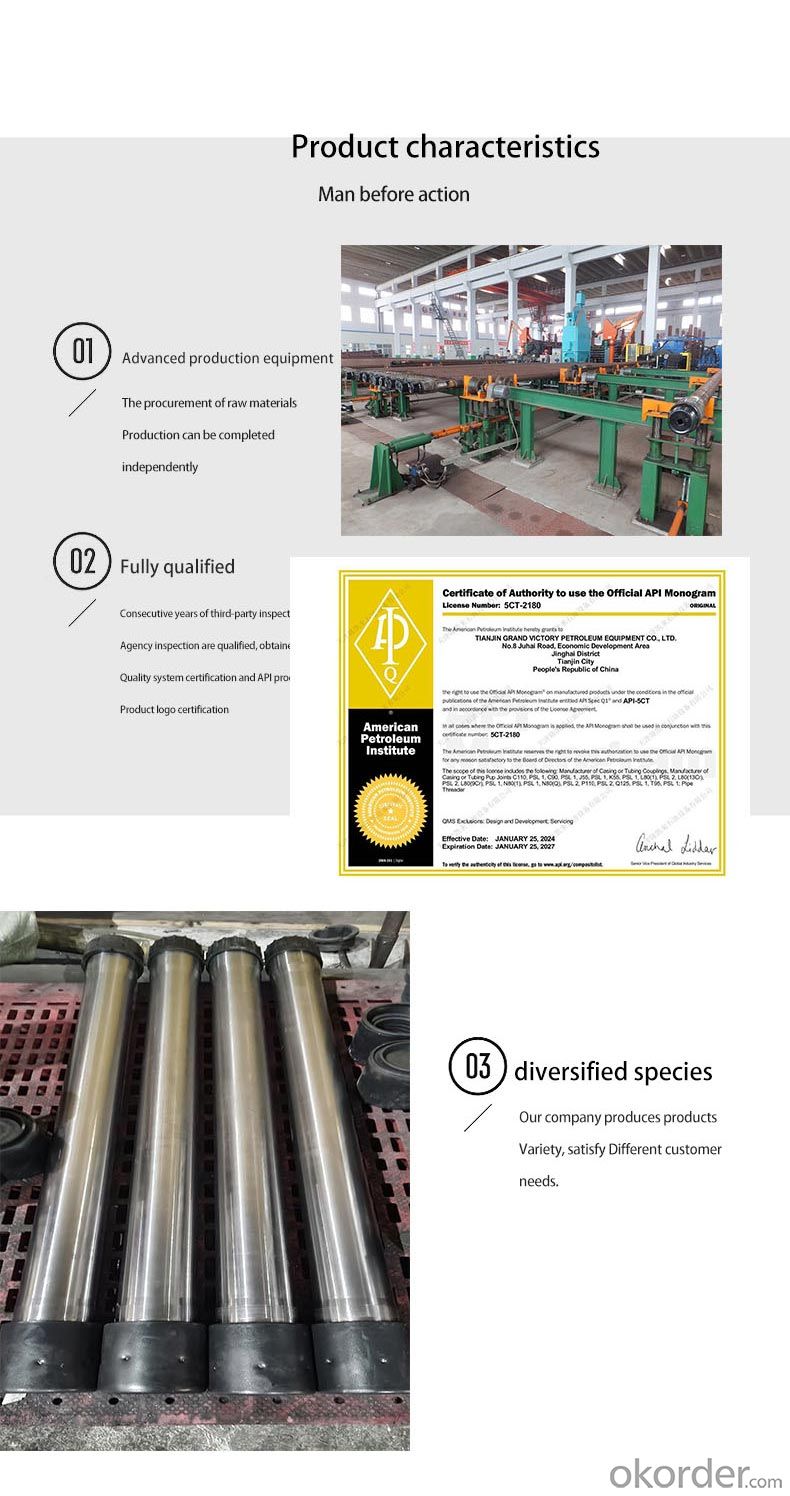

API 5CT J55/N80/P110 OCTG Casing & Tubing Manufacturer Direct

Comprehensive OCTG Solutions for Every Well Profile

As an API-licensed manufacturer, we eliminate intermediaries to deliver J55/N80/P110 casing and tubing with 15% cost savings. Our vertically integrated production process ensures full traceability from steel billet to finished product.

Technical Specifications

Material Science:

J55: 0.45% Mn, 0.25% C composition for shallow wells (≤8,000ft TVD)

N80: Quenched & tempered microstructure withstands 12,000psi collapse pressure

P110: 110ksi SMYS with Charpy V-notch impact ≥45J at -20°C

Threading Technology:

CNC-machined API LTC/BTC threads with ±0.003" pitch diameter tolerance

Optional VAM TOP connections for HPHT wells

Quality Assurance:

100% ultrasonic testing (UT) for laminations

Hydrostatic tested to 80% of yield strength

Applications

J55: Water injection wells, surface casing

N80: Intermediate casing in sour gas fields

P110: Production casing in 15,000psi reservoirs

Case Study

A Permian Basin operator reduced casing costs by 18% using our direct-shipment P110 casing for 35 horizontal wells, achieving 95% torque-turn compliance during running

- Q: How are steel pipes used in water transportation?

- Steel pipes are commonly used in water transportation as they are durable, strong, and resistant to corrosion. These pipes are used to transport water from sources such as reservoirs, treatment plants, or wells to different areas for domestic, industrial, or agricultural purposes. Steel pipes ensure the safe and efficient flow of water, preventing leakage and contamination, and are often buried underground or used in above-ground pipelines for long-distance water transportation.

- Q: What is the difference between internal and external coating of steel pipes?

- The main difference between internal and external coating of steel pipes lies in the purpose and location of the coatings. The internal coating is applied on the inner surface of the steel pipe to protect it from corrosion and ensure smooth flow of the contents within the pipe. It is commonly used to prevent contamination of the transported liquid or gas and to extend the lifespan of the pipe. On the other hand, the external coating is applied on the outer surface of the steel pipe to protect it from environmental factors such as moisture, chemicals, and physical damage. It helps to prevent corrosion and maintain the structural integrity of the pipe, especially in harsh conditions. Overall, while the internal coating focuses on the functionality and preservation of the transported contents, the external coating primarily aims at safeguarding the pipe itself from external influences.

- Q: What are the dimensions of a standard steel pipe?

- The dimensions of a standard steel pipe can vary depending on its intended use, but common dimensions include a nominal size (such as 1/2 inch, 1 inch, 2 inches, etc.) and a schedule number indicating its wall thickness (such as Schedule 40 or Schedule 80). The outside diameter of the pipe can range from small sizes of less than half an inch to large sizes of several feet. The length of a standard steel pipe is typically 21 feet, although shorter lengths are also available.

- Q: D108*4 what does "D108" mean by seamless steel tubes? What does "*4" mean?

- Seamless steel pipe: a pipe with a hollow cross section, used as a conduit for transporting fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials. Compared withsteel and roundsteelinsolid, flexural torsional strength in the same time, the weight is light, is a kind of economic section steel, widely used in the manufacture of structural parts and mechanical parts, such as the oil pipe, automobile transmission shaft, the bicycle frame and steel construction with scaffold with steel pipe manufacturing ring parts can be improved the utilization rate of materials, simplify the manufacturing process, material saving and working hours, has been widely used to manufacture steel tube.

- Q: What are the common factors affecting the flow capacity of steel pipes?

- The common factors affecting the flow capacity of steel pipes include the diameter of the pipe, the length and roughness of the pipe, the viscosity of the fluid being transported, and the overall pressure drop across the pipe.

- Q: How do steel pipes connect to other components?

- Steel pipes can be connected to other components using various methods, including welding, threading, flanges, and couplings. These connections ensure a secure and leak-proof joint between the steel pipe and other components, allowing for efficient fluid or gas transfer in various industries.

- Q: What are the different grades of steel used for manufacturing pipes?

- The different grades of steel used for manufacturing pipes vary depending on their intended applications. Some common grades include carbon steel, stainless steel, and alloy steel. Carbon steel is commonly used for general-purpose piping due to its affordability and strength. Stainless steel is preferred for corrosive environments or high-temperature applications due to its resistance to corrosion. Alloy steel, on the other hand, offers improved strength and durability and is often used for specialized applications such as oil and gas pipelines.

- Q: How are steel pipes used in the manufacturing of furniture?

- Steel pipes are commonly used in the manufacturing of furniture to provide structural support, such as in the construction of chair and table frames. They are also used as a base for attaching other materials, such as wood or fabric, and can be bent, shaped, and welded to create various designs and styles.

- Q: What's wrong with the 3PP anticorrosive steel tube?

- Most of the large pipes in our country use 3PE coating, and 3PP and 3PE coating belong to multilayer coating system. It consists of epoxy powder, intermediate layer adhesive and outer layer of PP (polypropylene) jacket.

- Q: What is the difference between seamless steel pipes and seamless alloy steel pipes?

- The main difference between seamless steel pipes and seamless alloy steel pipes lies in their composition. Seamless steel pipes are made from carbon steel, while seamless alloy steel pipes are made from various alloying elements such as chromium, nickel, or molybdenum. These alloying elements enhance the properties of the steel, making it more resistant to corrosion, higher in strength, and suitable for specific applications in industries like oil and gas, chemical, or power generation.

Send your message to us

Tianjin Longkailai Oil Tubing: Industrial Applications, High-Quality Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords