Steel Pipe with High Quality and Best Price Q345 and so on

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Steel Pipe Q345 Descrption:

steel welded pipe is actually a cover term, covering a wide range of alloy and making them suitable for different attributes that are used in a very wide and large numbers of different industries. Stainless steel pipe is resistant to erosion, highly flexible, powerful, easy to use, and can be done in distinct approaches, which means that more and more stainless steel was used as a construction material for large-scale, high impact buildings. It can be molded, rolling, and it can create amazing shapes to make it perfect, It is used as experimental buildings, The use of steel pipe welding of large stainless steel covers other examples.

2、Main Features of the Steel Pipe Q345:

·Highly demanded

·Durable

·Reliable

·resist corrosion

·reasonable price

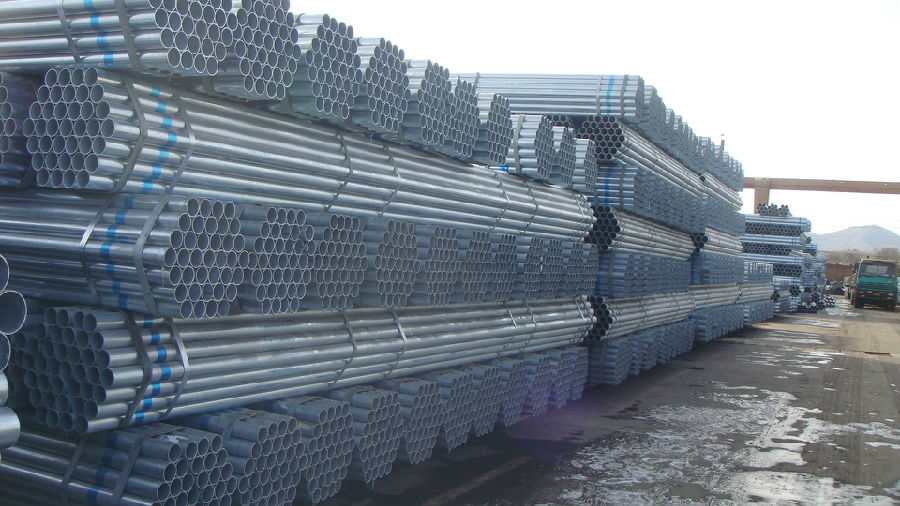

3、Steel Pipe Q345 Images:

4、The Steel Pipe Q345 Specification:

Standard JIS, DIN, ASTM

JIS G3445-2006, JIS G3444-2006, JIS G3446-2004, DIN EN 10216-1-2004, DIN EN 10217-1-2005, DIN EN 10305, ASTM A106-2006, ASTM A53-2007, ASTM A789-2001, ASTM A1020-2002, ASTM A179-1990, ASTM A199Grade Cr-Mo alloy, Mo, ST35-ST52, Q195-Q345, CrNi alloy

15CrMo, 10CrMo910, 30CrMo, 15Mo3, 16Mo, St37, St52, St42, St45, Q235, Q345, Q195, Q215, Cr17Ni8, 1Cr13Mn9Ni1NThickness 2 - 50 mm Section Shape Round Outer Diameter 10 - 900 mm Secondary Or Not Non-secondary Application Structure Pipe Technique EFW Certification API Surface Treatment Paint Special Pipe API Pipe Alloy Or Not Non-alloy

Specifications

1.W.T from 2mm to 70mm

2.OD from 10 to 1200mm

3.product by our own factory

4.on time dilivery

5、FAQ of Square Tube:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What is the outer diameter and wall thickness of the welded steel pipe of national standard DN250?

- DN (nominal diameter) 250 is generally the industry said 273, welded steel pipe (spiral steel pipe) thickness is generally between 6-8mm, more common.

- Q: Are steel pipes affected by UV rays?

- Yes, steel pipes can be affected by UV rays. Prolonged exposure to UV radiation can lead to the degradation of the protective coatings on steel pipes, causing them to corrode and weaken over time. It is important to implement proper protective measures, such as applying UV-resistant coatings or using protective covers, to mitigate the impact of UV rays on steel pipes.

- Q: Can steel pipes be galvanized?

- Yes, steel pipes can be galvanized.

- Q: What material is RHS in the steel tube?

- RHS is a rectangular hollow section steel. The RHS structure represents a rectangular hollow section steel.

- Q: How do you calculate the bending moment of a steel pipe?

- The bending moment of a steel pipe can be calculated using the formula M = F * d, where M is the bending moment, F is the applied force, and d is the distance from the neutral axis to the point where the bending moment is being calculated.

- Q: How are steel pipes coated to prevent corrosion?

- Steel pipes are coated to prevent corrosion using various methods and materials. One common method is applying a protective layer of paint or epoxy on the surface of the pipe. This coating acts as a barrier between the steel and the external environment, preventing moisture and corrosive substances from coming into direct contact with the metal. Another technique involves using a process called galvanization, where the steel pipes are coated with a layer of zinc. Zinc is highly resistant to corrosion and acts as a sacrificial anode, meaning it will corrode in place of the steel if any damage occurs to the coating. This sacrificial protection ensures that the steel remains intact and corrosion-free. Additionally, steel pipes can be coated with polyethylene or polypropylene materials through a process called fusion bonding. In this method, the plastic material is melted onto the steel surface, creating a strong bond that provides excellent resistance against corrosion. This type of coating is commonly used in offshore and underground pipelines. Furthermore, another technique for preventing corrosion is the application of a layer of corrosion-resistant alloy onto the steel pipe. This alloy is typically a combination of metals such as nickel, chromium, and molybdenum, which provide superior protection against corrosion in harsh environments. Overall, the choice of coating method depends on various factors such as the operating conditions, the type of corrosive substances present, and the expected lifespan of the steel pipes. By effectively applying these coatings, steel pipes can be safeguarded against corrosion, extending their durability and ensuring the integrity of the infrastructure they are used in.

- Q: How can two smooth steel pipes be joined? The size of the two pipe is different (except for welding)

- Butt fastener: used for connecting two steel pipe jointsThin-walled stainless steel pipe, the national standard consists of three parts, respectively on the thin stainless steel pipe connection, the sealing ring of raw materials of various specifications of O type thin wall stainless steel pipe diameter and wall thickness of pipe and rubber have clear requirements, in order to ensure the quality of the whole pipeline, pipeline safety and guarantee system durability. The connection mode is clamp type and ring type.

- Q: How are steel pipes used in the telecommunications industry?

- Steel pipes are used in the telecommunications industry primarily for the installation and protection of underground fiber optic cables. These pipes provide a sturdy and durable infrastructure for the cables, ensuring their safety from external factors such as weather conditions or accidental damage. Additionally, steel pipes are also used for the construction of telecommunication towers, providing the necessary strength and support for antennas and other equipment.

- Q: What are the different types of steel pipe supports for high-temperature applications?

- There are several types of steel pipe supports designed specifically for high-temperature applications. Some common ones include rigid supports, such as rigid hangers and clamps, which provide strong support and prevent pipe movement. Expansion joints are also used to accommodate thermal expansion and contraction in the pipes. Additionally, spring supports and constant supports are employed to absorb vertical movement and maintain a consistent pipe elevation.

- Q: How are steel pipes used in the manufacturing of solar power systems?

- Steel pipes are commonly used in the manufacturing of solar power systems for various purposes. They are used to support and secure solar panels, providing a sturdy framework for installation. Steel pipes are also used for the transportation of fluids, such as water or heat transfer fluids, within the solar power system. Additionally, steel pipes are utilized in the construction of solar power plant infrastructure, including the installation of mounting structures and foundations. Overall, steel pipes play a crucial role in the manufacturing and functioning of solar power systems.

Send your message to us

Steel Pipe with High Quality and Best Price Q345 and so on

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords