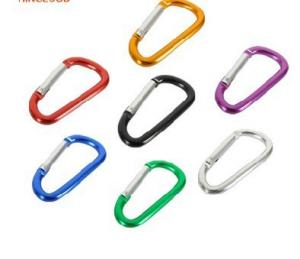

Aluminum Engraved Logo Carabiner Key Chain

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Buying Procedures

Enquiry: contact us by email, phone call, fax, Instant tools (Trademanager, MSN, Skype) and let us know your enquiry.

Discussion: specify the items you desire, confirm specification; OEM/ODM consultation.

Quotation: Prices offered and accepted.

Place order as per contract or discussion.

Proforma invoice offered to double confirm the order for both-side records.

Payment settled.

Order completed under our arrangement.

Goods shipped as per contracted term.

Goods arrive at local port or warehouse, depending on contracted term.

Support & re-ordering.

Specifications

D Shape Carabiner Key Chain

1.Logo ,OEM accept

2.CE,ROHS pass

3.promotional items

4.MOQ:1000pcs

| Product: | D Shape Carabiner Key Chain |

| MOQ: | 1000pcs |

| Material: | eco-friendly Aluminum |

| Color: | available or as Pantone Colors |

| Sample Time: | a.1-2day without logo,you pay the express fee; b.3-4 Days for printing logo,sample fee will be refund to you when place order. |

| Production Time: | a.Normal Time:10-15 Days for small quantity; b.It depends on order quantity |

| Packing: | 1pc/opp,100pcs/opp,1000pcs/ctn or customized |

| Logo: | Silk-screen Print,Laser,Engraved,Sticker, Epoxy etc |

| Shipping: | a.By air :DHL,UPS,FEDEX,TNT,EMS etc b.By sea |

| Payment Term: | T/T, Paypal, Western Union |

Packaging & Delivery

| Packaging Detail: | 1pc/opp,100pcs/opp,1000pcs/ctn or as client's request. |

| Delivery Detail: | available 10-15 Days,or it depends on order quantity |

Our Service

Your inquiry related to our product & price will be replied within 24hours.

Well-trained & experienced staff are to answer all your inquiries in English of course.

Working time: 8:30am ~6:00pm, Monday to Friday(UTC+8).

OEM & ODM projects are highly welcomed. We have strong R&D team here to help.

Your business relationship with us will be confidential to any third party.

Good after-sale service offered, please get back if you got question.

Suggestion

Please kindly check the packages after you receive the goods, if you got wrong products/ quality problem/short quantity, please get back to us as priority. Please note that you need to send us pictures of the defective items concerning this, and we will consider to replace or refund accordingly.

- Q: What measures should be taken to ensure safety when handling or using aluminum products?

- <p>When using aluminum products, safety precautions include handling with care to avoid sharp edges that may cause cuts. Ensure proper ventilation when working with aluminum powder or dust to prevent respiratory issues or fire hazards. Avoid using aluminum cookware for acidic or alkaline foods as it can react and leach aluminum into the food. Always follow the manufacturer's instructions for use and cleaning, and wear appropriate protective gear such as gloves and masks when necessary.</p>

- Q: This question asks for recent advancements or innovations in the technology related to aluminum.

- <p>Recent developments in aluminum technology include the advancement of aluminum-air batteries for energy storage, which offer a more sustainable and efficient alternative to traditional batteries. There's also the development of nanostructured aluminum alloys that exhibit superior strength and lightweight properties, making them ideal for aerospace and automotive applications. Additionally, research into aluminum recycling has led to more efficient processes, reducing waste and environmental impact. Lastly, advancements in aluminum electrolysis have improved energy efficiency, contributing to the sustainability of aluminum production.</p>

- Q: This question asks about the environmental effects caused by the extraction and processing of aluminum.

- <p>The environmental impacts of mining and processing aluminum are significant. Mining can lead to deforestation and habitat destruction, affecting biodiversity. The process of bauxite extraction releases large amounts of greenhouse gases, contributing to climate change. Additionally, the production of aluminum is energy-intensive, often relying on fossil fuels, which further exacerbates environmental issues. The release of toxic chemicals and heavy metals during processing can contaminate soil and water, posing risks to both ecosystems and human health. Moreover, the waste generated, such as red mud, can cause severe environmental damage if not properly managed. Overall, the aluminum industry has a substantial environmental footprint that requires sustainable practices to mitigate its effects.</p>

- Q: This question asks if there are any health risks related to cooking with pure aluminum pots and pans.

- <p>There are potential health risks associated with using pure aluminum pots and pans for cooking. Aluminum can leach into food, especially in acidic environments, which may lead to increased aluminum intake. High levels of aluminum in the body have been linked to neurological disorders, including Alzheimer's disease, although the connection is not definitively proven. Additionally, aluminum can interfere with the absorption of certain minerals, such as calcium and iron. For these reasons, it is generally recommended to use cookware made from materials that do not leach, such as stainless steel, cast iron, or non-stick coatings, to minimize exposure to aluminum.</p>

- Q: Is it safe to use pure aluminum for baking or roasting food in a traditional oven or grill?

- <p>While pure aluminum is a common material in cookware, it's not recommended for direct use in baking or roasting food in a traditional oven or grill. Aluminum can react with acidic foods, potentially leaching aluminum into the food. Additionally, aluminum foil can burn and create a hazardous situation. For baking or roasting, it's safer to use materials specifically designed for these purposes, such as parchment paper, silicone baking mats, or oven-safe dishes.</p>

- Q: Is there any risk to health from consuming food wrapped in aluminum foil?

- <p>Eating food wrapped in aluminum foil generally does not pose significant health concerns under normal circumstances. Aluminum is a stable element and does not leach easily into food at room temperature. However, at high temperatures, such as during grilling or baking, small amounts of aluminum might migrate into food. Most studies suggest that the amount of aluminum ingested from food wrapped in foil is minimal and not harmful. Nonetheless, it's advisable to avoid wrapping acidic foods or using foil in direct contact with food at high temperatures to minimize any potential exposure.</p>

- Q: This question asks about the typical applications of aluminum pipes in various industries and settings.

- <p>Aluminum pipes are commonly used in a variety of applications due to their lightweight, corrosion resistance, and high thermal conductivity. They are extensively used in the automotive industry for parts like radiators and heat exchangers. In construction, aluminum pipes are utilized for heating, ventilation, and air conditioning (HVAC) systems. They are also used in the beverage industry for conveying and cooling liquids, as well as in the aerospace industry for fuel and hydraulic lines due to their strength-to-weight ratio. Additionally, aluminum pipes are found in industrial settings for compressed air and gas lines, and in marine applications for fuel and water systems.</p>

- Q: Explain the interaction between aluminum and acids.

- <p>Aluminum reacts with acids to produce hydrogen gas and a salt of the acid. This reaction is a type of single displacement reaction where aluminum displaces hydrogen from the acid. The general reaction can be represented as 2Al + 6HCl 鈫?2AlCl鈧?+ 3H鈧? The aluminum metal is oxidized to form aluminum ions, while the hydrogen ions from the acid are reduced to form hydrogen gas. The specific products and reaction rates can vary depending on the type of acid and the conditions of the reaction.</p>

- Q: This question asks for a comparison of the positive and negative aspects of using aluminum as a material.

- <p>Aluminum has several advantages, including its lightweight nature, making it ideal for transportation and construction. It is also highly recyclable, with the recycling process requiring less energy compared to many other materials. Additionally, aluminum is corrosion-resistant, which extends the lifespan of products. On the downside, aluminum is less strong than some other metals, which can limit its use in certain applications. It also has a high thermal conductivity, which can be a disadvantage in situations where insulation is needed. Moreover, aluminum production is energy-intensive, contributing to environmental concerns.</p>

- Q: What are the various electronic components that utilize aluminum as a primary material?

- <p>Aluminum is used in several types of electronic components due to its good thermal conductivity, lightweight, and corrosion resistance. Some of the common components include: 1. Capacitors: Aluminum electrolytic capacitors are widely used for their high capacitance and low cost. 2. Heat sinks: Aluminum is a popular choice for heat sinks due to its ability to dissipate heat efficiently. 3. Semiconductors: Aluminum is used in semiconductor manufacturing, particularly for interconnects and as a barrier layer. 4. Conductive adhesives: Aluminum-filled adhesives are used for bonding components in electronics. 5. Wires and cables: Aluminum wire is used in some applications due to its lower weight compared to copper. 6. Reflectors: Aluminum is used in light reflectors for its reflective properties. 7. Housings and enclosures: Aluminum is used in the construction of electronic device casings for its strength and lightweight properties.</p>

Send your message to us

Aluminum Engraved Logo Carabiner Key Chain

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords