Table Formwork System with High Quality and Stable Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 4000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

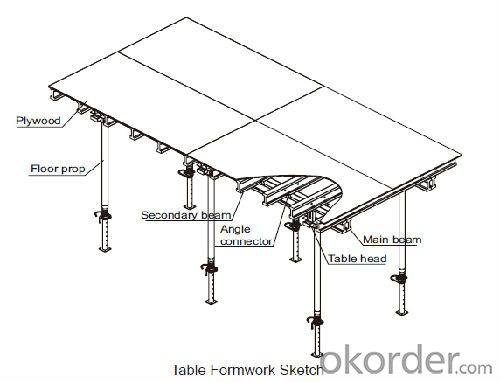

1. Structure of Table Formwork Description

Table formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost. Tie-yoke and tie-rod are used to reinforce the corner. Timber beam formwork is a highly efficient and convenient system for medium area slab project. They can be transported to next position as whole table units whether by trolley or by crane lift.

2. Main Features of Table Formwork

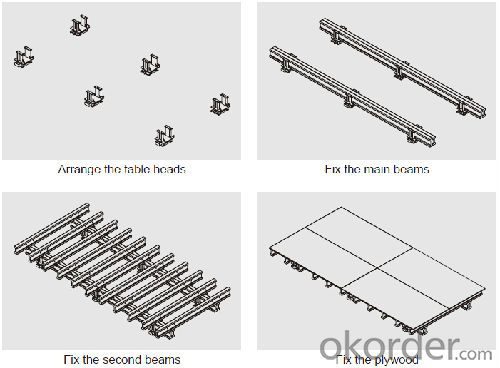

· Extension staffs at the top and bottom of the table forms

· Can adapt to most slab and beam configurations

· Modular design simplifies assembly

· The most versatile truss system available

· Reduces construction cycle times

· No nails needed, no small parts loss, and suitable for any structures

3. Table Formwork Images

4. Table Formwork Specifications

Vertical shifting of table formwork is considered simplified on site with the help of Transport fork by crane.

An optimum position of the table gravity point can be achieved by selecting the correct suspension points for the crane ropes and testing it on site by trail lifts.

The shifting trolley enables you to lower the table from the floor slightly and transport the table horizontally to the next location easily.

5. FAQ of Table Formwork

1) What can we do for you?

We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

2) What promises can be done by us?

If interested in this kind of formwork, please feel free to write us for any QUOTE.

If need any technical and building assistance, we could provide on-site professional staff for instruction.

- Q: What is the use of building wall formwork support? Thank you

- To build a scaffold to form a bracket supported by steel or wood, and with steel formwork concrete construction.

- Q: Technical specification for construction formwork safety JGJ162-2008 who has made me please

- This specification is applicable to the design, manufacture, installation and dismantling of the cast-in-place concrete engineering formwork system in construction.

- Q: 1, JGJ162-2008 construction formwork safety technical specification;2, JGJ130-2011 construction fastener type steel pipe scaffolding safety technical specifications; the friend has. Send me thanks

- 3 2.1.12 flying die flying shuttering mainly by the platform board, support system (including beam, support, support, legs, etc.) and other accessories (such as lifting and walking mechanism, etc.). The utility model is a large tool type template, which is called a table mould or a table model because of the appearance of the utility model. Because it can take advantage of lifting machinery, pouring from the well under the floor of the lift out of the transfer to the upper layer of repeated use, so called flying mode. 2.1.13 tunnel mode tunnel shuttering a combination of stereotypes template, while pouring concrete wall and floor of the template, because the shape of the template like a tunnel, it is known as the tunnel model.

- Q: 86335 template support, what is the concept of those advantages

- In the case of the construction industry, after 20 years of this industry, dedicated to technical analysis and improvement. After painstaking research, invited the domestic industry elite Magi to discuss, repeated demonstration, combined with the actual measurement through the practice of technical staff, spend long time hard work. Finally invented this new type of digital steel template support combination structure, so far spent ten years of painstaking research on the huge sums of money technology finally succeeded. To fill the gaps at home and abroad (with our understanding of the current international and domestic architectural template combination structure has not been any new structure), and won the national invention patent.

- Q: Since the building, and I would like to ask some of the basic knowledge to the construction of a unified drawing, plus or minus 0 and the height of the drawings, the roof slope requirements. Now the blue steel reinforced concrete inclined roof beams or do. Here we use multiple beams, and the waterproof, thermal insulation, in tile. Anyway, many shortcomings is wood, attic space basically scrapped, there is a fire started...I would also like to use concrete flat top, that is, do not let, more depressed.If I can use wooden beams, waterproof SBS, hanging plastic extruded board?The construction of plastic extruded board in inclined roof beams hung strong? Construction is not difficult?As well as the 8X11 meters of the roof, 30 degrees slope, sloping roof concrete cost about? I feel modeling and cloth reinforcement are very troublesome, expensive cost estimation

- Suggest that you chose to do it according to the roof beams, concrete inclined roof more difficult to operate, workers are not professional if vibration is not so dense, it is easy to Water Leakage.If you really want to use the concrete will have to change the roof to flat roof, since the construction of the team is easy to build, more secure.Cast in place concrete roof generally according to 12CM~15CM.

- Q: What is the building template support

- In the construction for concrete cast-in-place construction formwork supporting structure, widely used in steel or timber beams assembled into the template bracket, built into the scaffold to form a bracket supported by steel or wood, and with steel formwork concrete construction.

Send your message to us

Table Formwork System with High Quality and Stable Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 4000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords