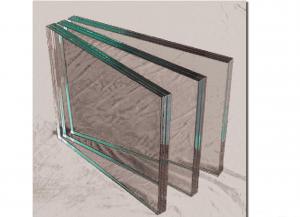

Tempered Glass-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tempered Glass is a kind of safety glass with perfect quality.

Features:

1、It can maintain the original flatness and transmittance of float glass with no wave and buckling after tempered.

2、Stress Marks on a single piece or multiple pieces of tempered glass cannot be seen with naked eyes under any natural light.

3、The distortion caused by airflow marks and white fogs is removed, which is difficult for common tempered glass.

4、Furthermore, good transmittance is maintained.

Specifications:

Thickness: 5-25mm

Size:

2440*8000mm

300*300mm

customized size

Applications:

It is mainly used in curtain walls, shower rooms, furniture, guardrails, pool fences, etc.

- Q: What kind of raw materials should be used in making FRP?

- The raw material of glass fiber reinforced plastic is divided into two kinds: reinforced material and base materialThe reinforced material of glass fiber reinforced plastic is composed of glass fiber and its fabric. It is the main load-bearing component material of glass fiber reinforced plastics, and has a direct impact on the strength and stiffness of FRP

- Q: What role does zircon sand play in the production of glass? Is it a raw material for glass or a production process?

- Zircon sand is the most important zirconium containing mineral, which has the widest distribution, largest reserves and most types in zirconium minerals. It is a kind of mineral with zirconium silicate as the main component. Zircon sand is the main raw material for preparing zirconium, hafnium and many kinds of zirconium products. It has the characteristics of high melting point, low thermal conductivity and small coefficient of linear expansion. It is widely used in metallurgy, casting and other industries.Zircon sand (Gao Yingshi) is highly resistant to heat and has a melting point of 2750. Acid corrosion resistance. 80% of the world's direct use in the foundry industry, ceramics, glass industry, and the manufacture of refractory materials. A small amount used in ferrous alloys, pharmaceuticals, paints, tanning, abrasives, chemicals, and nuclear industries. Very little is used in smelting zirconium metal.

- Q: How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- To have good quality, if the quality of other yarn nets, there may be broken.

- Q: What is the difference between acrylic board, lotus board, organic board and PVC board?

- Lotus board (also known as Teflon plate) lotus board single sided composite PVC foam board, ABS lotus board, acrylic panels, ABS surface can not be used for outdoor. Furong sheet is a new kind of chemical material. It is made of polyethylene as main raw material, adding various auxiliaries, and has been formed by chemical bridge foaming, and the single side composite PVC board.

- Q: What is the difference between white float glass and ordinary float glass?

- The iron oxide content of ultra white float glass is low, so the raw materials (sand or sandstone) to low iron content, iron content can be the best sand control below 0.03%

- Q: Why is toughened glass broken?

- There are a variety of predisposing factors. Tempered glass explodeFor example, A. before the installation of glass is accidentally damaged, like chipping, knocked the feet, because the glass is tempered around the weak area, its strength even weaker than the non tempered glass, but this part of the damage are not likely to cause the glass immediately burst, but changed the internal stress of glass. When the upper wall is used, the internal stress changes gradually, which breaks the glass.B. such as differences in temperature after installation. As you say, temperature, weather, and so on, will make the internal pressure of the glass partial uneven, thus causing burst.Is there a correct size for the C. installation?. If the installation is too tight, the specifications are not appropriate, it will cause stress changes inside the glass, causing a burst.D. the rest is external force, including impact, extrusion and so on. It's not just human impact, or other things, or even wind in nature. If the glass does not fall on the ground, there will be the point of impact (if it is obvious, there will be explosive, Hu Dieban) these can be invoked, but if in the proceedings can only be said to be a possibility, because you have no evidence to prove that. In the domestic situation, the glass manufacturers generally compensate for the glass trouble.

- Q: What is a hollow glass?

- At present, the domestic glass mainly has three kinds: (a) aluminum type sealant; (two) aluminum type double sealing; (three) composite sealing strip type insulating glass. Aluminum type sealant, because of its poor sealing performance, easy to cause the glass into moisture, dew and frost, service life short, the hollow glass gradually eliminated. The raw materials of two kinds of hollow glass is mainly: glass, aluminum, gusseted, butyl rubber, two-component polysulfide rubber or silicone rubber, composite desiccant, underground sealant.

- Q: What are the cutting and cutting of acrylic and aluminum-plastic plates?

- Acrylic comes from English Acrylic, generic name for Acrylic acrylic and methacrylic acids chemicals. Including monomers, plates, aggregates, resin and composite material, acrylic acid methyl ester by methyl monomer (MMA) polymerization, namely polymethylmethacrylate (PMMA) organic glass plate, "organic glass" from the name "Oroglas" (a PMMA), from the "Organic Glass" (organic glass).

- Q: Which is the best solar water heater tube?

- The color of the vacuum heat collecting tube is mainly blue and black, and the overall chromatic aberration is small. But black does not indicate the quality of vacuum heat collecting tube is good, because some manufacturers in order to cover up variegated, often made of pure black film. In fact, there is a certain error in the color of the vacuum heat collecting tube, which is unavoidable, and does not affect the heat collecting efficiency of the vacuum heat collecting tube.

- Q: Why is the process of glass toughened always broken?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 2003 |

| Annual Output Value | |

| Main Markets | Europe; Asia; Mid-East |

| Company Certifications | ISO9001:2000; ISO9002 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shandong,Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 3000,000 square meters |

| No. of Production Lines | 26 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Tempered Glass-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches