Turntable Bearing Precision Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

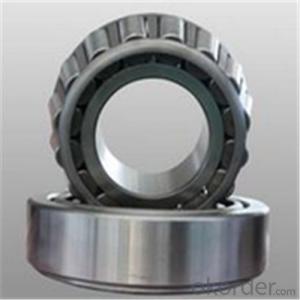

Turntable Bearing Precision

Description:

The turntable bearing is a large bearing to bear large axial load, radial load and overturning moment load bearing set, rotate transmission, fixed and other functions in a special structure. Under normal circumstances, the turntable bearing itself with the mounting holes, lubricants and seals to meet a variety of working conditions, the different needs of various types of host; the other hand, wheel bearings itself has a compact structure to guide the rotation convenient, easy to install and easy to maintain and so on, are widely used for hoisting and conveying machinery, mining machines, construction machinery, port machinery, wind power generation, medical equipment, radar and missile launchers and other large-scale rotary devices

Turntable Ring Bearing Features:

1.High load-carrying capability

2.Ability to accept the combined loads;axial ,radial and tilting moments

3.Flexibility with product design.

F&Q

Q:How long es cycle of bearing life?

A:According to international standards, at least a year and a half , up tu 2 years

Q:How to maintenance bearing

A:Add to lubricantes on time

Q:Have diagram for bearing

A:The small one no have, large bearings will provide diagram

- Q: What is the weight calculation formula for slewing bearings? Can you give me an example of this?

- The code representation of slewing bearing is made up of Dandong phase three turntable bearing manufacturing Co., Ltd. collects and provides a code name. The bearing code is composed of the basic code and the post code.

- Q: In the drilling rotary system, how is the clearance between the rotary bevel gear and the clearance of the auxiliary bearing adjusted?

- The clearance of the bevel gear can be realized by moving the bevel gear, and the clearance adjustment of the bearing can be realized by the length of the end of the shim or end cap

- Q: How to judge the replacement time of slewing bearing?

- Slewing bearing is also an important part of machinery, and plays a very important role in construction machinery. If the slewing bearing is a little damaged, it will affect the normal operation of the machine. However, the slewing bearing must be replaced after a period of time. Then, how to judge the turntable bearings how to replace it?To determine the replacement time of slewing bearing, can judge the bearing status and bearing should be decided when the repair by iron spectrometer or SPM or I-ID - 1 type bearing operating state monitoring instruments, this is the most convenient and reliable method.When using the HD - 1 type instrument, when the pointer by the warning area close to the danger zone, and take measures to improve the lubrication in the pointer does not return, it can determine the bearing itself, this advantage has not yet entered the danger zone, bearing repair.

- Q: When it rotates, it will make a strange noise. When will this sound disappear?

- This is normal! The new ones are all like this! The pressure of the turret of the excavator is different from that of other cars; the pressure is very large and can not be disappeared at one time! The other car's bearings are still new; let alone the excavator; so you don't have to worry that the sound will take off in about ten days.

- Q: After I change a new revolving mechanism, it still rattles. What's the matter? Urgently!

- First of all, add lubricating oil, if not, check the bearings are not damaged

- Q: The turntable of the excavator keeps ringing and leaking oil. When it hits butter, it does not ring on the same day and it will ring in second days

- (6) the internal seal has obvious damage: turn the gear ring, grease, check the cover, check the ring, the oil cavity, whether there is a significant reduction in oil, and whether there are broken oil seals. If there is a substantial decrease in fat, it indicates that the oil has been left out. (7) to determine the bearing cavity of the oil leakage is still the slewing ring cavity grease: different colored oils and injected into the bearing cavity, after a period of time (such as 150h) after use, such as grease bearing cavity oil has basically replaced after, according to the color of oil leakage around determine the slewing ring of oil or grease in bearing chamber. This is one of the methods used to judge whether the internal seal has failed or not. (8) to observe whether or not a normal rotary equipment: if the equipment in the rotary motion of the abnormal sound or unstable phenomenon, it may be bearing clearance is too large and uneven, resulting from the outer oil seal extrusion bearing in the rotation process of oil. (9) check the inner oil seal: the above inspection has been completed, and the elimination of problems, the problem can be concentrated in the bearing oil seal. Take out the surrounding bolts of the revolving parts, remove the tubing on the moving part, and hoist the upper frame part with a crane. Since this method requires the use of cranes and the workload of the whole process is relatively large, so this is the last step in checking and solving problems. Therefore, it is suggested that this method be adopted after all the foregoing steps have been completed and other possibilities have been eliminated. Three, treatment methods: 1, if once identified as a result of sealing problems, you need to remove the old seal, and use diesel or gasoline cleaning sealing groove, the new seal completely into the sealing groove can. It should be noted that there is a joint after sealing the ring, and it needs double tubes

- Q: Long excavator turntable has abnormal sound, bearing will be broken?

- Mechanical components will have a certain degree of wear but are engineers calculate even not placed will rust all mechanical equipment regular maintenance or replacement of parts is the best domestic why always say the quality is not good because of consumer attitudes and people make ends meet caused in fact quality is not important mainly in the maintenance and regular replacement maintenance to avoid greater losses in the process of using for reference

- Q: 500KG, 1.5M maximum diameter of the equipment is now fixed on the table, the use of turntable bearings, the cost is too high, there is no low-cost feasible way.

- In this way, the force of your situation can be completely replaced without overturning moment.

- Q: such bearings, cost-effective outer diameter of 15020030040020Domestic YRT cross roller slewing bearings, such bearings (cost-effective to high), the outer diameter of 150200300400, about how much? As a manipulator, the joint has seen a single volleyball, four point contact, I do not know how this quality, cross roller and double volleyball is more durable than that?

- 1., from the outside diameter can not determine the price, because the cross roller is also divided into several kinds, there are internal teeth, external teeth, toothless, as well as three rows of cross, so the price gap is very large,

- Q: What are the cautions for turntable bearings?

- Slewing bearing is also called slewing bearing, slewing bearing is also called slewing bearing. But there is a difference between strict points. Slewing bearing is mainly a simple turntable bearings, such as the outer ring, inner ring, steel ball, isolation block combination of turntable bearings, in fact, than slewing bearings to some advanced, specifically, you Baidu check it.

Send your message to us

Turntable Bearing Precision Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords