The production department smooth magnesium oxide board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

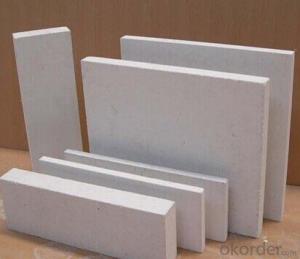

The production department smooth magnesium oxide board:

Onekin green board is a kind of environmental-friendly board which is widely used in construction and decoration.

It is a new type non-flammable material made of lightweight materials. It's made from magnesium oxide, magnesium

chloride, fly ash , plant fiber etc. the highly purified MgO is used as the main fireproof material, fly ash and

plant fiber as filling materials, the high quality MgC12 as the main cementing material to solidify other

materials.

1,Superior Fireproof Performance

Non-combustible panel, not combusted at 800℃ and no flames at 1200℃

2,Waterproof

Stable physical performances will not be effected even in cold-dry or humid weather conditions.

3,Environmental

Asbestos free, No radioactive elements like formaldehyde, benzene etc and no irritating harmful odor

4,Lightweight and anti-seismic

Lightweight characteristic lowers the interior wall weight up to 60% of the building, increasing the usable areas

5,Sound and heat insulation

Outstanding sound-insulating and heat-insulating (energy-saving) performances provide a cozy living atmosphere.

Details size:

| Raw Mterials | MgO, MgCl2, fiberglass mesh, non-woven cloth | ||

| Standard Size(mm) | Density(t/m³) | Weight(kgs) | Loading pieces(20GP) |

| 2440×1220×3 | 1.0-1.2 | 11 | 1360pcs |

| 2440×1220×4 | 1.0-1.2 | 13 | 1240pcs |

| 2440×1220×5 | 1.0-1.2 | 15 | 1008pcs |

| 2440×1220×6 | 1.0-1.2 | 18 | 850pcs |

| 2440×1220×8 | 1.0-1.2 | 24 | 640pcs |

| 2440×1220×9 | 1.0-1.2 | 26 | 572pcs |

| 2440×1220×10 | 1.0-1.2 | 28 | 512pcs |

| 2440×1220×12 | 1.0-1.2 | 34 | 420pcs |

Physical Properties:

Item | Size | Standard Documents | Standard value | Test Value |

Fireproof | 2440×1220×8mm | GB8624-2006 |

| A1 |

Density | 2440×1220×8mm | Jc688-2006 | 1.0 t/m³<ρ<1.2 t/m³ | 1.17t/m³ |

Flexural Strength | 2440×1220×8mm | Jc688-2006 | ≥10MPa | 11.8MPa |

Impaction resistance | 2440×1220×8mm | Jc688-2006 | ≥2.0 kJ/m² | 5.9kJ/m² |

Water content | 2440×1220×8mm | Jc688-2006 | ≤8% | 2.8% |

Drying shrinkage | 2440×1220×8mm | Jc688-2006 | ≤0.3% | 0.3% |

Wet inflation | 2440×1220×8mm | Jc688-2006 | ≤0.6% | 0.39% |

Screw holding | 2440×1220×8mm | Jc688-2006 | ≥20N/mm | 76.5N/mm |

Anti-halogen | 2440×1220×8mm | Jc688-2006 | No water drop, no damp | Pass |

Chloride content | 2440×1220×8mm | Jc688-2006 | ≤10% | 7.2% |

application:

interior Applications: Exterior Applications:

1) Wall board 1) Sheathing

2) Backer board 2) Soffit- Ventilated and Non Ventilated

3) Underlayment 3) Siding

4) Fireproof board 4) Trim materials

5) Ceiling board

1,Fireproof Grade A1

6mm: ≥1 hour

6-12mm:1-2 hours

12mm : ≥2 hours

2,Water absorption: about 18%

3,Expansion in water:≤0.3%

4,Sound insulation: 29 dB (6mm)

5,Thermal conductivity: 0.161 W/(mK)

6,100% asbestos free

7, No toxicity

8,Resistance to growth of mold and mildew

9, Insect-resistance

- Q: Wardboard thickness is about how much

- Wardboard thickness of the need to reach 18 mm, the thickness of the best plate up to 25 mm, which is like building a house had to bear the same wall, the structure is reasonable to build a solid and stable house.

- Q: How is Fuqing plate?

- Selection: Most of the raw materials are selected from the international forest units recommended by the Malaysian strategic partner "Global Wood", and China's most suitable Chinese fir growing climate in the Nanling area with more than 30 years of age, large diameter Chinese fir. Material nature is stable, the original grain full appearance.

- Q: Glasses frame is good or tungsten titanium steel plate is good or good

- One, steel glasses, evolved to a Chinese name, South Korea called tungsten titanium (ULTEM transliteration) glasses, also known as PEI (material referred to) glasses. Plastic glasses, in 2017 in Korea and Japan has been popular, in July 2017, began to seize the Chinese mainland market. Before October 2017, the domestic market is mainly South Korea's imports of plastic glasses, after October, the domestic began to have production, but because of the characteristics of the material, plastic glasses are high temperature and high pressure injection molding, the domestic injection molding process does not meet the requirements, resulting in Multi-bubble, easy to break, poor permeability. At the same time, the domestic color of plastic glasses for the spray up, so easy to fall off, off the skin, South Korea for the plating process. At present, due to the proliferation of the concept of plastic glasses, the domestic shoddy, with other materials to act, most of them only have a real steel glasses light, and not with high-strength plastic, high toughness, no fade. Domestic steel production and South Korea distinction: South Korea imports must be high-end, and now South Korea is also required under the Chinese market to do low-quality low-priced products) Distinguish one: the basic domestic all are matte, can not do bright, South Korea imports most of the bright color, according to the needs of matte color; Distinguish between two: the domestic color for the spray color, so it looks like a layer of leather package, South Korea for the plating process, tight adsorption, strong texture; Distinguish between three: the domestic injection molding process is not reached, the permeability is not good, so all the spray color, do not do character, Korean production is transparent color, that is translucent color, crystal impurity

- Q: The difference between plate and wire

- The difference between the plate and the wire is the difference between the size of the material and the difference between the use: Wire is a diameter of 5-22mm hot rolled round steel or equivalent of this section of shaped steel. Due to wire rod in the form of delivery, it is also known as the wire rod. Wire section circumference is very small, the common product specifications diameter of 5-13mm. According to the different rolling mill can be divided into high-speed wire (high line) and ordinary wire (ordinary line) two. Wire is generally made of ordinary carbon steel and high quality carbon steel. In accordance with the distribution of different types of steel and use, wire, including ordinary low-carbon steel hot-rolled disc, high-quality carbon steel wire rod, carbon wire rod, quenched and tempered wire rod, wire rope with wire rod, As well as stainless steel wire rods and so on. The plates are usually made of standard-sized flat rectangular building material panels for wall, ceiling or floor components. Also refers to the forging, rolling or casting made of metal plate. Divided into thin plate, medium plate, thick plate, special thick plate, usually made of standard size flat rectangular building material board. Plate product shape flat, thick and thick ratio, the unit volume of the surface area is also great This shape features to bring its use on the characteristics: (1) large surface area, so inclusive capacity, in the chemical industry, containers, construction, metal products, metal structures, etc. have been widely used; (2) can be arbitrarily tailored, bending, stamping, welding, made of various product components, the use of flexible and convenient, in the automotive, aviation, shipbuilding and tractor manufacturing and other departments occupy an extremely important position; (3) can be bent, welded into various types of complex sections of steel, steel, large I-beam, channel and other structural parts, it is called "universal steel."

- Q: PCB plate manufacturers are famous what

- Sunrise, Matsushita, Arlon, Nelco, Rogers, Tanconic, polyflon, etc.

- Q: Some of the real use of solid wood, mostly pine and fir Kazakhstan, there are oak; and some with joinery, both from the service life and environmental protection point of view are their advantages and disadvantages, the cost is certainly a lot of difference. All the students, whether to give advice, 5 square meters of place want to do tatami, with solid wood and joinery cost and reason!

- Wuliangmi platform plus tatami three thousand dollars it is recommended with blockboard solid wood easy to deformation plus geothermal finish

- Q: Is the picture below the S modeling faculty do very stiff want to achieve this and exactly the same effect Thank you!

- Hello, you should explain what it is to use, where to use. We do the shape of the ceiling, then, are generally made with multi-layer board, in accordance with the requirements in the multi-layer board first arc, and then use the curve machine or trimming machine and other equipment cut.

- Q: There is the cloakroom between those hardware is not a fixed size of what? Help you heroes

- Solid wood finger plate Refers to the board, also known as integrated board, Glulam, refers to the material, that is, after the deep processing of solid wood small pieces like "fingers" stitching the same plate, due to the use of jagged wood between the board, similar to the fingers Cross-docking, so called the board. As the wood between the cross is a combination of such a combination of the structure itself has a certain binding force, but also because there is no need to stick up and down the surface of the panel, Gu its use of the plastic extremely small. Advantages: due to the connection of solid wood panels less, with less glue, so the environmental protection coefficient relative Higher. With easy processing, cutting, drilling, sawing and forming processing. Disadvantages: solid wood finger plate easy to deformation, cracking. Good solid wood finger board quality is guaranteed but the cost is higher. 5. Multi-layer solid wood board Multi-layer solid wood board to criss-crossing the multi-layer plywood as the substrate, the surface of high-quality solid wood paste or technology wood for the fabric, the cold, hot, sanding, health and other processes made of several processes. As a result of multi-layer solid wood board is not easy to deformation characteristics and good regulation of indoor temperature and humidity of the excellent performance, surface solid wood paste leather material and natural wood texture and feel, so more selective. Therefore, much consumers of all ages. Multi-layer solid wood board with good structural stability, not easy to deformation. As the vertical and horizontal gluing, high temperature and high pressure, from the internal stress to solve the deformation of solid wood defects. In the production process using self-made high-quality environmental protection glue (corn starch), so that the product limit of formaldehyde release to meet national standards, green.

- Q: The most commonly used gas shielded welding consumables are certainly different from the material being welded. The silicon content and the manganese content in the wire are higher than those in the material. And the sulfur content inside the wire is much lower than the sulfur content of the base material being welded. Here, the role of silicon manganese is in the welding arc, in the welding bath for deoxidation of the chemical reaction, the other silicon manganese infiltration of the base metal can also improve the strength and plastic of the weld metal.

- The most commonly used gas shielded welding consumables are certainly different from the material being welded. The silicon content and the manganese content in the wire are higher than those in the material. And the sulfur content inside the wire is much lower than the sulfur content of the base material being welded. Here, the role of silicon manganese is in the welding arc, in the welding bath for deoxidation of the chemical reaction, the other silicon manganese infiltration of the base metal can also improve the strength and plastic of the weld metal. ??? The metallographic structure of the weld metal is generally a coarse tissue, which is very poor in mechanical properties. The structure of the base material to be welded is generally fibrous forged tissue, and the mechanical properties are much better. However, due to the weld metal into a certain amount of silicon manganese, the strength of plastic have been improved. In general, the weld metal is much better mechanical than the low carbon steel base metal.

Send your message to us

The production department smooth magnesium oxide board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords