Three Side Sealing Food Grade Packing Laminated Bags

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

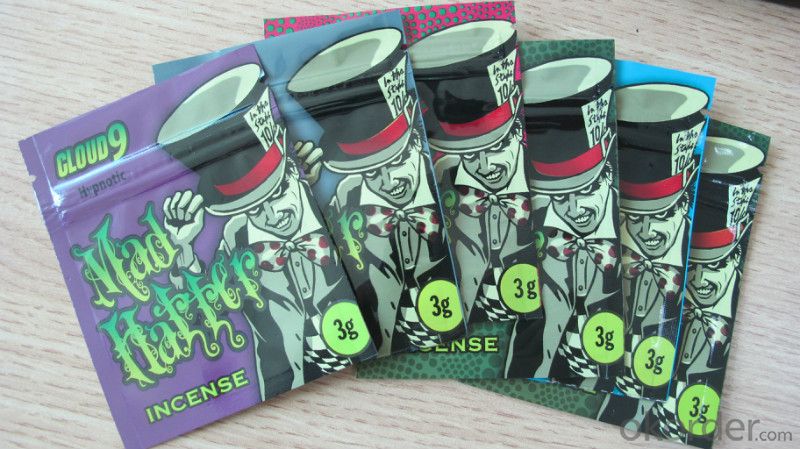

1. Description of Three Side Sealing Food Grade Packing Laminated Bags:

Three Side Sealing Food Grade Packing Laminated Bags are processing with imported materials, we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Three Side Sealing Food Grade Packing Laminated Bags mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Of Three Side Sealing Food Grade Packing Laminated Bags:

Excellent quality control

Experienced factory produced

SGS passed

3. Three Side Sealing Food Grade Packing Laminated Bags Photos:

4. Three Side Sealing Food Grade Packing Laminated Bags Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Three Side Sealing Food Grade Packing Laminated Bags:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What does "TM" mean in a food package?

- TM is common in foreign trademarks. It is the abbreviation of "trade mark" in English. "Trade mark" means "commercial mark" in Chinese, so "TM" means "trademark""

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Successful packaging must be consistent with the product positioning. Today's consumer groups are very different, for example, the elderly and young people on the acceptance of packaging design is very different, but also take moon cake as an example. The elderly may accept the traditional form of packaging (including graphic design, packaging design, structure design and so on) but the young people can accept the moon cake in the cake box, packed in ice cream box, metal box or even installed in the heavy metal in the punk style. You can't imagine an old lady in the supermarket, with a picture of a skull box filled with 8 pieces of moon cakes.

- Q: What are the characteristics of a good package?

- This mainly refers to the packaging can perfectly protect and preserve the product design in the material selection, structure, can effectively cooperate with transportation storage loading and unloading circulation operation; the consumer, carrying the goods, convenient preservation.

- Q: What material is the vacuum packing bag, please?

- And also consider the content and weight of the package to determine the reasonable use of the packaging materials. There is no static, and the right is the best.

- Q: What kind of material is the urea packing bag made of?

- Polypropylene (Polypropylene) is a semi crystalline thermoplastic (PP). With high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid base corrosion.

- Q: Dried fish vacuum packaging packing bag can not puncture

- With dried fish, we recommend the use of aluminum foil bag, also can be vacuumized. It has the function of avoiding light and keeping fresh.

- Q: What material should be used for transparent packing bags? How many cents do you want?

- PVC products for packaging containers, mainly for a variety of film and film. PVC containers mainly produce mineral water, drinks and cosmetics bottles, as well as packaging for refined oils. The PVC film can be used in CO extrusion with other polymers to produce low cost laminates and transparent articles with good barrier properties. PVC film can also be used for stretch or heat shrink packaging, used for packaging mattresses, cloth, toys and industrial goods.

- Q: What kind of packaging bag does polysilicon use?

- Polysilicon shall be packed in a clean polyethylene packing bag and sealed;

- Q: Plastic packing bag printing color

- A few silk thickness, a trace is 0.01mm, the more thick material, certainly the higher the price, so in ensuring the strength of your plastic bag, with thin point more money.

- Q: What can be easily removed from the words printed on plastic bags?

- A dye is a substance that makes certain colors adhere to the fiber and is not easily detached or discolored. The dye is usually dissolved in water, a part of the dye mordant dyes can adhere to the needs of the fiber. Dyes are substances that make fibers and other materials colored. They are divided into two main categories: natural and synthetic.

Send your message to us

Three Side Sealing Food Grade Packing Laminated Bags

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords