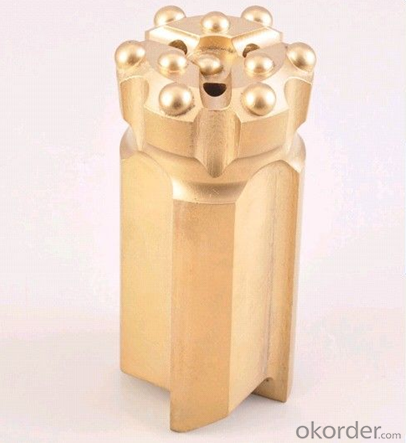

thread button bit from China dia 35-45mm R22

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are specialized in rock drilling tools,such as taper button bit, thread button bit, Integral drill rod, DTH bit, DTH hammer, Air leg rock drill, Excavator Mounted rock driling and splitter, expansive mortar.

Product:

Thread Button Bits: High quality and several thread with various carbide tips like YK05 are available. All products can be developed upon customers' request. Premium designs and steel and premium tungsten carbide insert grade T6 supplied by Boart Long year, Offers industry-leading strength and penetration rates for more productivity, Excellent straightness and hole clean quality, Get max. drilling performance for rock drills with long life to save up fuel cost rate.

Description of button bit:

Our company supply all kind of button bits with Rope thread

R32-43MM, R32-45MM, R32-51, R32-64, R32-76;

T38-64, T38-76MM, T38-89, T38-102MM;

T45-76MM, T45-89MM, T45-102MM;

T51-89MM, T51-102MM, T51-127MM etc.

all face design, flat face, drop-center face, normal body and retrac body.more

Specification of button bit:

Thread | Diameter range | Skirt Design | Face Design | Button Design |

R22 | 35 – 45mm | Normal | Flat Face | Hemispherical |

R25 | 33 – 57mm | Normal | Flat Face | Hemispherical |

R28 | 36 – 51mm | Normal | Flat Face | Hemispherical |

R32 | 41 – 89mm | Normal | Flat Face | Hemispherical |

R35 | 48 – 51mm | Normal | Flat Face | Hemispherical |

R38 | 64 – 102mm | Normal | Flat Face | Hemispherical |

T38 | 57 – 102mm | Normal | Flat Face | Hemispherical |

T45 | 70 – 127mm | Normal | Flat Face | Hemispherical |

T51 | 76 – 140mm | Normal | Flat Face | Hemispherical |

T60 | 89 – 140mm | Normal | Flat Face | Hemispherical |

ST58 | 89 – 140mm | Normal | Flat Face | Hemispherical |

GT60 | 93 – 140mm | Normal | Flat Face | Hemispherical |

ST68 | 102 – 152mm | Normal | Flat Face | Hemispherical |

Company Profile:

CNBM is the largest state-owned enterprise in China building material & equipment industry. Up until October of 2011, our total assets exceeded RMB 190 billion, with 130,000 employees and over 300 subordinate companies. In the year 2012, we are ranked as No. 365 in World Top 500 Enterprises by Fortune, and No. 2 in global building materials industry, second only to Saint-Gobain.

FAQ:

1. Q: Can I get some samples?

A: We are honored to offer you samples for quality check.

2. Q: Do you have the products in stock?

A : Yes , We have sample for several models now could supply to you.

3. Q: What’s the delivery time?

A: It usually takes about 25 days to produce an order. But the exact delivery time might be different for different orders or at different time.

4. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. Rock drilling tools workers always attach great importance to quality control from the every beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

6. Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. Our company is world top 500, that is the biggest supplier and manufacture in China, having a good reputation around the world.

7. Q: What's the payment you accept ?

A: As usual our payment is T/T, other payment can consider.

As the largest manufacturer and exporter of building materials in China, we avail ourselves of this opportunity to approach you for mutual-beneficial cooperation. If you want to know more, pls contact me freely.

- Q: Can twist drills drill through wall tiles?

- To use the electric drill tile or impact drill with drill, drill bit to use glass with water, careful operation, drilling speed from slow growing fast.

- Q: Types of impact drills

- There are two kinds of percussion bit, one is double groove, the other is square.

- Q: What drill holes are used to break the screw?

- The metal, its principle is to discharge at the moment, a sharp change of arc temperature and with pressure, so that the metal material of the point immediately melted, gasification, splashed liquid and explosive, condensed into solid particles is the working fluid. At this time, the metal surface is etched into a pit, so EDM can be easily processed on any metal workpiece, so it is convenient and quick.

- Q: How do you get yellow on the surface of the drill bit?

- Coated cutting tools are in hard alloy high strength and toughness or high speed steel (HSS) on the body surface by vapor deposition method is coated with a thin layer of good abrasion resistance of refractory metal or non metal compounds (can also be applied in ceramics, superhard materials such as diamond and cubic boron nitride blade) obtained. The coating acts as a chemical barrier and thermal barrier, reducing the diffusion and chemical reaction between the tool and the workpiece, thereby reducing the wear of the crescent groove.

- Q: With what drilling steel

- Tungsten steel (hard alloy) with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.

- Q: To do the M4 screw hole, what size holes must be drilled first?

- According to my experience in the industry, since you are an aluminum piece, you should use kerosene or kerosene and cutting fluid when you tap. This will make the tapping more smooth and protect the tap and thread. In addition, the general aluminum pieces should be steel wire screw, otherwise, the teeth are easily broken.

- Q: What does the cutting depth of the drill mean 3D?

- For example, 3D, the drill diameter is 20MM, then the effective drilling depth is 60MM, but the actual standard bit slot length must be about 80mm, because we should consider the chip space!!

- Q: Construction drills, woodworking drills, high-speed steel drills, shapes and uses, what's the difference?

- A construction bit, a carpenter's drill, has the same diameter as a shank and is longer than a bit of a high-speed steel.High speed steel drill stem generally 3.175mm diameter, see need, more than 6.5mm rarely.The drill bits in 3 are of different materials

- Q: Specification of plastic expansion plug and collocation of drill bits

- A plastic expansion tube has a certain expansion. Also ensure that the initial plug is inserted, and the bore diameter is the same as or slightly larger than the nominal diameter.

- Q: What kind of drilling bit is good for stainless steel?

- With high cobalt drill can, if drilling is much, your point is not a problem, the key is durable, waste less. To choose according to the size of your drill bit.

Send your message to us

thread button bit from China dia 35-45mm R22

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords