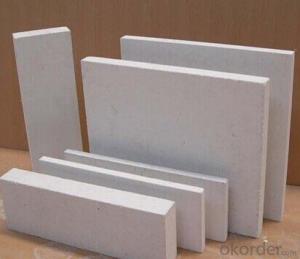

high quality magnesium oxide board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

high quality magnesium oxide board

Product introduction:Xinlong magnesium oxide board is made of magnesium oxide, magnesium chloride, glass fiber cloth of middle alkali , expanded perlite, sawdust and other auxiliary materials and additives, which is advanced process, stripping, conservation, anti-reversion halogen processing and drying processes .What's more it is popular building materials in the world . It is divided into building materials and fire resistance board according to processes, formulas.Its technical indicators are completely compliance with the requirements of GB25970-2010 “inorganic non-combustible composite board”standard.

magnesium oxide board Features:

Serial No | Inspection Items | Inspection Methods | Technique Data | Test Results | Conclusion |

1 | Density,g/cm3 | GB/T 7019-1997 | / | 1.04 | / |

2 | Dry State Bending Strength,MPa | GB/T 7019-1997 | ≥6 | 8 | Qualified |

3 | Saturated Bending Strength,MPa | GB/T 7019-1997 | ≥3 | 6 | Qualified |

4 | Moisture absorption,% | GA 160-2004 | ≤0.20 | 0.14 | Qualified |

5 | Impermeability | GA 160-2004 | No Water Drop,No Getting Damp | Compliance with Requirements | Qualified |

6 | Combustion Performance |

|

|

|

|

| In-Furnace Temperature Rise,°C | GB/T 5464-1999 | ≤50 | 8 | Qualified |

| Fire Duration,S | GB/T 5464-1999 | ≤20 | 0 | Qualified |

| Mass Loss Rate,% | GB/T 5464-1999 | ≤50 | 47.0 | Qualified |

Main application areas:

Fire resistance board series: used in the tunnel ceiling, steel structure column, beam, horizontal floor, fire partition wall, room dividers.

Decorative board series: used in hotels, office buildings, residential renovation.

Substrate Series:used in ceiling, partition, fireproof door core, warehouse board and lining board.

Sound-absorbing board Series: subways, bus stations, theaters, factories and other public buildings.

magnesite

It is not suitable for building materials because its content is less then 60%, Light burned magnesium oxide powder price is 2 times the price of magnesite what's more it has much impurities .Fireproof performance is worse than light calcined magnesite .

Light burned magnesium oxide powder

It is suitable for building materials and fireproof materials because its content is more then 85%, Light burned magnesium oxide powder price is 2 times the price of magnesite what's more no impurities .Its fireproof performance is betterr than magnesite .

More details:

MGO fireproof sheet is a kind of environmental-friendly fireproof board widely used in construction and decoration. It's made from magnesium oxide, magnesium chloride, fiberglass mesh, sawdust, perlite etc. We use, highly-purified active MGO as the main fireproof material of board, high-quality MgCl2 as the main cementing material to solidify other materials, alkali-resistance fiberglass mesh to ensure the high strength of board, soft sawdust and light non-combustible perlite as filling materials.

MGO fireproof sheet enjoys strong points in more fields compared with the plasterboard and the traditional partition board, either in the decoration for modern construction or the fire resistent division for the industrial workshops

Features of the products :

1. Strong fireproofing capability: All the specifications of this product has reached the requirement of GB8624 fireproof level A and JC688-2006.

2. Good shockproof capability: This product is designed with many layers of high-strength fiber webs, which can effectively absorb part of the energy from the earthquake to avoid the instantaneous collapse of the isolation wall.

3. Smooth and scratchproof face: Advanced European and American production technology and recipes is introduced for this product, thus the turned-out board material is of smooth face and high hardness, collision and impacting will not result in depressions and scratches.

4. Good safety performance: This product is 100% free of asbestos and radiation, nor will it create the organic substance harmful to human bodies.

5. Superior performance in sound insulation and heat insulation: When used as the partition, this product can be filled inside to absorb sound, whose performance in sound insulation is better than the single brick wall meanwhile the cold and green house effect is raised, which saves energy and increases the economic benefit.

- Q: Will the experts: acetic acid plate and the difference between acrylic, resin sheet

- Organic chemical chemical industry is so complicated, only conventional products conventional method, that is, specify the specific conditions. And that are colorless and transparent products it, designated conventional cellulose acetate plate, conventional acrylic plate, conventional thermosetting resin board. Among the three, you can see the degree of colorless translucent to the highest acrylic, followed by resin, acetic acid again. You can see heat conditions, heating to one hundred and fifty degrees above, acrylic will soften the flow, the resin will be soft but not flow, and then raise the temperature, acetic acid will melt. Look at the situation of specific solvents, dip chloroform (chloroform) wipe the surface, acrylic solution, slightly soluble acetic acid, resin unchanged. Of course, for the specific different varieties, the situation is very different

- Q: How about Tiantuo plate

- How to buy plate (1) whether it is environmentally friendly. According to the provisions of the indoor building materials formaldehyde emission must be less than or equal to 1.5mg / l, if more than 5mg / l is exceeded. (2) wood moisture content. When the wood moisture content is higher than the equilibrium moisture content of the environment, the wood will dry shrink, otherwise it will absorb moisture expansion. The main cause of wood cracking and deformation is that the moisture content is too high or too low. (3) Do not just cheap. Low-priced materials are usually sold and crushed and formaldehyde seriously exceeded the material, should be to the regular market to buy, it is best to buy a brand of materials. (4) the purchase of wood flooring when the tree species do not have to worry about the name, the election is the most important dealer.

- Q: What is the difference between steel sheet and coil?

- Coil is the factory roll because the length is long to roll up with C said, such as: 2.75 * 1500 * C Tablet is the factory in the hot-rolled production line before the cutting plate stability of the specifications cut into a board, such as: 2.75 * 1500 * 6000

- Q: Recently we received a lot of customers to reflect, said to buy their own snowflake sheet, the results go back after use, the taste is great, even worse, the board labeled furniture has not long, there has been damp deformation situation. Customers are very angry, we are also confused.

- Recently we received a lot of customers to reflect, said to buy their own snowflake sheet, the results go back after use, the taste is great, even worse, the board labeled furniture has not long, there has been damp deformation situation. Customers are very angry, we are also confused. However, it is the most environmentally friendly sheet on the market, and the formaldehyde emission of the E1 grade (0.5 <formaldehyde emission <1.5) sheet is similar to that of the same type of sheet, although the plate price is relatively high. The brand claims to be the E0 level release standard. Many customers are directed at the brand of snow. We do is the conscience of business, bright business, snow shop in the flagship store sold to our customers are the lowest price, the floor is very low profit, are by running the amount to earn meager profits, of course, each A sheet of hair issued to the we are checked, and will never appear cracks, flaws. In the flagship store to buy Xuefeng ecological board, we will carefully selected for the customer out of the same batch of goods, to ensure a high degree of unity of the panel color. Will never appear shoddy situation to deceive consumers, which is undoubtedly pick up the stone hit his feet, we will never make this self-destructive brand image of the act. We compare the documents, compared to the decorating company, and finally concluded: these customers are not buying snowflake sheet. Now the market is not a lot of qualified small decoration company, the name of the shiny brand name, to higher than the price of ordinary plate, to sell the brand of wooden plywood, often do not understand the decorating industry customers Deceived, which is our snow brand is also a damage.

- Q: Home search needs a thin sheet of paper need to be able to paste the tile as if it is not posted it

- With calcium calcium board or fiber cement board can be, but it is best to fix the board fixed in the brick surface coated with a layer of waterproof plastic, dry and then paste. There is a board with glass glue or stone stickers, but a damp, the effect is not good.

- Q: TR90 memory board frame is what?

- In fact, there is no such frames, TR90 frame with the plate is different. 1, from the material comparison: TR90 frame is the use of nylon material (also known as nylon 12 or PA12), is the most popular ultra-light frame material, with light weight, good toughness, super safety and other characteristics, with super Flexibility, wear in motion will never break. (Except fake and shoddy products). Plate frame is the use of acetate fiber or propionic acid fiber. Injection molding or suppression of grinding production. 2, the process comparison: TR90 frame process complex, the injection of glass factory and spray paint process requirements are relatively high. Plate rack: Although the plate rack less painting, but in the work than the TR90 frame process to be much more, more complex process. 3, the use of comparison: TR90 Frame: light weight, comfortable to wear, more secure, more difficult to deformation. The only drawback is that it will fade. Plate frame: the same size of the frame relative to the TR90 frame will be more weight, the bridge of the nose will have the feeling of oppression, comfort is not as TR90 frame, flexibility and safety than the TR90 frame slightly worse. The advantages of three-dimensional sense of strong, three-dimensional edges and corners of the TR90 frame can not be compared, but also not out of color. )

- Q: Buy Yiyang plate how to do the problem?

- And later consulted their customer service, if you buy back if the inspection found a problem can immediately retreat, found within 24 hours of quality problems can immediately exchange, if the time found within three days of quality problems can be negotiated exchange, in short, the quality is still more secure The

- Q: Is the cement pressure plate and the cement fiber board a plate? Is there a difference?

- Cement fiberboard and cement pressure plate is a product of two names, in fact no difference. The cementitious materials are cement, and the reinforcing materials are fibers (asbestos fibers and / or cellulose fibers). The name of the fiberboard emphasizes the reinforcement of the material 'fiber'; 'pressure plate' name emphasizes the production process, the use of presses on the board green pressure, squeeze out the water and compaction, improve the board's density and strength. 'Cement fiberboard' is a more traditional name, but in recent years is also known as 'cement pressure plate'. Advantages and Disadvantages of Cement Fiberboard Advantages: cement fiber pressure plate as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and commercial applications in the ceiling ceiling and partition, home decoration , Furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall. Calcium silicate board processed into the ceiling, with resistance to subsidence, moisture, no dust, non-flammable and other characteristics, an effective solution to mineral wool board gypsum board easy subsidence, short life defects. Calcium silicate board, fiber cement pressure plate is the ideal decoration of the permanent building plate. Walls, ceiling also applies to the wall, the activities of the floor, table, billboards, goods cabinets, kitchen latrines, goods cabinets, fire Pipe, furniture liner, fire door lining. Disadvantages: easy to cause crevice cracking, and deal with the gap is too much trouble. (Thermal expansion and contraction is relatively strong in the reason)

- Q: How much is a cafe?

- White wax and red oak from the North American material of ash and red oak, such as according to the domestic material, wax for the ash, oak for the oak. These two kinds of wood is a good wood, such as produced for North America, The price is also closer to the two, such as white oak is more expensive. These two kinds of wood have long been used in furniture production, especially in American furniture. American furniture, the most common wood is in turn: white oak, Red rubber, white wax, cherry, maple, black walnut etc ... so the specific choice of which kind of wood, need to see your personal preferences.But if you can not determine whether the wood produced in North America, I suggest you use red rubber. At present, a large number of domestic use of Russian Fraxinus instead of North American white wax, low price. Color yellowish, but can be bleached. Furniture material marked wax. The red oak of the argument generally refers to the North American material, Russia's oak white and yellow, production Out of the furniture generally oak, rather than specific to white rubber or red oak

- Q: Computer tables, two kinds of sheet: particleboard / melamine board MDF / fiber board which is better material? Thank you!

- Computer table of the plate, it is recommended to choose particleboard / melamine board. It is not recommended to use MDF Reason: 1. The former high environmental protection factor 2, the former moisture resistance is good 3. The former than the latter grip nail force is good, easier to fix.

Send your message to us

high quality magnesium oxide board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords