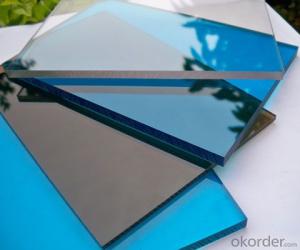

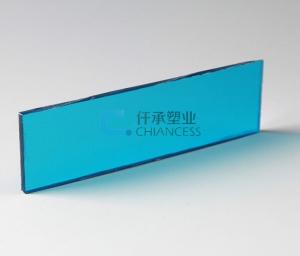

Shock resistance to low temperature and environmental protection resin

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features and Benefits

1 . lasting color: Synthetic resin tile surface materials are made of imported ultra-high weatherability Engineering resin produced. By having exceptional durability in the natural environment, even if it is long-term exposure to ultraviolet light, moisture, heat, cold harsh conditions, can still maintain the stability of its color.

2 . excellent resistance to load: good carrying capacity. In the lower temperature region, even if the roof perennial snow, it does not produce surface loss and breakage. After testing, in the case of support from the 750mm, the load 150kg, tile does not produce cracks and damage.

3 . sound effect: The experiment proved: when subjected to external noise heavy rain, high winds, synthetic resin tile has good noise absorption effect.

4 . impact resistance, good low temperature resistance: has a strong ability to withstand external. The test 1 kg steel ball dropped from 1.5M high freedom will not crack, impact resistance at low temperatures is also very significant, after 10 freeze-thaw cycles (-20 to +50 degrees Celsius) without hollowing, blistering, peeling, cracks phenomenon.

5 . excellent corrosion resistance: long-term resist acid, alkali, salt and other corrosive chemicals. Experimental results show: soak for 24 hours without a chemical reaction in salt, alkali and various acids below 60%. Ideally suited for acid rain-prone areas and coastal areas, the effect is particularly significant.

Product Specifications:

Standard Conventional size: 1220mm (width) * 2440mm (length) * 15mm (thickness), size, thickness, material types are customized according to customer requirements. Material thickness can be selected 5mm, 9mm, 12mm, 15mm, 18mm, 21mm, 25mm and so on

Advantage

1. Persistent color

2. Excellent load resistance

3. Sound: Experimental proof

4. Impact resistance, good low temperature resistance

5. Excellent corrosion resistance

6. Excellent thermal insulation properties

7. Excellent self-cleaning performance

8. Stability

9. Excellent waterproof performance

10. Excellent electrical insulation properties

11. Fire resistance

12. Installation is quick

13. Green

- Q: Which friends know how to remove the plastic film on the sun?

- You can try with a soft cloth or sponge dipped in a neutral soap or detergent scrub the sun surface dust, dirt, and then rinse thoroughly with water, and finally to a soft cloth to dry.

- Q: How to correctly identify the quality of pc sunshine board and pc durability plate method

- Look at the product surface. Protective film paste flat, no shedding. Indicating that manufacturers of product production, sales attention. Of course, some bag companies, small companies pay attention to packaging, because this customer is like moon cakes, in the use, the best choice for the strength of the old company

- Q: To build a sunshine shed, with Cortron PC patience board or good sun board?

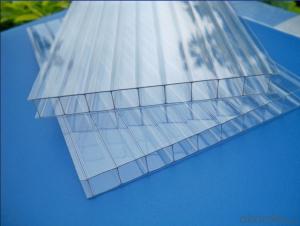

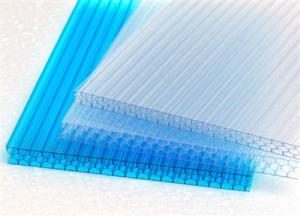

- Nai Liban board a little better, but the cost of the durability plate is too high, the sun will have a lot of concessions, the general use of four sun panels, structural stability, high quality performance. Pc sun panels for the production of polycarbonate as the main raw material. At present the international widely adopted a high-intensity, translucent, sound insulation, energy-saving new high-quality decorative materials. Sunshine plate in the mid-80s into the building materials, decorative materials market. Than the laminated glass, folder glass, tempered glass, insulating glass more light, weather, super, flame retardant, sound insulation of the excellent performance, due to the special quality of the sun plate. Get the architectural design, decoration works, environmental engineering, advertising industry generally recognized.

- Q: Pc sun panels and frp lighting board what are the two differences

- Pc sun plate is a polycarbonate material hollow board used in outdoor building lighting top to achieve anti-ultraviolet, weather, anti-aging effect.

- Q: What is the difference between PC stamina and PC sunboard?

- In addition, the use of sun panels and endurance boards are the same in many ways, but there are also differences, such as sun panels are generally used in the stadium lighting roof, greenhouse lighting ceiling, warehouse lighting roof and so on. Stamina board is used to make shields, outdoor light boxes, advertising signs, etc. are more common. So customers in the choice of PC sun panels, PC Nai Liban or need to be based on their actual use and needs to choose.

- Q: Can the stencils be made in the bathroom?

- PC particle board characteristics 1, the surface of the plate can reflect the direct light on the plate of direct exposure, after this treatment can reduce the sunlight penetration. 2, the surface of the board can increase the surface area, while increasing the heat, can extend the service life of the plate. 3, the surface of the plate per square meter distribution of 15,000-18000 pieces of anti-diamond-type particles, reflection, refraction effect can enhance the blocking capacity.

- Q: PC sun board life years?

- In fact, the warranty period of the sun board is the warranty of the yellowing index, depending on the UV (UV stabilizer) into the number of cases, under normal circumstances, 50μ UV yellowing index warranty for 10 years

- Q: Where the PC stamina board and the sun board sell more price is also cheaper

- PC sheet prices from high to low are all very cheap to have a lot, you have a lot of expensive, the key depends on what you want quality, and said quality generally refers to the service life, you want to use a few years warranty PC Sun board. The price from 20 to 70 yuan, from 5 to 10 years warranty.

- Q: What is the difference between the PC and the PC board?

- Sometimes the particles may be slightly cheaper, because its surface is uneven, with less raw materials so the cost will be low.

- Q: What is the difference between the sunboard and the Capron board?

- The difference between the sunboard and the cardboard: Sunshine board is collectively referred to as mainly produced by PC / PET / PMMA / PP material, one of which is sunshine board, also known as pc sunshine board, polycarbonate as the main raw material manufacturing. PC sun panels are commonly used in the international plastic building materials, there are other architectural materials (such as glass, plexiglass, etc.) can not match the advantages of "not broken glass," said. Widely used in greenhouse / industrial plant, decoration, advertising signs, parking shed, channel lighting rain pond residential, commercial lighting sky, exhibition lighting, sports venues, swimming pool, warehouse lighting business, factories, sports venues lighting ceiling and sun shelter, Agricultural greenhouses, aquaculture and flower greenhouses, as well as telephone booths, newsstand, station and other public facilities, highway noise, advertising decoration field.

Send your message to us

Shock resistance to low temperature and environmental protection resin

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords