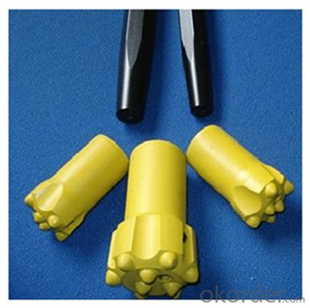

Top Hammer taper button bit dia34mm hot selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are specialized in rock drilling tools,such as taper button bit, thread button bit, Integral drill rod, DTH bit, DTH hammer, Air leg rock drill, Excavator Mounted rock drilling and splitter, expansive mortar.

Product:

Taper button bit as small hole bit is different with thread button bit as long hole bit to use taper match with bit with rod to be used for air leg or hand held jack hammer driller in quarrying, and mining. Tapered button drill bits are widely used for drilling hard or very hard work. In addition to tapered button drill bits, we provide tapered chisel drill bits, as well as taper drill rods, etc.

Description of button bit:

(1)Connect shank Size: Φ19, Φ22, Φ25 at most

(2)Bit Diameter : Diameter 32mm,34mm,36mm, 38mm,40mm

(3)Tapered connection: 6 degree, 7 degree, 11 degree, 12 degree etc.

(4)Material Alloy Steel Bar 45CrNiMoV, Tungsten Carbide Tips YK05 or T6.

(5)Button Shape Ballistic Face Type Flat Face; Bit Body Standard

(6)Qty of button: 5,7, 8 pcs

(7)main market: India, Saudi, Chile, South Africa, stone country consume too much

Specification of button bit:

Tapered button bits Diameter(mm) | No*button diameter | Flushing hole | Weight | ||||

mm | inch | Front | Gauge | Angle | Front | Side | |

32 | 1 1/4 | 1*8 | 3*8 | 35° | 1 | 1 | 0.24 |

33 | 1 19/64 | 2*7 | 5*7 | 35° | 2 | 1 | 0.26 |

34 | 1 11/32 | 2*7 | 4*7 | 40° | 1 | 1 | 0.29 |

35 | 1 3/8 | 2*7 | 5*8 | 35° | 1 | 1 | 0.33 |

36 | 1 27/64 | 1*8 | 3*9 | 40° | 1 | 1 | 0.37 |

36 | 1 27/64 | 2*7 | 5*8 | 35° | 1 | 1 | 0.37 |

38 | 1 1/2 | 1*8 | 3*9 | 35° | 1 | 1 | 0.38 |

38 | 1 1/2 | 2*7 | 5*8 | 35° | 1 | 1 | 0.38 |

38 | 1 1/2 | 2*7 | 5*9 | 40° | 2 | 1 | 0.38 |

40 | 1 37/64 | 1*8 | 3*9 | 30° | 1 | 1 | 0.40 |

40 | 1 37/64 | 1*9 | 3*10 | 30° | 1 | 1 | 0.40 |

40 | 1 37/64 | 1*9 | 3*9 | 35° | 1 | 1 | 0.40 |

40 | 1 37/64 | 2*7 | 5*9 | 35° | 1 | 1 | 0.40 |

42 | 1 21/32 | 1*8 | 3*9 | 30° | 1 | 1 | 0.43 |

42 | 1 21/32 | 1*9 | 3*10 | 30° | 1 | 1 | 0.43 |

42 | 1 21/32 | 1*9 | 3*9 | 35° | 1 | 1 | 0.43 |

42 | 1 37/64 | 2*8 | 5*9 | 35° | 1 | 1 | 0.43 |

Company Profile:

CNBM is the largest state-owned enterprise in China building material & equipment industry. Up until October of 2011, our total assets exceeded RMB 190 billion, with 130,000 employees and over 300 subordinate companies. In the year 2012, we are ranked as No. 365 in World Top 500 Enterprises by Fortune, and No. 2 in global building materials industry, second only to Saint-Gobain.

FAQ:

1. Q: Can I get some samples?

A: We are honored to offer you samples for quality check.

2. Q: Do you have the products in stock?

A : Yes , We have sample for several models now could supply to you.

3. Q: What’s the delivery time?

A: It usually takes about 25 days to produce an order. But the exact delivery time might be different for different orders or at different time.

4. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. Rock drilling tools workers always attach great importance to quality control from the every beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

6. Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. Our company is world top 500, that is the biggest supplier and manufacture in China, having a good reputation around the world.

7. Q: What's the payment you accept ?

A: As usual our payment is T/T, other payment can consider.

As the largest manufacturer and exporter of building materials in China, we avail ourselves of this opportunity to approach you for mutual-beneficial cooperation. If you want to know more, pls contact me.

- Q: How do you drill a bit?

- A bit, including a cutter rod, a cutter rod tip, tip two is located in a main plane (C - C) on the cutting insert (5, 5 '), the cutting blades (5, 5') have in common second planes (E - E). The orientation of the short cutting edge center. The blade forms a point like center, the cutting edge is used to enter the workpiece, and thereby the bit is aligned. Two chip grooves (6, 6 ') are arranged on the cutter bar, and the chip removing slots (6, 6') extend from the tip to the end. In any section along the bar, the flutes are located are diametrically opposed to each other's position in the flat tube, flat tube and two common edge edge in the pipe on both sides of the belt plane (F F) 90 degrees extension, wherein the knife rod has a maximum in the rigid plane. The orientation of the second plane (E E) of the center cutting edge is approximately 90 degrees with respect to the main rigid direction (F F) of the blade plane or the bottom of the cutter bar.

- Q: 1 inches of steel plate, what drill can drill through?

- Mainly used in drilling machines, lathes, flashlights and other mechanical equipment for the processing of different diameter aperture. Generally speaking, twist drills are straight shank and taper shank twist drills. Straight shank drill: suitable for drilling diameter psi below 13.0mm small diameter, taper shank twist drill for aperture and torque big hole.

- Q: What drill is drilled on marble?

- Do not use impact drilling, use an electric drill, and a high-speed steel drill, which is equivalent to grinding a hole in the marble!

- Q: How do you determine the speed of the drill? Is there any standard?

- Large hole processing speed is not too fast, too fast, easy to make the head color (coke), resulting in turn annealing, eventually scrapped;Small rotor speed should be fast forward to the amount of slow, fast, easy to break, turn around, pay attention to crumbs.

- Q: The installation method of the electric hammer drill

- The installation method of the electric hammer drill:When installed, the drill chuck hammer directly inserted, can rotate around until the drill bit is automatic locking, finally pulling the drill bit to determine whether it is locked correctly.

- Q: What kind of drills are commonly used in CNC machining centers?

- Shallow hole drilling: in the processing center use, usually will use indexable shallow hole drilling, that is, with the alloy blade of the drill bit, use this kind of drill, generally require the machine spindle has internal cooling device, otherwise it will reduce processing efficiency.Deep hole drilling: as its name suggests, it is a drill bit used to process deep holes. Its diameter and length are relatively large. Generally, there are 2 guide blades on the side edge.Center drill: used to prevent hole change during drilling and to use when locating holes.Centering bit: a better positioning capability than an ordinary bit, usually used for centering holes or for machining thin plates. The difference between a drill and an ordinary drill is that the method of grinding is different.Drill: drilling reaming drill to drill, no vertex, generally between 0.5-2MM for reaming, reamer used with.

- Q: Drill bit specifications

- No, because the diamond drill bit and drill, impact drill bit ordinary regardless of specifications, size and shape are inconsistent, on the one hand can not install the clamping key is no guarantee of safety and accuracy.

- Q: The difference between left and right drills used to drill holes

- If the twist drill is said to be left-handed or right-handed, this is related to the direction of rotation of the spindle. Regular drilling machines use the right-hand bit; in some special cases, the main axis of the drilling machine rotates opposite, and the left-hand drill is required.

- Q: Why not hammer drill iron

- Electric hammer drill (electric hammer drill), is the "two function drill" and "hammer" handheld electric tool, "rotary cutting drill", with the impact of the impact mechanism of driving impact drill bit, drill driven in rotation at the same time, there is a direction perpendicular to the rotation of the rotary drill the reciprocating motion of the hammer. For concrete, brick, tile, marble and other materials drilling. "Hammer" to drive the impact force of drill rod, used for concrete, bricks and other materials on the slotting, holes or broken concrete etc..

- Q: What drill is drilled after quenching?

- Carbide coated tools can handle around HRC50 of materials, such as Mount Vickers 840, and material 1220

Send your message to us

Top Hammer taper button bit dia34mm hot selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches