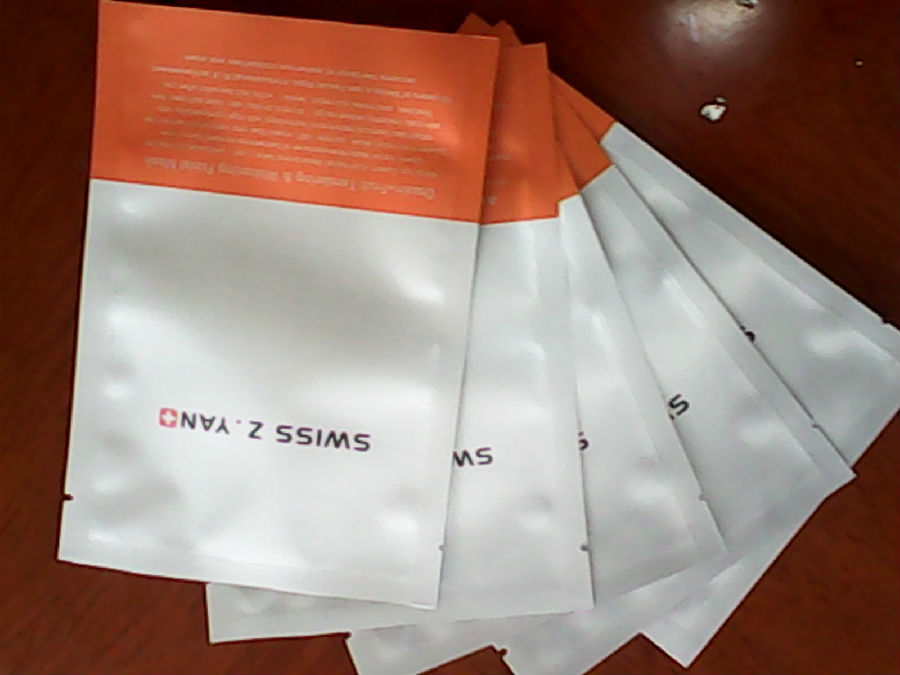

Three edge sealing face film bag

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000.0000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Can be customized

1. According to customer design requirements, printing 1 ~ 9 color on the bag, copperplate printing.

2. Bag composite materials can be divided into: PET outside the OPP. Matte film. Nylon

PET aluminum plating in the middle. CPP aluminum plating. Pure aluminium. Paper. Pearly membrane

In PE. CPP

Shrinkable film PVC, PET

Customers can choose materials according to their own product packaging requirements.

3. The bag type can be divided into: 3-side. The sealing bag. Organ bag. Zipper bag. Erect bag. Zipper bag. Bag mouth. Heterotypic bag. Card bag. Shrinkable film, etc.

4. Features: shading. Sealing strong. High-grade beautiful. Leakproof. High temperature resistant. Antistatic, etc

1. According to customer design requirements, printing 1 ~ 9 color on the bag, copperplate printing.

2. Bag composite materials can be divided into: PET outside the OPP. Matte film. Nylon

PET aluminum plating in the middle. CPP aluminum plating. Pure aluminium. Paper. Pearly membrane

In PE. CPP

Shrinkable film PVC, PET

Customers can choose materials according to their own product packaging requirements.

3. The bag type can be divided into: 3-side. The sealing bag. Organ bag. Zipper bag. Erect bag. Zipper bag. Bag mouth. Heterotypic bag. Card bag. Shrinkable film, etc.

4. Features: shading. Sealing strong. High-grade beautiful. Leakproof. High temperature resistant. Antistatic, etc

- Q: What are the characteristics of a good package?

- This mainly refers to the packaging can perfectly protect and preserve the goods in the design of material selection, structure, can effectively cooperate with transportation storage loading and unloading circulation operation; enable consumers to use the goods, carrying and preservation is more convenient. In addition, whether the packaging material will cause pollution to the environment, and whether recycling is also very important. Packaging industry is a scientific and systematic project, and the packaging design must take into account the scientific aspects of each link, which also reflects the combination of art and science characteristics.

- Q: What about the use of plastic bags?

- There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: What kind of material is the urea packing bag made of?

- Polypropylene (Polypropylene) is a semi crystalline thermoplastic (PP). With high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid base corrosion.

- Q: What kind of material is the food packing bag in general?

- Now the standard of living has improved, basically the food vacuum packed bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: The difference between a vacuum and a vacuum in a food package

- And packaging techniques like inflatable bags are called inflatable.

- Q: Is there any identification on the vacuum package?

- DOD on demand machine (drop) for short, called ink jet printer. The working principle: the nozzle is made up of several high precision valves. When the word is sprayed, the corresponding valve is opened and closed quickly. The ink is ejected by the constant internal pressure, forming characters or graphics on the surface of the movement.

- Q: Why is the higher the elevation, the more food bags inflate? From a physical point of view

- Because the food packaging bag is sealed, the air pressure inside is certain, with the elevation of the outside air pressure gradually decreased, which leads to gas bag outward extrusion pressure increased, so the higher the altitude, the food packaging bag inflated more.

- Q: Is the color of cement packing bags related to cement?

- Bags on both sides should be based on the varieties of cement with different color printing name and cement strength grade, Portland cement and ordinary portland cement Portland slag cement by using red, blue gray volcano; Portland cement and Portland fly-ash composite silicate cement by sleep and black or blue.

- Q: What kind of packaging bag does polysilicon use?

- Disposable material into a double-layer polyethylene bag, and then packing bags into the packing box or packaging barrel. Block polysilicon packaging specifications are net 5000g or 10000g per bag.

- Q: Plastic packing bag printing color

- A few colors, that is, a few colors, with several roll, one color needs a roll, and the more colors you have, the higher the cost of making the plate. Of course, the plate is calculated by area, the greater the size of your area, the higher the cost of making.

Send your message to us

Three edge sealing face film bag

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000.0000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches