Strips of Aluminum for Industrial Cable & Wire - Aluminium Foil Strips

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Aluminium Foil Strip Specially for Industrial Cable & Wire

*No joint-points per 1000m

*Free samples

*Waterproof and acid attacks

*Surface: With or without gloss/mat effect

*Printed: clear, fastness, non-fade in high-temperature heat seal process

2.Why you want to choose us?

We've been specialized in aluminium foil for more than ten years, we know this product very well, we know what is good, what is the market price.

3.Specification and Application of Aluminium Foil Strip Specially for Industrial Cable & Wire

Alloy: 8011, 1050, 1060, 1035, 1145, 1235, 1100, 1200

Temper: O, H22, H24

Thickness: 0.1-2.0mm

Width: 30-1000mm

Core I. D.: 3" or 6"

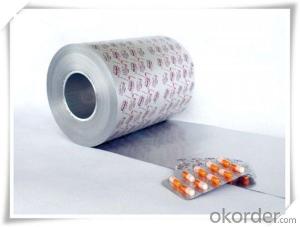

Application: Radio-shielding application of cables, wrapping and shielding application of cable. Cable foil is used as a skin for heat-insulating and electromagnetic shielding to provide high performance for Cable industry

Package: Standard Export wooden Case/Pallet

Remark: Specific requirement of alloy, temper or specification can be discussed at your request.

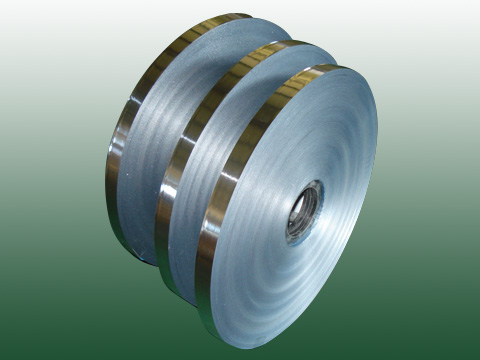

4.Pictures:

5.FAQ:

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: This question asks for the standard dimensions of aluminum strips commonly used for exterior siding on buildings.

- <p>The standard size of aluminum strips used for siding varies by manufacturer and specific product line. However, commonly, aluminum siding is available in widths ranging from 4 to 12 inches and lengths from 12 to 16 feet. The most common widths are 6 and 7 inches, while the standard length is often 16 feet. It's important to check with the specific manufacturer for the exact dimensions of the aluminum siding strips you are considering for your project.</p>

- Q: Inquiring about the durability of aluminum strips.

- <p>Aluminum strips are known for their durability. They are resistant to corrosion and weathering, making them suitable for long-term use in various environments. Their strength and light weight also contribute to their durability, allowing them to withstand significant stress without breaking. However, their longevity can be affected by factors such as the quality of the aluminum, the manufacturing process, and the specific conditions they are exposed to. Proper maintenance and handling can further enhance their durability.</p>

- Q: Which is the best aluminum alloy belt?

- Main products: aluminum, automotive, aviation, military board aluminum high-speed train ship plate, aluminum plate, cabinet board, high-end cosmetics cover material, mold piece aluminum pipe insulation board, special high Jingchao flat aluminum (whole plate flatness + 0.22mm), kraft paper, aluminum plate, aluminum plate, moisture-proof super hard Pre Stretch aluminum plate, aluminum plate, aluminum oxide, imported mirror plate, embossed aluminum, aluminum plate, aluminum plate, leveling drawing pattern aluminum and high precision high precision aluminum coil, aluminum strip, aluminum strip ultra narrow, extrusion rods, fine pull rods, Mo Guangbang, tube, seamless tube, aluminum forging, surface profile and other "off the spot wholesale cutting, retail

- Q: What distinguishes extruded aluminum strips from rolled ones in terms of manufacturing process and properties?

- <p>Extruded aluminum strips are formed by forcing aluminum through a die, creating a specific profile or shape. This process results in a more uniform cross-section and can produce complex profiles. Extruded strips are stronger and have better dimensional stability due to the grain flow being aligned with the direction of the extrusion. Rolled aluminum strips, on the other hand, are created by passing aluminum between rollers to achieve the desired thickness and width. This method is more suitable for producing thin, wide strips and is less costly for simpler profiles. Rolled strips may have some residual stresses and are not as strong as extruded ones, but they are more flexible and can be used in applications requiring formability.</p>

- Q: Is it possible to manufacture high-quality aluminum strips exclusively from recycled materials?

- <p>Yes, high-quality aluminum strips can be made from recycled materials. The recycling process allows for the production of aluminum that is often indistinguishable from primary aluminum in terms of quality. Recycling aluminum is more energy-efficient and has a lower environmental impact compared to mining and refining new aluminum. The process involves melting the scrap aluminum, which can be sourced from various products, and then casting it into new forms, such as strips. This not only conserves resources but also reduces waste, making it a sustainable practice in the aluminum industry.</p>

- Q: What factors should be considered to determine if an aluminum strip is appropriate for a specific project?

- <p>To determine if a particular type of aluminum strip is suitable for your project, consider the following factors: the strip's mechanical properties such as strength and ductility, its corrosion resistance, and its ability to withstand the specific environmental conditions of your project. Check the strip's thickness and width to ensure they meet your project's requirements. Assess the strip's surface finish and any required coatings or treatments. Consult the strip's technical specifications and compare them to your project's needs. If necessary, conduct tests or seek advice from material experts to ensure compatibility.</p>

- Q: This question asks about the various kinds of aluminum strips that can be found in the market.

- <p>Aluminum strips available on the market come in various types based on their thickness, width, alloy composition, and application-specific properties. Some common types include: 1. Pure Aluminum Strips: These are made from 99% pure aluminum and are known for their high ductility and conductivity. 2. Alloy Aluminum Strips: These are made from aluminum mixed with other elements like copper, magnesium, or silicon to enhance strength and durability. 3. Embossed Aluminum Strips: These have a textured surface and are used for decorative purposes or to improve grip. 4. Anodized Aluminum Strips: These are coated with a protective oxide layer to enhance corrosion resistance. 5. Painted or Coated Aluminum Strips: These have a protective or decorative layer applied to them. 6. Heat Treated Aluminum Strips: These are treated to improve their mechanical properties. The choice of aluminum strip depends on the specific requirements of the application, such as strength, weight, corrosion resistance, and cost.</p>

- Q: This question asks about potential hazards or issues that might arise from using aluminum strips as flooring material.

- <p>Safety concerns related to using aluminum strips for flooring include potential slip hazards, especially in wet conditions, due to the smooth surface of aluminum. There's also a risk of electrocution if the aluminum comes into contact with electrical wiring or outlets. Additionally, aluminum can conduct heat and cold, making the floor uncomfortable underfoot in extreme temperatures. The material may also dent or scratch easily, posing a tripping hazard. Lastly, concerns about the long-term health effects of aluminum exposure, though not fully proven, should be considered.</p>

- Q: Is it possible to utilize recycled aluminum to fabricate new aluminum strips?

- <p>Yes, recycled aluminum can be used to make new aluminum strips. Recycling aluminum is an efficient process that conserves energy and resources. The recycled aluminum is melted down and then reformed into new shapes, including strips. This process is not only environmentally friendly but also cost-effective, as it requires less energy compared to producing aluminum from raw materials. The recycled aluminum strips maintain the same properties as those made from new aluminum, making them suitable for various applications.</p>

- Q: This question asks whether aluminum strips can be utilized for both indoor and outdoor purposes or just one of them.

- <p>Aluminum strips can be used for both interior and exterior applications. They are known for their durability, corrosion resistance, and versatility, making them suitable for a wide range of uses. In interior applications, aluminum strips are often used for decoration, framing, and structural support. For exterior applications, they are used in construction, automotive, and signage due to their strength and resistance to weathering. Proper surface treatment and coating can further enhance their suitability for outdoor use.</p>

Send your message to us

Strips of Aluminum for Industrial Cable & Wire - Aluminium Foil Strips

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords