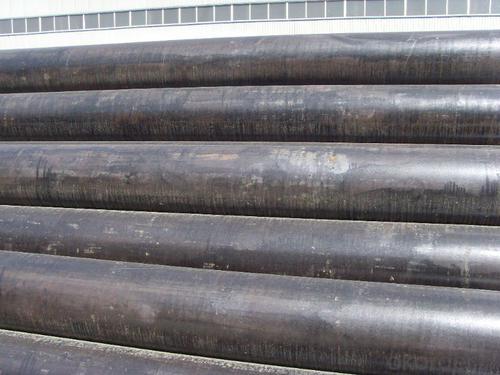

Steel pipe for carbon seamless ,A53(A,B), cnbm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Thickness: 6 - 50 mm Section

Shape: Round,r

Outer Diameter: 33 - 600 mm

Secondary Or Not: Non-secondary

Application: Fluid Pipe

Technique: Hot Rolled,Hot Rolled,Cold Drawn,Hot Expanded Certification: API Surface Treatment: Beveled end or plain end or varnished as per buyer

Special Pipe: API Pipe Alloy Or Not: Non-alloy

Brand Name: XPY(Xinpengyuan)

Length: 6-12m or according to clients' requirements

Standard: BS 3059-2,JIS G3454-2007,GB 5310-1995,GB 3087-1999,GB/T 8163-1999,GB/T 8162-1999,GB 6479-2000,DIN 1629/3,DIN 2448,ASTM A106-2006,ASTM A53-2007,API 5CT,API 5L,BS,JIS,GB,DIN,ASTM,API

- Q: What are the different methods of pipe protection for steel pipes?

- There are several different methods of pipe protection for steel pipes, each serving a unique purpose and providing varying levels of protection. Some of the common methods include: 1. Coatings: Coatings are applied on the external surface of steel pipes to protect them from corrosion and other environmental factors. Coating materials can include various types of paints, epoxies, or polymers. These coatings create a barrier between the pipe surface and the surrounding environment, preventing the steel from coming into contact with corrosive elements. 2. Wrapping: Wrapping involves using a protective material, such as tape or shrink wrap, to cover the steel pipe. This method provides a physical barrier against moisture, chemicals, and other corrosive substances. Wrapping is often used in combination with coatings to enhance the overall protection. 3. Cathodic Protection: Cathodic protection is an electrochemical method used to protect steel pipes from corrosion. It involves connecting the steel pipe to a sacrificial anode, typically made of zinc or magnesium. The anode corrodes instead of the pipe, which helps to prevent the steel from deteriorating. This method is commonly used for buried or submerged pipelines. 4. Thermal Insulation: Thermal insulation is used to protect steel pipes from extreme temperatures. Insulating materials, such as foam or mineral wool, are applied around the pipe to minimize heat transfer. This method is particularly important for pipes carrying hot fluids or exposed to extreme weather conditions. 5. Vibration Dampening: Vibration can cause stress and fatigue on steel pipes, leading to potential damage. To protect against vibrations, various techniques can be employed, such as using vibration damping pads or installing supports and clamps. These methods help to absorb and dissipate the energy generated by vibrations, reducing the risk of pipe failure. 6. Concrete Coating: For pipelines installed underwater or in highly corrosive environments, concrete coating is often used. A layer of concrete or a cement-based mortar is applied to the steel pipe, providing both mechanical protection and resistance to corrosion. It is important to select the appropriate method of pipe protection based on the specific application, environmental conditions, and desired level of protection. Regular inspection and maintenance are also crucial to ensure the long-term integrity of steel pipes.

- Q: What are the different types of steel pipe connections for oil and gas pipelines?

- The different types of steel pipe connections for oil and gas pipelines include threaded connections, welded connections, and flanged connections. Threaded connections involve screwing the pipes together using a threaded end, which ensures a secure fit. Welded connections involve permanently joining the pipes together using welding techniques such as butt welding or socket welding. Flanged connections involve attaching flanges to the ends of the pipes and bolting them together, providing a strong and leak-proof connection.

- Q: Can steel pipes be used for underground water lines?

- Yes, steel pipes can be used for underground water lines.

- Q: What is the maximum length of steel pipes available in the market?

- The market offers steel pipes in varying maximum lengths, which are influenced by factors like steel type, manufacturing capacity, transportation restrictions, and customer demands. Generally, steel pipes can be produced up to 12 meters (40 feet) or even longer. However, it is crucial to consider that handling and transporting longer lengths might pose challenges, necessitating specialized equipment or techniques. Ultimately, the industry and customers' specific requirements and capabilities determine the maximum length of steel pipes available in the market.

- Q: What are the different methods of pipe joining for steel pipes?

- Steel pipes can be joined using various methods, each with its own benefits and drawbacks. These methods include: 1. Butt Welding: Two steel pipes are welded together by beveling or facing their ends to form a V-groove. Molten metal is then used to fill the groove, creating a strong and long-lasting joint. 2. Socket Welding: A socket is welded onto the end of a steel pipe, and another pipe is inserted into the socket and welded in place. This method creates a leak-proof and corrosion-resistant joint. 3. Threaded Joint: Steel pipes can be joined by threading the ends and using a threaded coupling or union to connect them. This method is commonly used for smaller pipes and allows for easy disassembly and reassembly. 4. Flanged Joint: For larger pipes, a flange is attached to the end of each pipe, and the flanges are fastened together with gaskets using bolts. This method is commonly used in industries such as oil and gas, water treatment, and chemical processing. 5. Grooved Joint: Grooving machines are used to create a groove on the outside of the pipe. A coupling or fitting is then inserted into the groove and secured with bolts or clamps. This method is quick to install and allows for easy disassembly and reassembly. The choice of pipe joining method depends on factors such as pipe size, application, and desired strength and durability. Each method has its own advantages and disadvantages.

- Q: What does cathodic protection of steel tubes mean?

- Applied current: a macro cell consisting of a protected metal piece and an insoluble auxiliary component. The negative electrode of the battery is connected to the metal to be protected. The power supplies the electrons so that the metal is not corroded by missing points.

- Q: What are the different coating options available for steel pipes?

- There are several different coating options available for steel pipes, including epoxy coatings, polyethylene coatings, zinc coatings, and asphalt coatings. These coatings are applied to the exterior of the pipes to provide protection against corrosion, abrasion, and other environmental factors. Each coating option offers different benefits and is chosen based on the specific requirements of the project or application.

- Q: What are the different types of flanges used with steel pipes?

- There are several types of flanges commonly used with steel pipes, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, and blind flanges. These flanges are used to connect and secure steel pipes in various industrial applications, each offering specific advantages depending on the requirements of the piping system.

- Q: What are the common standards for manufacturing steel pipes?

- The common standards for manufacturing steel pipes include the American Society for Testing and Materials (ASTM) standards, the International Organization for Standardization (ISO) standards, and the American National Standards Institute (ANSI) standards. These standards cover various aspects such as material composition, mechanical properties, dimensions, testing procedures, and quality control requirements to ensure the consistency and reliability of steel pipes.

- Q: How does galvanization protect steel pipes from corrosion?

- Galvanization protects steel pipes from corrosion by forming a protective zinc coating on the surface of the pipes. This zinc coating acts as a barrier between the steel and the surrounding environment, preventing moisture and corrosive elements from reaching the steel. Additionally, if the zinc coating is damaged, it sacrificially corrodes before the steel, further protecting the pipes from rust and corrosion.

Send your message to us

Steel pipe for carbon seamless ,A53(A,B), cnbm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords