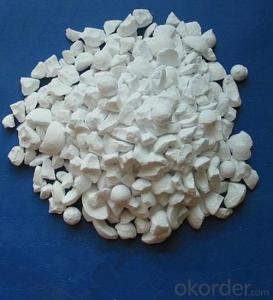

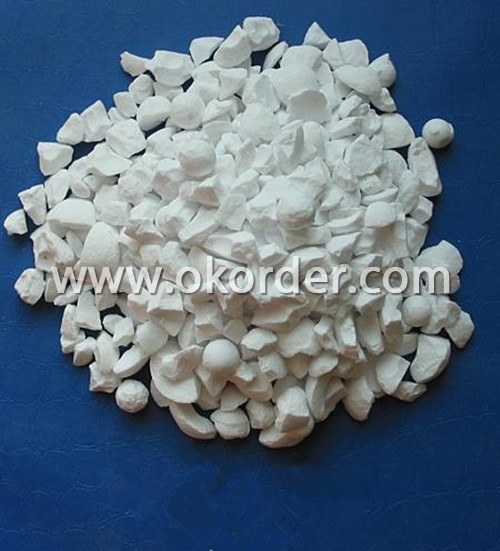

Tabular Alumina Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Tabular Alumina:

Super high temperature shaft kiln sintered plate corundum that takes alumina as raw material is molded by milling and drying;

on condition of quick warming and cooling in super high temperature shaft kiln, it becomes lots of tight column crystal and

the dimension of crystal is among 30-200um; there are lots of alumina corundum that has high purity with lots of closed micro-holes.

Specification of Tabular Alumina:

|

Item |

SYA-99 | ||

|

Grain size (mm) |

Standard |

Typical | |

|

Apparent porosity (%) |

≥3.00 |

≤5.0 |

3.5 |

|

1.00~3.00 |

≤7.0 |

5.5 | |

|

Volume density (g/cm3) |

≥3.00 |

≥3.50 |

3.53 |

|

1.00~3.00 |

≥3.45 |

3.48 | |

|

Al2O3 (%) |

≥99.00 |

99.4 | |

|

NaO2 (%) |

≤0.40 |

0.30 | |

Application of Tabular Alumina:

It is one kind of excellent insulation raw materials for fire-proof, porcelain and electric instruments;

it is also excellent material for milling tool and polishing milling.

Advantages:

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q: Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will be completely liquefied in the furnace of about 1100 degrees for half an hour and will not deform below 600 degrees. toughened glass fire-resistant glass is the product of ordinary glass after being processed Glass will mainly burst after encountering fire. When unevenly heated or encountering sudden drastic changes in temperature, ordinary glass will burst if the sharp temperature difference is over 70-120 degrees and toughened glass will burst at 200 degrees. It is not yet clear of the bursting temperature for the refractory glass. If the overall glass is not heated evenly, it will have no significant change below 600 degrees, and it will deform with the increase of temperature until melting. The fire-resistant time of the glass you said is the time to heat the glass into the extreme temperature differences it can endure, which should not be more than 10 minutes

- Q: How long usually will the A-level fireproof materials prevent the flame?

- A-level fireproof materials refer to the materials which are made of non-combustible materials, it is a different concept from fire resistance. non-combustible elements: Components are made of non-combustible materials. Non-combustible materials refer to materials that will not burst into flame, and burn as well as be carbonized when affected by fire and high temperature in the air. Fire resistance: Having a fire resistance test on any building components -----according to the standard time-temperature curve. This period starts from the time when affected by fire and ends up with losing the ability to support or to insulate fire or the integrity of the components. It can be expressed in hours.

- Q: What is the material composition of the new fire-resistant coating?

- The basic composition of thick coating steel structure fire is: Binder (Portland cement, magnesium oxychloride or inorganic high-temperature bonding agent), aggregate (expanded vermiculite, perlite, aluminum silicate fiber, mineral wool, rock wool, etc.), chemical additives (modifiers , hardening agent, waterproofing agent) and water. Fireproof coating binders Portland cement, magnesium oxychloride cement and an inorganic binder of the fire-resistant coating for steel structure base material. The conventional inorganic binder include alkali metal silicates and phosphates substances.

- Q: What are fireproofing materials?

- 1. Fire-resistant coatings like finishing fire retardant paint, fire retardant coating member and fire-resistant coating for steel structure; 2. Fireproofing materials of flame-retardant plastics and plastic products, textiles, flame retardant fabrics, building materials and products, flooring materials, and wall insulation system; 3. Fireproof element of fireproof panels, fire doors, fire resistant window frames, fire resistant shutter, fire-resistant glass, elevator landing doors, ventilation ducts, fire-proof?sealing?materials, and fire protection smoke exhaust fans.

- Q: What are fire?ratings of wall thermal insulation material?

- Grade A material has no ignition and is material with thermal insulation effect, anti-combustion material. Currently it mainly refers to inorganic thermal insulation mortars of vitrified micro bead, hole-closed?expanded perlite, rock wool,mineral wool,glass wool,cement base or gypsum base, inorganic thermal insulation mortars and self thermal insulation system of lightweight block. Grade B1 is nonflammable thermal insulation material, which is determined by fire endurance of this material. In addition, the division of the material of different parts is different! What is commonly seen, such as EPS / XPS insulation boards adding flame retardant through special treatment. Grade B2 is combustible thermal insulation materials, and what is commonly seen is EPS expanding polystyrene board and XPS extruded polystyrene board, that is, the general board. This material has low ignition point, and releases large amounts of harmful gases in the combustion process . Grade B3 is flammable insulation material. Thermal insulation material with polyphenyl foam as main material is commonly seen. Since this material is highly flammable, it has been eliminated external wall thermal insulation materials.

- Q: What does refractory mean?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: which is better as household fireproof material ?

- the thickness recommended is 1mm or more # 304 stainless steel plate, refractory corrosion-resistant, easy to clean. It now appears that among the most common fireproof material, asbestos is the best. But the asbestos harmful effect is also great, especially for lung damage. Now on the market, the polyurethane, polystyrene, rock wool glass wool, phephenolic aldehyde fireproofingthermal insulation board. But now the phenolic aldehyde fireproofing thermal insulation board has superior performance! phenolic aldehyde containing only carbon, hydrogen and oxygen atoms, when subjected to pyrolysis, except small amounts of CO gas, the other will not produce toxic gases, maximum smoke density is 5.0%.

- Q: Does the aluminum silicate thermal insulation material fireproof?

- With stable performance,long fiber length, strong tensile strength, strong seismic performance, low shot, light unit weight, low thermal conductivity, good insulation properties. it is not bad.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Tabular Alumina Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords