Hot rolled steel wire rod in coils low carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 18421 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Drawing Grade wire rods are used by downstream industries for various applications such as making

wires for welded mesh, nails, hangers, screws, chain link & gabion fencing, wire nets, barbed wires

and binding wires.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

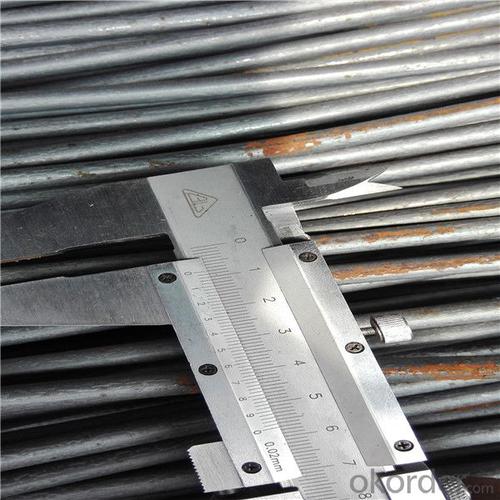

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make

for wire mesh.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

FAQ:

1.Q:Can you accept mixed order?

A: Yes, mixed acceptable .

2. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

3. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

4. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How is steel wire rod used in the manufacturing of wire forms for window screens?

- Steel wire rod is an essential material used in the manufacturing of wire forms for window screens. It serves as the primary building block for creating the wire mesh structure that forms the screen. To begin with, the steel wire rod is first carefully selected based on its quality and properties. The rod needs to have specific tensile strength, elasticity, and corrosion resistance to ensure a durable and long-lasting window screen. Once the appropriate steel wire rod is obtained, it is then processed through a series of manufacturing steps. The rod is first cleaned and then drawn through a series of dies to reduce its diameter to the desired size. This process is known as wire drawing and is crucial for obtaining a finer wire that can be easily manipulated into the desired shape. After wire drawing, the steel wire is typically further processed through a galvanizing or coating process. This step involves applying a protective layer of zinc or other coatings to enhance the wire's resistance to corrosion and increase its lifespan. The galvanized or coated wire is then further processed to remove any excess coating and ensure a smooth surface. Finally, the processed steel wire is ready to be formed into window screens. The wire is fed into wire forming machines, where it is shaped into the desired form, such as a rectangular or square mesh pattern. The wire is carefully woven or welded together to create a sturdy and secure structure that can withstand external forces and serve as an effective barrier against insects and debris. In summary, steel wire rod plays a crucial role in the manufacturing of wire forms for window screens. It provides the necessary strength, durability, and corrosion resistance required for a high-quality screen. Through various manufacturing processes, the steel wire rod is transformed into a finely drawn wire and then formed into the desired shape, resulting in a reliable and functional window screen.

- Q: How is steel wire rod used in the production of wire for cable trays?

- Steel wire rod is used in the production of wire for cable trays as it serves as the primary raw material. The wire rod is first processed and drawn into the desired thickness and shape to form the wires that are then used to create the cable trays. These wires provide the structural integrity and support necessary for cable management and organization within the trays.

- Q: What are the main factors affecting the market segmentation of steel wire rod?

- The main factors affecting the market segmentation of steel wire rod include the demand from various industries such as construction, automotive, and manufacturing, the quality and specifications required by different end-users, the geographical location and infrastructure of potential markets, the price competitiveness and availability of substitutes, and the evolving regulations and standards in the steel industry.

- Q: What are the common production processes for molybdenum-coated steel wire rod?

- The common production processes for molybdenum-coated steel wire rod include cleaning and pre-treatment of the steel wire, application of molybdenum coating through techniques like electroplating or physical vapor deposition, curing or drying of the coating, and finally, quality control checks before the wire rod is ready for use.

- Q: How are steel wire rods used in the production of wire cables?

- Wire cables require steel wire rods as an essential raw material for their production. These rods are usually made from carbon or alloy steel and are shaped into long, cylindrical forms. They undergo several stages of processing to be converted into wire cables. Initially, the steel wire rods are hot rolled. This involves passing the rods through a series of rollers to gradually decrease their diameter and increase their length. This hot rolling process enhances the steel's ductility and strength, making it suitable for further processing. After hot rolling, the steel wire rods undergo a process called cold drawing. This process involves pulling the rods through a series of dies at room temperature to further decrease their diameter and increase their length. Cold drawing refines the steel's surface finish and improves its mechanical properties, such as tensile strength and flexibility. Once the desired diameter and length are achieved, the steel wire rods are used in the production of wire cables. They are fed into a wire drawing machine, where they are pulled through a series of dies to further decrease their diameter. This drawing process ensures the desired diameter and surface finish of the wire cables. Following the wire drawing process, the steel wire rods typically undergo a heat treatment to enhance their mechanical properties. This involves heating the rods to a specific temperature and rapidly cooling them to attain the desired hardness and strength. The final step in wire cable production involves stranding the steel wires together to form a cable. The individual steel wires are twisted in a specific pattern known as a lay, providing the cable with the desired strength and flexibility. This stranding process is often followed by a coating or galvanizing process to protect the wire cables from corrosion. In conclusion, steel wire rods are vital in wire cable production. They undergo various processes, including hot rolling, cold drawing, wire drawing, heat treatment, and stranding, to create strong, durable cables suitable for a wide range of applications.

- Q: How is steel wire rod used in the construction of bridges?

- Steel wire rod is commonly used in the construction of bridges as it provides strength, durability, and flexibility. It is primarily used for reinforcing concrete structures, such as bridge decks and foundations, to enhance their load-carrying capacity and structural integrity. Additionally, steel wire rod is also utilized for suspension cables and stay cables in cable-stayed bridges, offering high tensile strength to support the bridge structure efficiently. Overall, steel wire rod plays a crucial role in ensuring the safety and longevity of bridges by reinforcing and providing structural support.

- Q: How is steel wire rod used in the manufacturing of wire for suspension bridges?

- The manufacture of wire for suspension bridges relies heavily on steel wire rod, a vital component. Initially, a steel mill uses a technique called hot rolling to produce the wire rod. This involves heating the steel and passing it through a series of rollers to shape it into a long, continuous rod. The rod is then cooled and cut into shorter lengths, which are further processed to create wire for suspension bridges. During the manufacturing process, the steel wire rod undergoes several steps. Firstly, it is cleaned and coated with a protective layer to prevent corrosion. Next, it is drawn through a set of dies, gradually reducing the wire's diameter while increasing its length. This drawing process strengthens the wire and enhances its tensile strength, making it suitable for suspension bridges. Once the wire has been drawn to the desired size, additional processing is carried out to meet the specific requirements of suspension bridge construction. This may involve heat treatment to improve mechanical properties, such as fatigue resistance and flexibility. After processing, the wire is spooled onto large reels and transported to the construction site. There, it is unwound from the reels and used to form the main cables of the suspension bridge. These cables consist of multiple strands of steel wire twisted together to provide the necessary strength and stability. The selection of steel wire rod for suspension bridge manufacturing is based on its high strength, durability, and resistance to environmental factors like corrosion. It undergoes rigorous testing and quality control measures to ensure it meets the required specifications and standards. In summary, steel wire rod is a crucial element in the construction of suspension bridges. It provides the strength and stability needed to support the bridge's weight and withstand external forces. The use of steel wire rod in suspension bridge construction is essential for ensuring the safety and longevity of these structures.

- Q: What are the environmental benefits of recycling steel wire rod?

- Recycling steel wire rod provides various benefits to the environment. The foremost advantage is the conservation of natural resources. By recycling steel, we can decrease the necessity for extracting and mining iron ore, which is the primary raw material utilized in steel production. This lessens the environmental impact of mining activities, which encompass deforestation, habitat destruction, and soil erosion. Moreover, recycling steel wire rod aids in reducing energy consumption and greenhouse gas emissions. The production of steel from recycled materials requires considerably less energy compared to the production from virgin materials. Additionally, the recycling process emits fewer greenhouse gases, such as carbon dioxide, in comparison to manufacturing steel from scratch. By recycling steel wire rod, we can help mitigate climate change and diminish our carbon footprint. Furthermore, recycling steel wire rod assists in waste reduction and conserves landfill space. Steel is a long-lasting material that can be recycled indefinitely without losing its properties. By recycling steel wire rod, we can divert this material from ending up in landfills, where it would occupy valuable space and contribute to pollution. Additionally, recycling steel wire rod diminishes the necessity for new steel production, which can result in waste generation and environmental pollution during the manufacturing process. Lastly, recycling steel wire rod aids in safeguarding ecosystems and wildlife. Mining activities for iron ore extraction can have devastating effects on ecosystems, including forest destruction, water source contamination, and disruption of wildlife habitats. By reducing the demand for new steel production through recycling, we can minimize the negative impacts on ecosystems and preserve biodiversity. In conclusion, recycling steel wire rod presents numerous environmental benefits, such as the conservation of natural resources, reduction in energy consumption and greenhouse gas emissions, waste reduction, and protection of ecosystems and wildlife. By opting to recycle steel wire rod, we can contribute to a more sustainable and eco-friendly future.

- Q: What are the common industry standards for steel wire rod?

- The common industry standards for steel wire rod include the American Society for Testing and Materials (ASTM) standards, such as ASTM A510 and ASTM A510M, which specify the general requirements for carbon and alloy steel wire rods. Additionally, the International Organization for Standardization (ISO) has standards like ISO 16120-1 and ISO 16120-2 that provide guidelines for steel wire rod production and testing. These standards ensure the quality, dimensions, tolerances, and mechanical properties of steel wire rod, promoting consistency and compatibility in the industry.

- Q: How is steel wire rod used in the manufacturing of wire rope slings?

- Steel wire rod is the primary raw material used in the manufacturing of wire rope slings. The rod is first drawn into wire and then twisted together to form strands, which are further twisted or braided to create the wire rope. The strength and durability of steel wire rod make it ideal for withstanding heavy loads and providing reliable lifting and rigging solutions in various industries.

Send your message to us

Hot rolled steel wire rod in coils low carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 18421 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords