Tapered Roller Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descripcion

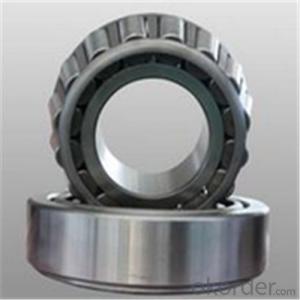

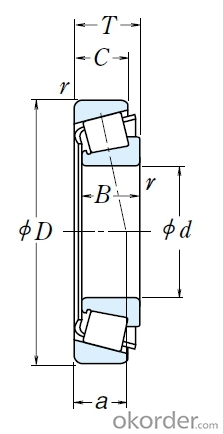

Single-Row Tapered Roller Bearings

The most basic and widely used tapered bearing, the single-row type consists of the cone assembly and the cup. It is usually fitted as one of an opposing pair. During equipment assembly, single-row bearings can be set to the required clearance (endplay) or preload condition to optimize performance.

Double-Row Tapered Roller Bearings

Double- or two-row tapered roller bearings feature double cups and two single cones. They are available in a variety of configurations for general industrial and automotive applications.

Four-Row Tapered Roller Bearings

Four-row bearings provide maximum capacity in minimum space, combining the inherent high-load, radial/thrust capacity and direct/indirect mounting variables of tapered roller bearings.

Their main application is on the roll necks of rolling mill equipment. All four-row bearings are supplied as pre-set matched assemblies with all components identified to ensure correct installation sequence.

Tapered roller bearings (TRBs) utilize rolling elements that are shaped like a truncated cone , and are constructed so that all tapered surfaces converge at a common apex point on the bearing centerline to yield true rolling motion. Tapered roller bearings are generally used in lower speed, high load applications and are capable of absorbing radial and/or axial loads. The internal angles may be designed to tailor the bearing to the loading demands of a specific application. Tapered roller bearings are a separable two-piece design (cup and cone) ; which, allows the end-use to optimize the internal clearance (and life) for each application when the bearing is mounted. PEER primarily manufactures single row (TS), sealed single row (LA), and matched set tapered roller bearings.

F&Q

Q:How long es cycle of bearing life?

A:According to international standards, at least a year and a half , up tu 2 years

Q:How to maintenance bearing

A:Add to lubricantes on time

Q:Have diagram for bearing

A:The small one no have, large bearings will provide diagram

- Q: Taper roller bearings are used on my motor. Serious damage occurred during use. Please help me analyze the possible causes of damage! Thank you

- But it is worth noting that you must control your parts tolerances, affect the tolerance of your variables clearance values are 11, 1 respectively -- bearing outer ring end face of large tolerances; 1 large end bearing inner ring outer ring end face 2 large tolerances; tolerances of bearings; 2 large end face of the inner face of tolerance between the two bearings, bearing; the small ring thickness tolerances; spacer ring tolerances; axial length tolerances; and two bearing diameter tolerances, and the corresponding axis tolerances (same axis but not at the same time processing is considered as two independent variables), consider the last four variables is because of you this application should be tightly matched with the inner ring, it will affect the clearance.

- Q: What is the size of tapered roller bearings 352214?

- Bearing type: tapered roller bearingNew model: 352214Old model: 97514EInternal diameter (mm):70Outside diameter (mm):125Width (mm):75

- Q: What are the conditions for the normal and reverse loading of tapered roller bearings?

- When the transmission parts between the two bearings, the formal wear of the pressure center to reduce the distance, and help to improve the rigidity of the shaft, the reverse is the opposite. Therefore, two contact ball bearing or tapered roller bearing suits and reverse installation should be based on the transmission parts (gear, worm) considering the structure and the axis. And choose to use.

- Q: The roller of tapered roller bearings is cylindrical or cylindrical body? Why roller drawing method of drawing section for the rectangular (here I want to add: I have seen the N version, some of the paintings is rectangular, trapezoidal and some paintings, 2 versions, a few of my book is that the proportion is A/2 the roller projection) it indicates that the real roller should be a cylinder or a cylindrical body roller is... What master?

- Cylindrical rollers are used only when the raceway is a cylinder.Mechanical drawing clearly stipulates the simplified drawing method of tapered roller bearings. Rollers are drawn into cylinders.

- Q: What items should be inspected for tapered bearings?

- 2, tapered roller bearings are not allowed to have an electric drill pattern, vibration patterns, yin and Yang face and polished traces, did not promise to emerge supporting construction and obvious measurement traces, did not agree to knock bumps and obvious color difference.3, the name of the whole machine did not promise to have oxide skin.

- Q: Tapered roller bearing: Bearing expert why burned or locked

- Shaft tolerance is relatively small and fine head, the inner shell inside and nose has obvious signs of friction. If there are traces of friction on one side or on both sides of the inner shell, there is an abnormal contact with the inner shell of the bearing and the friction of the inner shell of the bearing.2, the inner shell shell burning marks are not serious, roller black even deformation, generally is the inner shell or casing tolerance, Ambassador bearing gap smaller, and even negative tolerance caused by burning. Or in the maintenance of the bearing selection is not correct, you can use large clearance bearings.3, the shell burned seriously, the inner shell, roller are no obvious changes, you can observe whether the shell has traces of friction. There are traces of friction on the outside, and it can be considered that the tolerance between the bearing shell and the shaft is insufficient, which results in abnormal friction caused by the slipping of the housing. If there are traces of friction on one side or on both sides of the shell, there is an abnormal contact between the component relative to the bearing housing and the bearing housing, and the heat generated by friction will be burned out.

- Q: Taper roller bearings limit speed, according to what to calculate, there is no formula for what?

- First of all, different types of tapered roller bearings, the limit speed is different. Bearing on catalog.Second, the calculation of bearing limit speed is calculated by computer simulation of bearing manufacturer. It is very complicated. Mainly based on frictional heat generation and cage strength limit.So, we use bearing technology or design personnel, only need to control your speed in the following catalog bearing manufacturers can.In addition, oil lubrication is better than grease lubrication at the same speed.

- Q: The installation of tapered roller bearings

- 1, for example, a shaft needs to be fitted with two such bearings at both ends. Can it be installed in the same direction?The force of the shaft is concerned. If the shaft is indeed subjected to one-way axial force, of course, it can be installed in the same direction. If it is subjected to biaxial axial force, it will not work

- Q: The device is a vertical axis vertically arranged in the bearing chamber, the upper shaft without suspension, supported by bearings, shaft bearings are installed at the bottom of the outdoor rotating parts weighing 50 kg, the two ends of the shaft are used in single row tapered roller bearings, the bearings between the length of 30 meters. The rotation speed of the shaft is 480r/min. The device is suspended on a rotating turntable and is subjected to centrifugal force during operation...

- Why not such a large selection of axial thrust bearing, if the radial force selected contact angle greater than 45 degrees (thrust) tapered roller bearings or spherical roller bearings are good, ordinary radial cone bearing axial force mainly depends on the inner ring rib, movement and rib roller end surface contact of gyro rotation, life too effect of axial force, and excessive axial force will make rib fracture.

- Q: Turbine turbo rod reduction box, tapered roller bearing at both ends of wormGap measuring method, tapered roller bearingsThe gap is +-0.03, so how do I know the gap is in the range?.

- The utility model relates to a special measuring tool for the axial clearance of a tapered roller bearing, relating to a measuring tool used for measuring the gap between single row tapered roller bearings. Including about two relative PTFE gland set, the upper and lower ends of the gland in two PTFE is formed in the end of the notch, which formed a central notch, a notch in the center of the PTFE sleeve in the two or so is PTFE gland and PTFE sleeve are connected together by wing screw. The utility model has the advantages of greatly improving the measuring accuracy and accuracy, reducing the measuring error, and improving the maintenance efficiency and quality. It avoids the deviation in the maintenance process due to the different experience of the operator, and is simple and easy to operate.

Send your message to us

Tapered Roller Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords