Sticker Mule Packaging Tape Width PVC Electrical Tape with Competitive Price and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

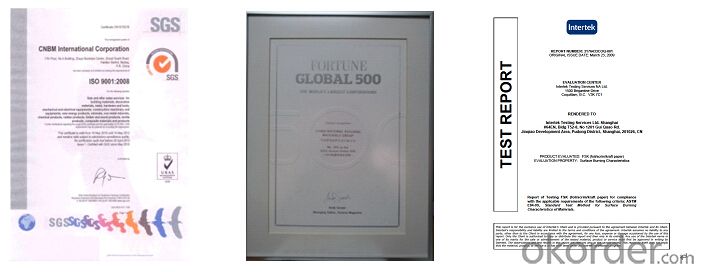

• World Top 500 Enterprises

• Resistance to cold, heat and aging

• Best quality and competitive price

• SGS&ISO9001, Customs Grade AA

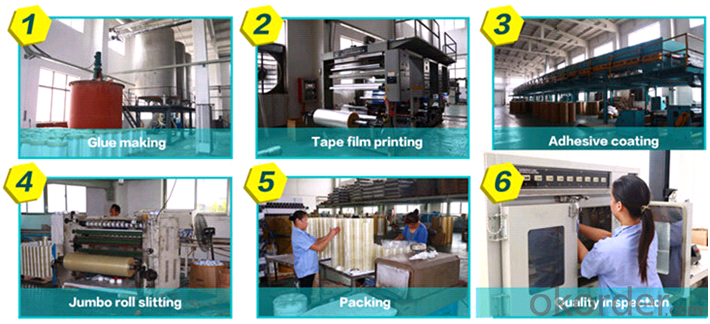

The PVC Electrical Tape is of PVC film as the carrier, coating with rubber based adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to electrical products.

The thickness of the tape can be customized.

PVC Electrical Tape is ideal for insulating, protection and color coding of electrical wires; may also be used as harness tape in automotive industry.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

| Standard size | 19mm*10m, 19mm*20m, 1.25m*10m, 1.25m*33m, etc |

| Thickness (micron) | 110 |

| Color | All Color Available |

| Adhesion to steel (N/cm) | 1.5 |

| Tensile Strength (N/cm) | 18 |

| Elongation at break (%) | 190 |

| Dielectric breakdown (V) | 600 |

| Flame Resistance (s) | <5 |

| Packing | Carton |

| Delivery | With 10-25days after receiving deposit |

| Payment | T/T & LC |

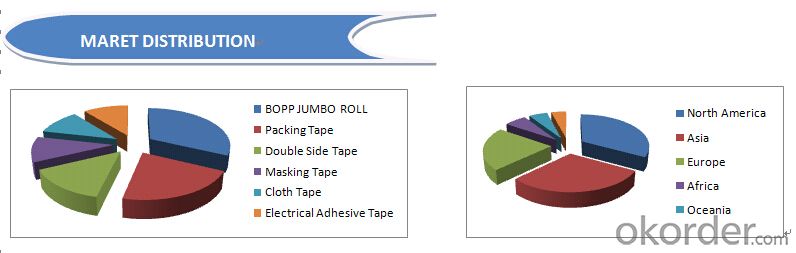

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

You are welcome to contact me at any time and visit the factory in China!

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled, but it depends on the type of tape and the recycling facilities available in your area. Most commonly used packaging tapes, such as clear or brown polypropylene tape, cannot be recycled with regular paper or plastic waste. However, some recycling centers accept certain types of tapes for recycling, such as those made from paper or with water-based adhesives. It is important to check with your local recycling center to determine if they accept packaging tape for recycling and what specific requirements they have. Additionally, removing the tape from cardboard boxes before recycling them can help improve the recycling process. If recycling is not an option, reusing packaging tape or disposing of it properly in the regular trash is recommended.

- Q: Can packaging tape be used for sealing plastic bags?

- Yes, packaging tape can be used for sealing plastic bags. It provides a strong and secure seal to keep the contents of the bag protected and secure.

- Q: Does packaging tape come in different dispenser options for ease of use?

- Yes, packaging tape does come in different dispenser options for ease of use. There are various types of dispensers available in the market that are specifically designed to make the task of sealing boxes or packages easier and more convenient. These dispensers come in different sizes, styles, and functionalities to cater to different needs and preferences. One common type of dispenser is the handheld dispenser, which is lightweight and compact, making it easy to handle and maneuver. These dispensers often have a serrated blade for cutting the tape and a comfortable grip for better control. They are ideal for small to medium-sized packaging tasks. For larger packaging jobs, there are also tabletop or benchtop dispensers available. These dispensers are designed to sit on a surface and hold the tape roll securely in place, allowing for efficient and continuous taping. They often have a built-in cutting mechanism for easy and precise tape cutting. Furthermore, there are automatic or electric dispensers that take convenience to the next level. These dispensers can automatically dispense and cut the tape with the push of a button, reducing the effort and time required for packaging tasks. They are particularly useful for high-volume or repetitive packaging needs. In summary, packaging tape does come in different dispenser options to suit various preferences and requirements. Whether you need a handheld dispenser for small tasks or an automatic dispenser for larger volumes, there are dispenser options available that can enhance the ease of use and efficiency of your packaging process.

- Q: Can packaging tape be used for sealing bubble wrap?

- Yes, packaging tape can be used for sealing bubble wrap.

- Q: How do I remove packaging tape residue?

- To remove packaging tape residue, there are a few simple methods you can try: 1. Rubbing alcohol: Dampen a clean cloth or paper towel with rubbing alcohol and gently dab the residue. Let it sit for a few minutes, then wipe away the residue. Repeat if necessary. 2. Goo Gone or similar adhesive remover: Apply a small amount of adhesive remover to a cloth or paper towel and gently rub the residue. Allow it to sit for a minute or two, then wipe away the residue with a clean cloth. 3. Warm soapy water: Mix a few drops of dish soap with warm water. Dampen a cloth or sponge with the mixture and gently rub the residue. Rinse the area with clean water and dry it thoroughly. 4. Heat: If the residue is on a hard surface like glass or plastic, you can use heat to soften the adhesive. Use a hair dryer on a low setting and hold it a few inches away from the residue. Once the adhesive becomes soft, gently scrape it off with a plastic scraper or your fingernail. Remember to test any method on a small, inconspicuous area first to ensure it doesn't damage the surface.

- Q: How do you choose the right packaging tape for your needs?

- When it comes to selecting the appropriate packaging tape for your requirements, there are various factors to take into consideration. To begin with, ponder over the nature of the items you will be packaging. If you are dispatching weighty or bulky items, you will need a tape that is sturdy and long-lasting, such as a heavy-duty or reinforced tape. Conversely, if you are packaging lightweight items, a standard packaging tape may suffice. Moving forward, contemplate the surroundings in which the package will be stored or transported. If the package will be exposed to extreme temperatures or moisture, it is advisable to opt for a tape that is resistant to these conditions, such as a weather-resistant or waterproof tape. This will ensure that your package remains intact and safeguarded throughout its journey. Furthermore, take into account the surface onto which the tape will be affixed. If you are packaging boxes with smooth surfaces, a standard adhesive tape will suffice. However, if you are packaging boxes with rough or textured surfaces, you may require a tape with a stronger adhesive, such as an acrylic or hot melt tape, to ensure proper adhesion. Additionally, consider the length and width of the tape roll. If you will be packaging a large number of items, it may be preferable to select a tape roll with a longer length to minimize the need for frequent replacements. Similarly, if you are packaging larger boxes, a wider tape roll may provide better coverage and security. Lastly, take your budget into account. Packaging tapes are available in a range of prices, so it is crucial to strike a balance between your needs and your budget. While it may be tempting to opt for cheaper options, bear in mind that investing in a higher-quality tape can save you time, effort, and potential damages in the long run. By considering the type of items, environmental conditions, surface texture, roll length and width, and your budget, you can choose the appropriate packaging tape that caters to your specific needs and offers the necessary strength, durability, and security for your packages.

- Q: What are the benefits of using tear-resistant packaging tape?

- Using tear-resistant packaging tape comes with various advantages. To begin with, the use of tear-resistant packaging tape provides added security and protection for your packages during transit or storage. The tape's strong adhesive and tear-resistant material guarantee its integrity, preventing any tampering or accidental tearing of the packaging. This helps to maintain the contents' integrity and minimizes the risk of damage or loss. Furthermore, tear-resistant packaging tape offers greater durability and longevity compared to regular packaging tapes. Its sturdy design and resistance to tearing make it perfect for packaging heavy items, those with sharp edges, or those susceptible to rough handling. This ensures that the tape remains intact throughout the entire shipping process, reducing the need for re-taping or potential damage to the package. In addition, tear-resistant packaging tape often possesses weather-resistant properties, enabling it to withstand various environmental conditions. It is designed to resist moisture, extreme temperatures, and UV exposure, making it suitable for long-distance shipping or storage in different climates. This prevents the tape from deteriorating or weakening, ensuring that your packages remain securely sealed and protected. Moreover, tear-resistant packaging tape is user-friendly and provides a professional finishing touch to your packages. Its strong adhesive allows for quick and secure bonding to different surfaces such as cardboard, plastic, or metal. This ensures that the tape stays in place and does not unravel or loosen during transit. Additionally, tear-resistant packaging tape is available in a range of sizes and colors, allowing you to personalize your packaging and create an aesthetically pleasing presentation for your customers. To summarize, the advantages of using tear-resistant packaging tape include enhanced security, increased durability, weather resistance, ease of use, and a professional appearance. By investing in tear-resistant packaging tape, you can ensure that your packages are well-protected, reduce the risk of damage or tampering, and enhance the overall shipping experience for both you and your customers.

- Q: How do I prevent packaging tape from getting tangled?

- To prevent packaging tape from getting tangled, ensure that the tape roll is placed on a dispenser or a stationary surface with the sticky side facing down. Additionally, avoid pulling the tape too quickly or at an angle, as this can cause it to twist and tangle. Taking these precautions will help maintain the tape's smooth flow and prevent any frustrating tangles.

- Q: What are the alternatives to packaging tape?

- There are several alternatives to packaging tape that can be used for securing packages or boxes. Some of the popular alternatives include: 1. Duct Tape: Duct tape is a strong adhesive tape that can be used as an alternative to packaging tape. It is known for its durability and ability to stick to various surfaces. 2. Masking Tape: Masking tape is a type of adhesive tape that is less sticky compared to packaging tape. It is commonly used in painting or crafting projects, but can also be used to secure packages. 3. String or Twine: String or twine can be used to secure packages by wrapping it around the box and tying it securely. This method is often used for packages that do not require strong adhesion. 4. Packaging Straps: Packaging straps are commonly made of plastic or polyester and can be used to secure packages by strapping them tightly around the box. They provide a strong and secure alternative to packaging tape. 5. Adhesive Glue: Adhesive glue can be used as an alternative to packaging tape, particularly for small packages or envelopes. It is essential to choose a glue that is strong enough to securely seal the package. 6. Paper or Kraft Tape: Paper or kraft tape is a water-activated tape that is commonly used for sealing packages. It requires wetting the tape to activate the adhesive, providing a strong and secure seal. 7. Zip Ties: Zip ties are plastic ties that can be used to secure packages by fastening them tightly around the box. They are commonly used for securing large or heavy packages. When considering alternatives to packaging tape, it is important to assess the specific needs of the package, such as its size, weight, and handling requirements, to determine the most suitable option.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

Send your message to us

Sticker Mule Packaging Tape Width PVC Electrical Tape with Competitive Price and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches