Sustainable Packaging Tape:High Quality Acrylic Adhesive OPP Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: BOPP film

Adhesive Side: Single Sided

Adhesive: Water Based Acrylic

Use: Carton Sealing and Packing,Light Duty Packing,Bounding,Holding and other office and household use

Design Printing: Offer Printing

Place of Origin: China (Mainland)

Model Number: High Quality Colorful Printing Opp Adhesive Packing Tapes

Color: Clear, Tan, Yellowish, Brown, Yellow, White, Black, Blue, Green, Red etc.

Standard Size: 48mm x 66m, 50mm x 50m, 1.28m x 4000m, etc

Product Discription

Applications

Economical for general carton sealing

Auto-packing machine

Gift Wrapping & Decoration

Bundling &Strapping

Meet all kinds of transportation convenientl

Advantages:

OPP tape, superb tack and adhesion to surface

Strong grip that is ensured because of an excellent adhesive backing

Quality processing equipment that guarantees consistent quality

Peak performance even under extereme conditions of pressure and temperature

Sticks on all types of surfaces (paper, plastic, wood, glass, fiber and metal)

Consistent quality

On time delivery

Effective and timely communication

- Q: Is packaging tape safe to use on plastic picture frames?

- Yes, packaging tape is generally safe to use on plastic picture frames. It provides a secure and temporary hold without causing damage to the frame's surface. However, it is important to remove the tape carefully to avoid peeling off any paint or finish.

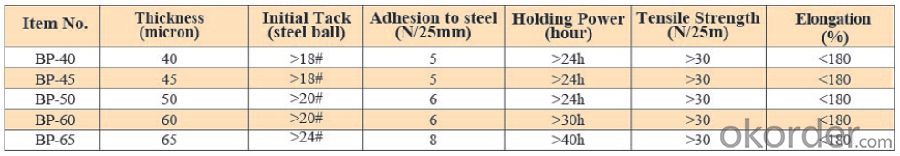

- Q: Does packaging tape come in different thicknesses for added durability?

- Packaging tape indeed comes in various thicknesses to enhance its durability. The thickness of packaging tape is measured in mils, indicating its thickness in thousandths of an inch. Packaging tape typically ranges from 1.6 mils to 3.1 mils in thickness. Opting for thicker tape generally guarantees enhanced durability and the ability to withstand heavy-duty tasks. Thicker tapes are perfect for securing large or heavy packages, as they provide superior strength and resistance against tearing. Conversely, thinner tapes may be more suitable for lighter items or less demanding packaging needs. Consequently, the availability of different thicknesses in packaging tape empowers users to select the most suitable tape that meets their specific durability requirements.

- Q: Can packaging tape be used for sealing perishable food items?

- Using packaging tape to seal perishable food items is not recommended. This is because packaging tape is typically made of materials like polypropylene or PVC, which are not suitable for food safety and may contaminate the food. Additionally, packaging tape is not designed to create an airtight seal, which is essential for preserving the freshness and preventing spoilage of perishable food items. To ensure the safety and quality of perishable food items, it is advisable to use appropriate food-safe sealing methods such as ziplock bags, airtight containers, or food-grade cling wrap.

- Q: Is packaging tape safe for use on delicate surfaces or materials?

- Packaging tape, in general, is not specifically designed for use on delicate surfaces or materials. While it may adhere well to most surfaces, it can potentially cause damage or leave residue on delicate materials such as paper, fabrics, or certain types of paint. To ensure the safety of delicate surfaces or materials, it is advisable to use specialized tapes designed explicitly for delicate applications. These tapes are often referred to as "delicate surface tapes" or "low-tack tapes." They are designed to have a gentle adhesive that can securely hold items together without causing any damage or leaving adhesive residue. Delicate surface tapes are commonly used in the arts and crafts industry, for delicate papers, scrapbooking, or as temporary adhesives for mounting artwork. They are also useful for securing lightweight or fragile items during shipping or packaging. Therefore, while packaging tape can be effective for general purposes, it is not recommended for use on delicate surfaces or materials. It is important to use the appropriate tape for the specific application to protect delicate surfaces and prevent any potential damage or residue.

- Q: Does packaging tape come in different finishes or textures for aesthetic purposes?

- Yes, packaging tape does come in different finishes or textures for aesthetic purposes. While the primary function of packaging tape is to securely seal boxes and packages, manufacturers have recognized the importance of aesthetics in packaging. As a result, they have developed packaging tapes with various finishes and textures to meet different aesthetic preferences. Some packaging tapes come in glossy finishes, which can give a more polished and professional look to the package. These tapes often have a smooth and shiny surface that reflects light, making the package appear more visually appealing. Glossy packaging tapes are commonly used in industries that require a high-end presentation, such as luxury goods or high-quality products. On the other hand, there are also packaging tapes with matte or satin finishes. These tapes have a more subtle and refined appearance, providing a sophisticated look to the package. Matte or satin tapes are often favored in industries that value a more subtle and understated aesthetic, such as cosmetics or boutique products. Apart from finishes, packaging tape can also come in different textures. For example, some tapes have a textured or patterned surface, which adds a tactile element to the packaging. These tapes can have embossed patterns, such as dots, stripes, or even company logos, which can enhance the overall visual appeal and uniqueness of the package. In summary, packaging tape does come in different finishes or textures for aesthetic purposes. Whether it is a glossy, matte, satin, or textured surface, these variations allow businesses to choose packaging tape that aligns with their branding and desired presentation. By utilizing different finishes and textures, packaging tape can not only serve its primary function but also contribute to a more visually appealing and customized packaging experience.

- Q: Can packaging tape be printed with custom logos or designs?

- Yes, packaging tape can be printed with custom logos or designs. Many companies offer the option to customize packaging tape with your own logo, text, or design. This allows businesses to create a unique and professional look for their packages, helping to enhance their brand image and make their packages stand out. Custom printed packaging tape is a great way to promote your company and create a cohesive and branded packaging experience for your customers.

- Q: Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Indeed, one can utilize packaging tape for the purpose of sealing packages containing delicate artwork or sculptures. Nevertheless, it is crucial to exercise caution in selecting the appropriate variant of packaging tape to guarantee the safeguarding of the artwork. In general, it is highly recommended to opt for a top-notch, robust packaging tape that has been explicitly crafted for the purpose of shipping and handling fragile or delicate items. These varieties of tape often possess added reinforcement through the inclusion of fibers or augmented adhesive strength, thereby ensuring a secure seal and averting any potential harm during transportation. Furthermore, it is advisable to employ suitable cushioning materials such as bubble wrap or foam padding to provide adequate protection for the artwork housed within the package.

- Q: I want to be involved in the tape industry, is the parent type their split, but do not know the parent roll cut in segmentation machine is good, or even after the parent roll processing, and also is the problem of the equipment, how much money, thank you

- Buy mother volume back, after four machines processed into finished products can be, the equipment price is: 40 thousand, -4.3 million.

- Q: How wide is standard packaging tape?

- The usual width of standard packaging tape is around 2 inches.

- Q: How do I prevent packaging tape from becoming too loose?

- To prevent packaging tape from becoming too loose, here are a few tips: 1. Use quality packaging tape: Invest in good quality packaging tape that has a strong adhesive. Low-quality tapes tend to lose their stickiness quickly, leading to loose packaging. 2. Clean and dry surfaces: Before applying the tape, ensure that the surfaces are clean and dry. Dust, moisture, or oil can weaken the adhesive, causing the tape to become loose. 3. Apply firm pressure: When sealing a package, apply firm pressure while pressing the tape onto the surface. Make sure to run your hand or a flat object along the length of the tape to ensure proper adhesion. 4. Overlap the tape: Instead of just placing a single strip of tape, overlap it by a few inches. This overlap provides extra strength and reduces the chances of the tape becoming loose. 5. Avoid extreme temperature changes: Extreme temperature changes can affect the adhesive properties of packaging tape. Avoid storing packages in areas with high humidity or extreme temperature variations, as this can cause the tape to loosen. 6. Reinforce with additional tape: If you are sealing a heavy or bulky package, consider reinforcing it with additional tape. Apply extra strips of tape across the sides or diagonally to provide extra support and reduce the risk of the tape coming loose. 7. Store packages properly: When storing packages, ensure they are stacked properly and not subjected to excessive pressure or weight. Poor storage conditions can cause the tape to loosen over time. By following these tips, you can prevent packaging tape from becoming too loose, ensuring that your packages remain securely sealed during transit or storage.

Send your message to us

Sustainable Packaging Tape:High Quality Acrylic Adhesive OPP Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords