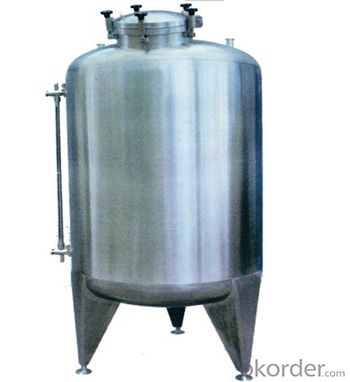

steel vessel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

steel vessel

Our factory supplies manufacturing various stainless steel tanks with orwithout jacket, agitation etc.

1.Specifications

1)Materials: SUS304, SUS316.

2) Design Tem: asper design

3)Design P: as perdesign

4)Capacity:as per design

5)Manufacture standard: ASME GB/T

6)Design service:provided

7)After-salesservice: provided

8)Service life:fifteen years

2. Our products contain 5 assortments :

1)chemicalsassortments(ethanol,methanol,furfuraldehyde,etc.)

2) food assortments,

3) dairy assortments,

4) pharmaceutical assortments,

5) beverage assortments.

3. Here is the main products of stainless steel tanks:

1) Water tank,

2)storage tank,

3)prcoess tank,

4)beer tank,

5)dairy tank,

6)reactor tank,

7)fermenting tank,

8)vacuum tank,

9)any style of tank made of stainless steel ,platform,worktable,goodsshelf,wheel car,tank car,whatever made of stainless steel products.

If you have any interested in our products please contact me feel free.

- Q: Pressure container A1. What does it mean to have a single layer?

- The A1 aptitude includes single-layer containers and multi-layer packing containers. If you only have a single layer of manufacturing license, you can only make single-layer containers, and you can't manufacture multiple layers of packing containers.

- Q: Is the bathhouse a pressure vessel for direct combustion

- You can look at the TSG R0004-2009 fixed pressure vessel safety technology monitoring protocol, which is detailed

- Q: What is a simple pressure vessel?

- (a) container by cylinder head peace, convex head (not including QiuGuanXing head), Or is composed of two convex head; (2) of the cylinder head and take over the main pressure parts such as the material is carbon steel, Austenitic stainless steel; (3) the design pressure is less than or equal to 1.6 MPa; (4) volume less than or equal to 1000 l. (5) the product of working pressure and volume greater than or equal to 2.5 MPa, L, and Less than or equal to 1000 mpa l.; (6) media as air, nitrogen and medical distilled water evaporation of water vapor; (7) design temperature is greater than or equal to - 20 ℃, the highest working temperature is less than or Is equal to 150 ℃; (8) the flame welding container directly.

- Q: Analysis of the main reasons of pressure vessel accident

- I have seen some magazine articles, statistics, Use reason more, the quality of the container itself Magazine is "China special equipment safety"

- Q: One of the questions in the boiler pressure vessel exam tomorrow

- You see the special equipment safety inspection ordinance.

- Q: Where is the pressure vessel usually used?

- Industries such as energy-petrochemicals and chemical fertilizers are available

- Q: The air compressor can be used for special equipment

- If the air tank pressure reaches 0.1 MPa, it is a special equipment.

- Q: Excuse me each expert, A company's qualification as A level of pressure vessels, including A1 and A2, excuse me this kind of qualifications specific to produce what types of pressure vessel, thank you all for the first.

- Is the pressure container design and manufacturing license level: Class A is divided into A1: super high pressure vessel, high pressure vessel (single layer, multi-layer); A2: the third type of low, medium pressure vessel; A3: spherical container; A4: non-metal pressure vessel. A5: medical YangCang Class C is divided into C1: rail tankers; C2: car tankers, long tube trailers; C3: container. Class D is D1: the first type of pressure vessel; D2: type 2 low, medium pressure vessel. SAD class refers to the stress analysis design of pressure vessels.

- Q: Air conditioning compressor is the pressure vessel

- The air conditioning compressor itself is not a pressure vessel, and the top can be a pressure vessel

- Q: Where is the pressure vessel generally high in weld

- The Chinese national standard GB150 is specified in this way.

Send your message to us

steel vessel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords