Scotch Packaging Tape 3710 - Stationery Adhesive Tape BOPP Adhesive Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Of Stationery adhesive tape BOPP Adhesive Tape:

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description Of Stationery adhesive tape BOPP Adhesive Tape:

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

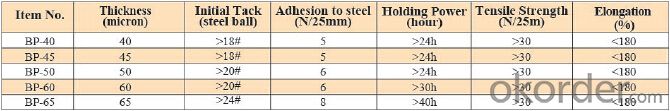

Typical Physical Reports Of Stationery adhesive tape BOPP Adhesive Tape:

Packaging Of Stationery adhesive tape BOPP Adhesive Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1280mm; length according to customers’ requirements

FAQ Of Stationery adhesive tape BOPP Adhesive Tape:

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- Using pre-printed packaging tape with warning messages has several benefits. Firstly, it helps to ensure the safety of the package contents and the individuals handling them. The warning messages act as a visual reminder of any potential hazards or special handling instructions, reducing the risk of accidents or mishandling. Secondly, it saves time and effort by eliminating the need for separate warning labels or writing instructions on the packaging. The pre-printed tape provides a clear and professional warning message that can be easily recognized by anyone involved in the packaging process. Lastly, it enhances the overall professionalism and branding of the company. The customized warning messages on the tape can include the company's logo, contact information, or any other branding elements, making the package stand out and leaving a positive impression on the recipient.

- Q: What are the advantages of using packaging tape over other sealing methods?

- There are several advantages of using packaging tape over other sealing methods. Firstly, packaging tape provides a strong and secure seal that can withstand the rigors of shipping and handling. It is designed to adhere to various surfaces, including cardboard, plastic, and metal, ensuring that the package remains intact throughout its journey. Secondly, packaging tape is easy to use and can be quickly applied to seal a package. Unlike other sealing methods such as glue or staples, tape does not require any additional tools or equipment. This saves time and allows for efficient packaging processes. Furthermore, packaging tape offers versatility in terms of size and strength. It is available in different widths and thicknesses, allowing for customization based on the specific needs of the package. Whether you are sealing a small envelope or a large box, there is a packaging tape option that suits your requirements. Another advantage of packaging tape is its cost-effectiveness. Compared to other sealing methods, tape is generally more affordable. It offers a cost-efficient solution for businesses and individuals who frequently ship or package items. In addition, packaging tape is tamper-evident, providing an added layer of security. Once the tape is applied, any attempt to tamper with the package will be evident due to the broken or damaged tape seal. This helps to deter theft and provides peace of mind to both the sender and recipient. Lastly, packaging tape is easily removable. It can be peeled off without leaving any residue or damaging the packaging materials. This is particularly important for packages that may require resealing or for recipients who may want to reuse the packaging. Overall, the advantages of using packaging tape over other sealing methods include its strength, ease of use, versatility, cost-effectiveness, tamper-evident properties, and ease of removal. These benefits make packaging tape a reliable and efficient choice for sealing packages.

- Q: Does packaging tape come in different dispenser options for ease of use?

- Packaging tape is available in different dispenser options, making it easier to use. The market offers various types of dispensers that are specifically designed to simplify the process of sealing boxes or packages. These dispensers come in different sizes, styles, and functionalities to accommodate different needs and preferences. One popular type of dispenser is the handheld dispenser. It is lightweight and compact, making it easy to handle and maneuver. These dispensers usually have a serrated blade for cutting the tape and a comfortable grip for better control. They are ideal for small to medium-sized packaging tasks. For larger packaging jobs, tabletop or benchtop dispensers are available. These dispensers are designed to sit on a surface and securely hold the tape roll in place, allowing for efficient and continuous taping. They often have a built-in cutting mechanism for easy and precise tape cutting. Moreover, there are automatic or electric dispensers that offer even more convenience. With these dispensers, you can effortlessly dispense and cut the tape with the push of a button, saving time and effort. They are especially useful for high-volume or repetitive packaging needs. To summarize, different dispenser options are available for packaging tape to cater to various preferences and requirements. Whether you need a handheld dispenser for small tasks or an automatic dispenser for larger volumes, there are dispenser options that can enhance the ease of use and efficiency of your packaging process.

- Q: Can packaging tape be used for sealing pharmaceutical or medical supplies?

- Yes, packaging tape can be used for sealing pharmaceutical or medical supplies. However, it is important to note that not all packaging tapes are suitable for this purpose. It is recommended to use packaging tapes that are specifically designed for medical or pharmaceutical applications. These tapes are often made of materials that provide a strong and secure seal, ensuring the integrity and safety of the contents. Additionally, medical or pharmaceutical packaging tapes may also feature special attributes such as tamper-evident properties or sterilization indicators to meet the specific requirements of these industries.

- Q: For the moment the yellow rubber stamp [] how to use paper and pen, pen parts packaging tape?

- Circle, circle, lap, wrap the tail and cut off the excess!

- Q: How do I prevent packaging tape from peeling off?

- In order to prevent packaging tape from peeling off, there are several steps that can be taken: 1. Surface cleanliness is crucial: Prior to applying the tape, it is essential to ensure that the surface is thoroughly cleaned and devoid of any dust, dirt, or moisture. Wipe the surface using a clean cloth or paper towel and ensure it is completely dry. 2. Select the appropriate tape: It is important to use a high-quality packaging tape specifically designed for secure adhesion. Look for tapes with robust adhesive properties and a durable backing material. 3. Exert pressure: Once the tape has been applied to the surface, firmly apply pressure along its entire length using your hands or a roller. This will aid in forming a secure bond between the adhesive and the surface, preventing any peeling. 4. Employ additional tape: If there are concerns about the tape peeling off, it is possible to reinforce it by applying extra tape along the edges or corners. This will provide additional strength and stability to the initial tape. 5. Steer clear of extreme temperatures: Extreme temperatures can adversely affect the adhesive properties of the tape, resulting in peeling. It is advisable to avoid storing or using packages in areas with excessive heat, cold, or humidity. 6. Proper package storage: If packages are being stored or shipped, it is important to ensure they are kept in a cool, dry location. Avoid stacking heavy objects on top of them, as this can exert pressure on the tape and cause it to peel off. By adhering to these steps, it is possible to guarantee that the packaging tape remains securely in place, preventing any undesired peeling.

- Q: How does packaging tape perform on rough or uneven surfaces?

- Packaging tape typically does well on rough or uneven surfaces, thanks to its adhesive properties that allow it to stick firmly to most surfaces, even those that aren't perfectly smooth. The tape is designed to mold itself to the shape of the surface, ensuring a tight seal and preventing any possible lifting or peeling. However, it's important to note that the effectiveness of packaging tape on rough or uneven surfaces can vary depending on the specific type and quality of the tape being used. Some tapes may have stronger adhesion or more flexible backing materials, which can further improve their performance on rough or uneven surfaces. In certain situations, it may be necessary to apply more pressure or use multiple layers of tape to ensure a secure bond. Moreover, it's worth considering alternative packaging materials, like stretch film or strapping, for particularly rough or irregular surfaces, as they may offer a more dependable solution.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent packaging tape from tearing during application, make sure to use a high-quality tape that is specifically designed for packaging. Additionally, ensure that the surface of the package is clean and dry before applying the tape. Avoid using excessive force while pulling the tape, instead apply it smoothly and evenly. If you're still experiencing tearing, you can try using a tape dispenser or moistening the tape slightly to make it more pliable.

- Q: Can packaging tape be used for heavy-duty packaging?

- Yes, packaging tape can be used for heavy-duty packaging. It is designed to provide strong adhesion and durability, making it suitable for securing and sealing heavy or bulky items during transportation or storage.

Send your message to us

Scotch Packaging Tape 3710 - Stationery Adhesive Tape BOPP Adhesive Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords