The water used for large diameter welded pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Welded Steel Tube:

Welded Steel Tube is formed by drawing a solid billet over a piercing rod to create the hollow shell. We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of welded pipe and professioanl service.

2、Main Features of the Welded Steel Tube:

• High manufacturing accuracy

• The higher strength

• The small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Satisfy price

3、Welded Steel Tube Specification:

Standard | Grade | (MPa) | (MPa) | ||

Yield strength | Tensile Strength | ||||

API SPEC 5L | PSL1 | ||||

B | ≥241 | ≥414 | |||

×42 | ≥290 | ≥414 | |||

×46 | ≥317 | ≥434 | |||

×52 | ≥359 | ≥455 | |||

×56 | ≥386 | ≥490 | |||

×60 | ≥414 | ≥517 | |||

×65 | ≥448 | ≥531 | |||

×70 | ≥483 | ≥565 | |||

PSL2 | |||||

| Min | Max | Min | Max | |

B | 241 | 448 | 441 | 758 | |

×42 | 290 | 496 | 414 | 758 | |

×46 | 317 | 524 | 434 | 758 | |

×52 | 359 | 531 | 455 | 758 | |

×56 | 386 | 544 | 490 | 758 | |

×60 | 414 | 565 | 517 | 758 | |

×65 | 448 | 600 | 531 | 758 | |

×70 | 483 | 621 | 565 | 758 | |

Chemical Composition(%)

Standard | Grade | C | Mn | P | S | CEV |

Max | Max | Max | Max | Max | ||

PSL1 |

- | |||||

B | 0.26 | 1.2 | 0.030 | 0.030 | ||

×42 | 0.26 | 1.3 | 0.030 | 0.030 | ||

×46,×52,×56,X60 | 0.26 | 1.4 | 0.030 | 0.030 | ||

X65 | 0.26 | 1.45 | 0.030 | 0.030 | ||

X70 | 0.26 | 1.65 | 0.030 | 0.030 | ||

PSL2 |

0.43 | |||||

B | 0.22 | 1.20 | 0.025 | 0.015 | ||

1) Material: Grade:API 5L GR.B, X40, X42, X52, X56, X60, X65, X70.ST37/37-2,ST33,ST35.8,ST35.4.GB 9711.1/SY5037/GB3092

2) Specification range: OD: 406.4MM-1422MM (16”-56”)

Thickness: 8MM-50.8MM depends on OD

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Welded Steel Tube:

①How is the quality of your products?

We have many years business experience in this area, and we have professional engineer and manager team and sure we can provide you high quality production and professional service.

②How about price?

If you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

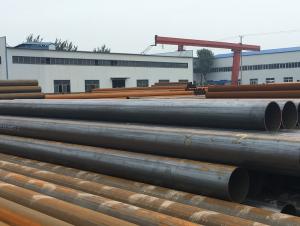

6、 Welded Steel Tube Images:

- Q: What are the different methods of testing steel pipes?

- There are several methods of testing steel pipes, including non-destructive testing methods such as ultrasonic testing, magnetic particle testing, liquid penetrant testing, and radiographic testing. Destructive testing methods like tensile testing, bend testing, and impact testing can also be used to assess the strength and integrity of steel pipes.

- Q: What is the cost of steel pipes compared to other pipe materials?

- The cost of steel pipes compared to other pipe materials can vary depending on several factors including the size, grade, and availability of the specific pipe materials. However, in general, steel pipes tend to be more cost-effective compared to other pipe materials. This is because steel is a widely available and versatile material that can be easily manufactured and fabricated into various pipe sizes and shapes. Compared to materials like copper, stainless steel, or plastic, steel pipes are often more affordable due to their lower manufacturing costs. Additionally, steel pipes have a longer lifespan and superior durability, which makes them a cost-effective choice in the long run. They are resistant to corrosion, withstand high pressure and temperature, and can be used in a wide range of applications including plumbing, construction, and infrastructure projects. It is important to note that the cost of steel pipes can still vary depending on market conditions, demand, and location. However, overall, steel pipes are generally considered to be a cost-effective option compared to other pipe materials.

- Q: How are steel pipes used in the construction of railways?

- Steel pipes are used in the construction of railways for various purposes such as laying tracks, supporting structures, drainage systems, and carrying utilities like water and electrical cables. They provide strength, durability, and corrosion resistance, ensuring the smooth functioning and longevity of railway infrastructure.

- Q: What are the common protective coatings used on the inner surface of steel pipes?

- The common protective coatings used on the inner surface of steel pipes include epoxy, polyurethane, and cement mortar coatings. These coatings provide corrosion resistance, prevent the formation of scales, and improve the durability and lifespan of the pipes.

- Q: What are the different methods of coating steel pipes for insulation?

- There are several methods of coating steel pipes for insulation, each with its own advantages and disadvantages. 1. Thermal Insulation Coating: This method involves applying a layer of thermal insulation material, such as mineral wool or foam, onto the steel pipe. The insulation material helps to reduce heat transfer and minimize energy loss. Thermal insulation coatings are relatively easy to apply and can provide excellent insulation properties. However, they may be prone to degradation over time and may require regular maintenance and replacement. 2. Corrosion Protection Coating: Steel pipes are often coated with corrosion protection materials, such as epoxy or polyethylene, to prevent rust and corrosion. These coatings act as a barrier between the steel surface and the surrounding environment, protecting the pipe from moisture, chemicals, and other corrosive elements. Corrosion protection coatings are typically durable and long-lasting, providing effective protection for the steel pipe. However, they may not provide significant thermal insulation properties. 3. Fusion-Bonded Epoxy (FBE) Coating: FBE coating is a popular method for both insulation and corrosion protection. It involves applying a layer of epoxy powder to the steel pipe and then heating it to create a strong, durable bond. FBE coatings provide excellent adhesion and resistance to corrosion, as well as some thermal insulation properties. They are commonly used in oil and gas pipelines and can withstand high temperatures and harsh environments. 4. Polyurethane Foam Coating: Polyurethane foam is often used as an insulation coating for steel pipes. It is applied by spraying or injecting the foam onto the pipe surface, which then expands and hardens to create a protective layer. Polyurethane foam coatings provide excellent thermal insulation properties and can be applied to pipes of various sizes and shapes. However, they may require special equipment and expertise for application and may be susceptible to physical damage or moisture absorption if not properly sealed. 5. Ceramic Coating: Ceramic coatings are another option for insulating steel pipes. These coatings are typically applied using a thermal spray process, which creates a layer of ceramic material on the pipe surface. Ceramic coatings can provide high-temperature insulation, corrosion resistance, and thermal shock protection. They are commonly used in industries such as power generation and aerospace, where extreme temperature conditions are present. However, ceramic coatings can be expensive and may require specialized equipment and expertise for application.

- Q: How do steel pipes handle extreme weather conditions?

- Steel pipes are highly durable and can withstand extreme weather conditions. They have excellent resistance to corrosion, which allows them to maintain their structural integrity even in harsh environments. Additionally, steel pipes have high tensile strength, making them resistant to bending, cracking, or collapsing under extreme weather events such as strong winds, heavy snow, or intense heat. Overall, steel pipes are a reliable choice for handling extreme weather conditions.

- Q: How are steel pipes used in the telecommunications sector?

- Steel pipes are commonly used in the telecommunications sector for various purposes. Firstly, steel pipes are used as conduit for underground cable installations. These pipes provide protection and support to the fiber optic cables that carry data and voice signals across long distances. The sturdy nature of steel pipes ensures that the cables remain safe from external factors such as moisture, rodents, and accidental damage. Additionally, steel pipes are used in the construction of telecommunication towers and masts. These structures require a strong and durable material to support the weight of antennas, transmitters, and other equipment. Steel pipes, with their high tensile strength and resistance to harsh weather conditions, are ideal for this purpose. Moreover, steel pipes are used for the installation of overhead communication lines. These lines are often suspended between poles or towers, and steel pipes are used as supports or brackets to hold the cables in place. The corrosion-resistant properties of steel make it a reliable choice for outdoor installations that are exposed to the elements. In summary, steel pipes play a crucial role in the telecommunications sector by providing protection, support, and durability to cable installations, tower constructions, and overhead communication lines. Their strength and resistance to environmental factors make them an essential component in building and maintaining reliable telecommunications networks.

- Q: Can steel pipes be used for sewage disposal systems?

- Yes, steel pipes can be used for sewage disposal systems. Steel pipes are commonly used for underground sewage lines due to their durability and resistance to corrosion. They can efficiently transport sewage from residential, commercial, or industrial areas to sewage treatment plants or disposal sites.

- Q: Seamless steel pipe and welded pipe what is the difference?

- Identification method: see the inside of the pipe, because the external, will deal with the welded pipe is inside a gap, you can see some, some, is not easy to see, you can slowly by hand touch, or see the specifications are relatively thin, welded pipe

- Q: Can steel pipes be used for underground utility lines?

- Yes, steel pipes can be used for underground utility lines. Steel pipes are known for their durability and strength, making them suitable for underground applications. They can withstand heavy loads, pressure, and corrosion, which are essential factors for utility lines that are buried underground. Additionally, steel pipes can be welded or threaded together, allowing for easy installation and maintenance.

Send your message to us

The water used for large diameter welded pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords