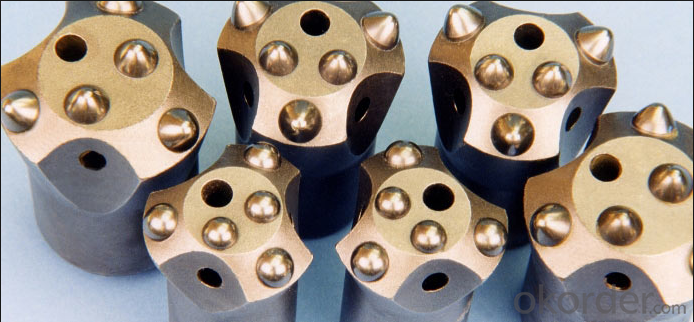

taper button bit dia 34, 36,38 from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are specialized in rock drilling tools,such as taper button bit, thread button bit, Integral drill rod, DTH bit, DTH hammer, Air leg rock drill, Excavator Mounted rock driling and splitter, expansive mortar.

Product:

Taper button bit as small hole bit is different with thread button bit as long hole bit to use taper match with bit with rod to be used for air leg or hand held jack hammer driller in quarrying, and mining. Tapered button drill bits are widely used for drilling hard or very hard work. In addition to tapered button drill bits, we provide tapered chisel drill bits, as well as taper drill rods, etc.

Description of button bit:

(1)Connect shank Size: Φ19, Φ22, Φ25 at most

(2)Bit Diameter : Diameter 32mm,34mm,36mm, 38mm,40mm

(3)Tapered connection: 6 degree, 7 degree, 11 degree, 12 degree etc.

(4)Material Alloy Steel Bar 45CrNiMoV, Tungsten Carbide Tips YK05 or T6.

(5)Button Shape Ballistic Face Type Flat Face; Bit Body Standard

(6)Qty of button: 5,7, 8 pcs

(7)main market: India, Saudi, Chile, South Africa, stone country consume too much

Specification of button bit:

Tapered button bits Diameter(mm) | No*button diameter | Flushing hole | Weight | ||||

mm | inch | Front | Gauge | Angle | Front | Side | |

32 | 1 1/4 | 1*8 | 3*8 | 35° | 1 | 1 | 0.24 |

33 | 1 19/64 | 2*7 | 5*7 | 35° | 2 | 1 | 0.26 |

34 | 1 11/32 | 2*7 | 4*7 | 40° | 1 | 1 | 0.29 |

35 | 1 3/8 | 2*7 | 5*8 | 35° | 1 | 1 | 0.33 |

36 | 1 27/64 | 1*8 | 3*9 | 40° | 1 | 1 | 0.37 |

36 | 1 27/64 | 2*7 | 5*8 | 35° | 1 | 1 | 0.37 |

38 | 1 1/2 | 1*8 | 3*9 | 35° | 1 | 1 | 0.38 |

38 | 1 1/2 | 2*7 | 5*8 | 35° | 1 | 1 | 0.38 |

38 | 1 1/2 | 2*7 | 5*9 | 40° | 2 | 1 | 0.38 |

40 | 1 37/64 | 1*8 | 3*9 | 30° | 1 | 1 | 0.40 |

40 | 1 37/64 | 1*9 | 3*10 | 30° | 1 | 1 | 0.40 |

40 | 1 37/64 | 1*9 | 3*9 | 35° | 1 | 1 | 0.40 |

40 | 1 37/64 | 2*7 | 5*9 | 35° | 1 | 1 | 0.40 |

42 | 1 21/32 | 1*8 | 3*9 | 30° | 1 | 1 | 0.43 |

42 | 1 21/32 | 1*9 | 3*10 | 30° | 1 | 1 | 0.43 |

42 | 1 21/32 | 1*9 | 3*9 | 35° | 1 | 1 | 0.43 |

42 | 1 37/64 | 2*8 | 5*9 | 35° | 1 | 1 | 0.43 |

Company Profile:

CNBM is the largest state-owned enterprise in China building material & equipment industry. Up until October of 2011, our total assets exceeded RMB 190 billion, with 130,000 employees and over 300 subordinate companies. In the year 2012, we are ranked as No. 365 in World Top 500 Enterprises by Fortune, and No. 2 in global building materials industry, second only to Saint-Gobain.

FAQ:

1. Q: Can I get some samples?

A: We are honored to offer you samples for quality check.

2. Q: Do you have the products in stock?

A : Yes , We have sample for several models now could supply to you.

3. Q: What’s the delivery time?

A: It usually takes about 25 days to produce an order. But the exact delivery time might be different for different orders or at different time.

4. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. Rock drilling tools workers always attach great importance to quality control from the every beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

6. Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. Our company is world top 500, that is the biggest supplier and manufacture in China, having a good reputation around the world.

7. Q: What's the payment you accept ?

A: As usual our payment is T/T, other payment can consider.

As the largest manufacturer and exporter of building materials in China, we avail ourselves of this opportunity to approach you for mutual-beneficial cooperation. If you want to know more, pls contact me freely.

- Q: Types of impact drills

- There are two types of drill hole two groove round handle (usually produced abroad and anti hammer production abroad is used), four hole square shank (general domestic production of electric hammer used) and five bit six bit long pit, angle etc.. Hope to be of help to you.

- Q: What drills are used in stainless steel drilling?

- Stainless steel cutting drill martensitic stainless steel 2Crl3, just wear E-E chipbreaker; while drilling of lCrl8Ni9Ti austenitic stainless steel, but also need additional A-A chipbreaker.The characteristics of S type carbide drill is: chisel edge can reduce the axial force of 50%; a former angle is positive, sharp edge; web thickness increases, increase the drill rigidity; two jet cutting fluid hole; arc cutting edge and the chip distribution is reasonable, easy cutting into pieces. In order to facilitate discharge.The characteristics of transposition of cemented carbide drill for shallow holes is equipped with two front end of the drill bit is asymmetric convex triangular blades, different parts of the chip removal hole, automatic centering, straight hole, and the cutting length is short; blade rake face is provided with a plurality of pit groove cutting, good performance especially reliable chip breaking, the chip is consistent with the broken chip cooling; the cutting fluid is directly sprayed to drilling surface, improve the cooling effect, chip very smooth; especially according to the hard alloy blade with different grades of workpiece materials, cutting speed is 80 ~ 120m/min, drilling is very brisk.

- Q: Tap with 5 taps. How many drills are drilled?

- Calculation formula:The workpiece is a brittle material (cast iron, bronze, etc.): the bore diameter is D=d- (1.04 to 1.08) tThe workpiece is made of plastic material (steel, copper, etc.): bore diameter is D=d-tD: nominal diameter of thread, t: pitch, unit: mm

- Q: What is the difference between steel and high-speed steel?

- Tungsten is a kind of high speed steel was non alloy steel containing tungsten before, now use less, there are people on the use of power tools. Before the steel generally used for ordinary tool making hand taps, drills, saws and cutting speed is relatively low, the hardness is about 60~63HRC. High speed tool steel is now divided into low alloy, high performance and other types, widely used in the manufacture of various cutting tools.

- Q: What bits of percussion drills are made of?

- Features: with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.

- Q: What size drills and taps are required for drilling M10's internal threads?

- M10*1.5 (not considering tap tap for precision thread); if M10*1.25, with Phi 8.7 bit; M10*1.25 (without considering precision tap tap thread); if it is M10*1, with 9 bit;

- Q: What drill is used for punching aluminum parts?

- Aluminum alloy, copper, stainless steel, these materials are not high hardness, aluminum alloy, copper soft, frequent drilling process, it is easy to have cutting, there will be a lot of burrs, aluminum alloy special drill.

- Q: What kind of steel do you need to drill?!

- Some use ion implantation technology to inject titanium, nitrogen and carbon into the substrate at a certain depth, which not only improves the hardness and strength, but also makes them move when the drill is regrinding. Also, a diamond film is formed at the top of the drill bit by physical means, which greatly improves the hardness and wear resistance of the drill bit. The hardness and strength of cemented carbide are not only related to the ratio of tungsten carbide to cobalt, but also to the particle of powder.

- Q: An expansion screw with a diameter of 20. How much impact bit do you need to use?

- The table above is the reference value of the match;2, the specific adaptation, also need to be flexible according to the actual situation, if the fixed place expansion screw is loose, need to be reduced if the fixed impact drill specifications; expansion screws tight place, according to the above table match.

- Q: M2.5 hit the bottom teeth with much bit

- Then, the chip 2.5-0.45=2.05 is used to tap bottom drill bit drilling. If it is an extrusion tap, the formula is 2.5-0.45/2=2.275's drill.

Send your message to us

taper button bit dia 34, 36,38 from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords