Standards can be customized environmental protection resin

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Standard Conventional size: 1220mm (width) * 2440mm (length) * 15mm (thickness), size, thickness, material types are customized according to customer requirements. Material thickness can be selected 5mm, 9mm, 12mm, 15mm, 18mm, 21mm, 25mm and so on

Advantages detailed analysis:

1.Color persistence

Synthetic resin tile surface material is the selection of imported super high weather resistant engineering resin produced. In the natural environment with exceptional durability, it is even long-term exposure to ultraviolet light, moisture, heat, cold, poor conditions, can still maintain its color stability. According to the United States from Arizona and Florida and other areas with high sun exposure to outdoor use results show that can ensure ten years color change Delta E = 5. Synthetic resin tile xenon arc weathering test obtained in terms of 450 sunlight samples in different parts of the conclusion.

2.Excellent anti load

Synthetic resin tile has good bearing capacity. In the lower temperature region, even if the roof perennial snow, synthetic resin tile will not produce surface damage and fracture phenomenon. After the test, the support spacing of 660mm, loading 150 kg, tile will not have cracks and damage.

The advantages of resin tile and contrast color steel tile:

Synthetic resin tile waterproof extremely strong, due to the material can be a large number of materials to reduce the roof load, after the installation of the overall very beautiful. The installation mode is basically consistent with a lot lighter than steel tile, color steel tile material, handling more convenient, can greatly reduce the work intensity of workers. Acid and alkali corrosion resistance, fire resistance, sound insulation, reach B1 level strong weatherability, life can reach 35 years

- Q: Which friends know how to remove the plastic film on the sun?

- In the PC sun panels and accessories installed when fixed, it is best to tear the protective film 30mm to 50mm, this is to avoid the accessories to suppress the protective film pressure. But should pay attention to is not too much to expose, or easy to install the operation because of scratching the sun plate.

- Q: Who can tell me, plastic hollow board and PC sun board in the end what is the difference?

- Compared with the PC sun panels, it has the following advantages: The price is cheap, it's only one-third the price of a PC sunshine board. ?? Plastic hollow board for the software structure, roll packaging can be transported, saving shipping. Veneer area, the largest can be made 200m2 each (100 meters long × 2 meters wide). Easy to install greenhouse, greenhouse low cost. Long life, more than 10 years of the greenhouse is still in use.

- Q: What is the difference between PC stamina and PC sunboard?

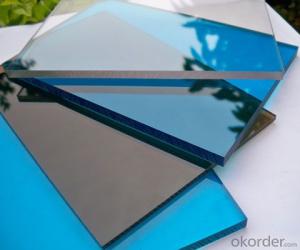

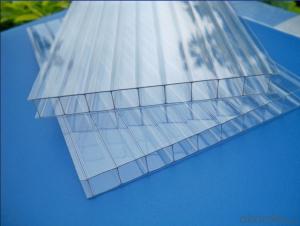

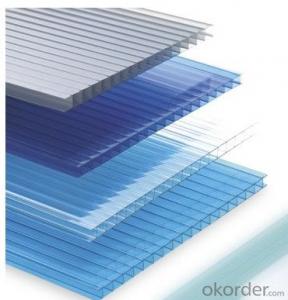

- In fact, from their nickname we can simply distinguish, PC sun plate is also called hollow board, hollow board, as the name suggests is the middle is hollow. PC Nai Liban also known as solid board, of course, is solid.

- Q: What is the difference between a hollow board and a sunboard?

- Sunshine board is one of the lighting board, most of the lighting board is made of FRP and the sun is made of PC (polycarbonate) made, a little PC board warranty period is 10 years and 15 years, The better FRP lighting board warranty period of 20 years, 25 years. Performance comparison, although the thermal conductivity of the lighting board than the sun board is low, but the lighting board is usually a single layer, thermal conductivity than the sun plate. That is the summer sun exposure, then, under the lighting board room temperature to be higher. Light transmittance, carrying capacity under normal circumstances 2 can meet.

- Q: PC sun panels and color steel plate how to bond

- Sun panels and color plate need to have two corrugated width of the stack, the use of sealant at the same time, with self-tapping screws fixed on the purlins. Such a practice to meet the requirements.

- Q: Sunny plate that is a transparent that I want to use the home screen 4mm thickness can be about how much a square

- Generally solid and transparent is the stamina board, do the bath on the screen in general 3mm, 4mm can, the specific price depends on what you need the quality of the

- Q: What is the difference between the PC and the PC board?

- Sometimes the particles may be slightly cheaper, because its surface is uneven, with less raw materials so the cost will be low.

- Q: Can the sun board cover the bedroom?

- At the time of installation, the organizer of the construction must understand the text description and precautions printed on the protective film and explain to the operator, with particular attention to which side of the standard. Do not wrong. Sun board for the polycarbonate transparent plate of the trade name, referred to as PC board, is widely used in the international high-strength, light transmission, noise, energy-saving new decorative materials. It has a light, weather, super, flame retardant, sound insulation of the excellent performance, access to architectural design, decoration works, environmental engineering, advertising industry widely recognized.

- Q: What are the differences between plastic endurance boards and sun panels?

- PC board in two kinds - solid for the endurance board, hollow for the hollow board or sun panels.

- Q: Sunshine board price per square meter, PC sun board how much money a square meter

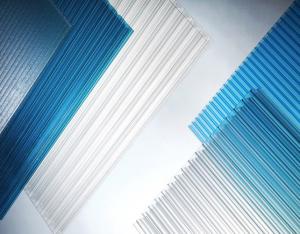

- Thickness of 6mm - 16mm, the general price of 25 yuan -100 yuan / ㎡, the thickness of the sunshine plate is more commonly used, the structure is divided into two layers, three, four, X type, meter type, honeycomb type.

Send your message to us

Standards can be customized environmental protection resin

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords