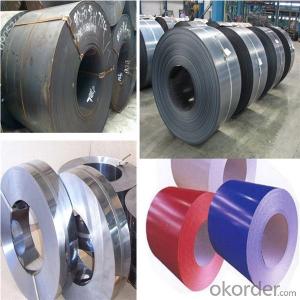

sus 304 stainless steel coil roll stainless steel price per kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard: ASTM, AISI, DIN, EN, GB, JIS

- Model Number: SUS 201 304 316 430

Type: Welded

Steel Grade: 300 Series, TP304

Application: Decorations, constructions,Heat Interchangers and heaters,etc.

Certification: BV

Welding Line Type: ERW

Thickness: 0.25--5.0mm

Outer Diameter: 10*10mm----100*100mm

Length: 6M,or as per requirement

Finishing: Sanded,400 gloss,600--1000 mirror, brushed,etc.

Specification: 30*30*1.5

Packaging & Delivery

| Packaging Details: | Each pipe has the plastic bag to packed it ,and several will be bundled by weaving bag. |

|---|---|

| Delivery Detail: | 25-30 days, depends on customers' order quantity |

sus 304 stainless steel coil roll stainless steel price per kg

Hot selling 304 stainless steel welded square pipe with favorable price

| Specification | |

| Material | 304:0cr18ni9, 0cr17ni8 |

| 201:1cr17mn6ni5n,1cr13mn9ni1n | |

| 316:0cr17Ni12 | |

| or as customer's request | |

| Standard | ASTM A554, Q/GBS1-2005, customers' requests available |

| Size | 10*10mm,12*12mm,18*18mm,23*23mm,38*38mm,50*50mm, |

| 70*70mm,100*100mm,20*10mm,23*11mm,24*12mm, | |

| 25*13mm,36*23mm,40*20mm,50*20mm,60*15mm,75*45mm, | |

| 80*60mm,95*45mm,100*60mm,120*60mm,150*100mm, | |

| (or customized) | |

| Thickness | 0.25mm-5.0mm |

| Length | 6m or according to customers' request |

| Tolerance | Outer diameter:±0.2mm |

| Thickness:±0.05mm | |

| Length:±0.5mm | |

| Process Method | Cold drawn, Annealed with nitrogen protection, Ultrasonic welding, |

| Automatic shape, Polished, Packing. | |

| Ends | In plain end or bevelled ends or as customers' requirements |

| Finishing | A. Sanded |

| B. 400#-600# mirror | |

| C. Hairline brushed | |

| D. TIN titanlum plated | |

| E. HL brushed & mirror(two kinds of finishing for one pipe) | |

| Inner Packing | Plastic bag |

| Outer Packing | Standard gunny packed for each bundle, around 300-500kgs per |

| bundle, or customized according to customers' requests | |

| Application | Heat Interchangers and heaters |

| Decorations, constructions | |

| Oil and chemical industry | |

| Food industry and pharmaceutical industry | |

| Ship-building and automobile manufacturing | |

| Water transportation systems | |

| Performance | Rustless, stainless, good corrosion resistance, anti-wearing, good |

| appearance, excellent mechanical properties | |

| Certification | ISO, SGS,BV. |

| Welding Line Type | ERW(Electrical Resistance Weld) |

| Delivery Detail | 15~25 days, depends on customers' order quantity |

- Q: What is the average surface finish tolerance for steel coils?

- The average surface finish tolerance for steel coils can vary depending on the specific requirements and standards set by the industry or customer. Generally, it ranges from 10 to 20 micro-inches (0.25 to 0.5 micrometers), but it is important to consult the relevant specifications for the specific application.

- Q: I need help! Please help, I'm in Chemistry, and me and my friend Lucy are making a presentation on steel and iron, so how is steel manufactured? Thank you. :D

- Abed is off on some of the details... Steel is, by definition, Fe-C. There are thousands of different steel alloys and I am not aware of a single one that is simpkly Fe-Ag. There are different processes but the chemistry is basically the same, converting the iron compounds we dig out of the ground into metallic iron. Iron is typically found as iron oxides or iron sulfides (not with a lot of carbon). We add carbon so the carbon takes the oxygen from the Fe atoms making Fe + CO/CO2. Research iron smelting, iron ore, reduction of iron oxide, these types of things. You will find plenty of information because this is one of the most important industrial processes humans have. Good luck

- Q: Does te game end with broken steel? What is broken steel? I bouht it cuz my buddy said I should.

- In Broken steel, if you've already finished the game you get to continue playing the game and see events after you die in the original. With Broken steel, instead of dying in the end, your character was just knocked into a coma and you awaken and finish helping the Brotherhood of Steel fight the enclave. It also increases the level cap from 20 to 30 so you can level up more. Basically, you help kill the Enclave, transport fresh water while fighting off raiders etc.

- Q: im writing a book.-how is steel made? like, from what natural resources?-is there a type of factory that just prouduces steel to then be made into the various things made out of steel? if so, what kind of company might that be?-what is the first stage of steel, like, right after the other....ingrediants......are mixed, but before it is shaped into whatever its destined to be?thank you so much, i really appreciate it!

- That is an ENORMOUS subject that won't fit in this little box. Run an internet search on steel making. Essentially, steel is an alloy of iron and other metals chosen to give it the desired properties. These metals usually come from ores that are extracted from the earth. Actually, iron has too much carbon for most steel making purposes, and the carbon must be burned off. Iron is melted in a blast furnace, and oxygen is used to burn off the excess carbon. Then the molten metal is mixed with molten alloy metals and poured into molds to make ingots, which are blocks of steel of a size convenient for handling. Steel can also be made by re-melting scrap metal and adjusting the amounts of various adulterants or alloy metals at molten temperatures. The ingots are taken to rolling mills to be shaped into rods, pipes, sheet metal, and structural shapes. Molten iron and steel can also be poured into molds to produce complex shapes.

- Q: This question gets beat to death from what ive seen online but im going to ask it since im searching for a few new knives. The question is as the titles states what is the best steel for a general purpose knife? I plan on buying several different types of knives, Folders, fixed blades, ect. I will carry them around with me all the time for basically anything i can think of to use it for. The reason i ask this question here is because looking online everyone has a differnt veiw. Some say stainless is too soft while others say carbon will chip and is more brittle. Even looking at just a single type of steel, carbon fort instance everyone has a different opinion as to whats best leaving me kind of lost for what i should get. Maybe the better word would be What is a good general purpose steel?. Any advice is much appreciated!!!!

- Do you want apples or oranges? It's that kind of question. Here's my opinion. For large blades (over 6) 5160 or L-6 done properly makes a nearly unbreakable knife. I once pulled my 65lb vice out of the work bench with an 8 L-6 blade. As carbon content goes up edge holding increases but at the cost of overall strength. For smaller blades I prefer O-1 and 52100, these steels have about twice the edge holding as 5160 but cannot pass the 90deg bend test without breaking. 1095 is a fine steel, I prefer to make damascus from it, but when I do make a blade I want to show a temper line as this steel will do it well. Then we get into high alloy, D-2 is about as balanced as they come and for a smaller blade is second to none save the CPM steels. The CPM steels are very expensive and like the homogonous steel come in many alloys. As far as a chipping edge, that's more an indication of improper heat treating than anything. Carbon steel has more strength and edge holding potential than stainless. D-2 has enough chromium to be somewhat stainless but not beyond the threshold that grain growth becomes an issue. One last thing, the grind is important. The popular hollow grind cuts easily but is weak at the edge because it is thin. A flat grind has more mass and done properly cuts as well as the hollow. The convex is the strongest and is best suited for chopping or a polished edge to push through the material.

- Q: I was wondering because i just watched an episode of build it bigger on the discovery channel about the uss George bush, and when they were discribing it they said it was 500 tons of steel and 47,000 tons of aluminum. this kinda struck me as odd because i thought that it was mostly made of steel. and i would think that even if it was mostly aluminum, that the hull would be steel. and i think the hull would weigh more than 500 tons.

- An aircraft carrier is a pretty large hunk of metal. And it's mostly steel... at least its structure and weight bearing surfaces. As I recall, there was quite a bit of aluminum and other light stuff used for cosmetic stuff, like covering on interior bulkheads (walls). But the flight deck is about three football fields of steel... thick steel. Planes landing on an aircraft carrier don't land. They are trapped when their tail hook grabs an arresting cable, and kind of fall out of the sky. When they hit, they need something pretty substantial to break the fall. A carrier displaces an awful lot of water, but, and this is a guess, probably less than 100,000 tons... the one I was on displaced less than 80,000 tons. About 40 feet of it is underwater. Most of its crew live below or very close to the waterline. But there's enough above water to allow for the city that the carrier contains to operate pretty much like any city with a population of about 6,000. It has stores where you can buy almost anything, barbers, a hospital, dentists, doctors, fitness center, theaters, fast food places where you can have a hamburger made to order, restaurants where the food is free, a post office, gas stations, a radio studio and a television studio, newspaper, churches--a chapel as well as other places people can meet to hold religious services, even an airport. I looked at the ship's website. From what little information there is, it looks to be just a few feet larger than the old carrier I was on. If it weighs 500 tons, it has to displace 500 tons. Don't ask me how they do it... unless it was materials used during construction and removed.

- Q: What are the different types of steel coatings for coil protection?

- Some of the different types of steel coatings for coil protection include galvanized coatings, metallic coatings, organic coatings, and polymer coatings.

- Q: How are steel coils used in the production of kitchenware?

- Steel coils are used in the production of kitchenware by being shaped and formed into various utensils and appliances such as pots, pans, knives, and cutlery. The coils are typically cut, stamped, and pressed into the desired shape, then undergo further processes like polishing, coating, and finishing before being assembled into the final kitchenware products.

- Q: How are steel coils used in the manufacturing of seat structures?

- Steel coils are commonly used in the manufacturing of seat structures as they provide strength and durability. These coils are typically shaped and molded into springs that are then integrated into the seat cushions and frames. The steel coils help to provide support and enhance the overall comfort of the seats by ensuring proper weight distribution and minimizing sagging over time.

- Q: What are the common problems encountered with steel coils during production?

- There are several common problems encountered with steel coils during production. One of the most common issues is coil slippage, where the coils shift or slide out of place during handling or transportation. This can result in damage to the coils or pose a safety risk to workers. Another common problem is coil rusting or corrosion. Steel coils are susceptible to rusting if they come into contact with moisture or are not properly protected. Rust can compromise the structural integrity of the coils and lead to product defects or failure. Coil breakage is also a common problem. This occurs when the coils are subjected to excessive stress or tension, causing them to crack or break. Coil breakage can result from improper handling or storage, as well as production issues such as improper rolling or cooling processes. Coil surface defects are another common issue. These defects can include scratches, dents, or uneven surfaces on the coils. Surface defects can compromise the appearance and quality of the final product, making it unsuitable for certain applications. Lastly, coil contamination is a problem that can occur during production. Contaminants such as dirt, oil, or foreign particles can adhere to the surface of the coils, leading to quality issues or difficulties in further processing. Contamination can result from improper handling, inadequate cleaning processes, or poor environmental control. To mitigate these common problems, proper handling and storage practices are essential. This includes using appropriate lifting and transporting equipment, ensuring the coils are stored in a dry and clean environment, and implementing effective rust prevention measures. Regular inspections and quality control checks can also help identify and address any issues early on, preventing further damage and ensuring the production of high-quality steel coils.

Send your message to us

sus 304 stainless steel coil roll stainless steel price per kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords