High Efficiency Automatic Scourer Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

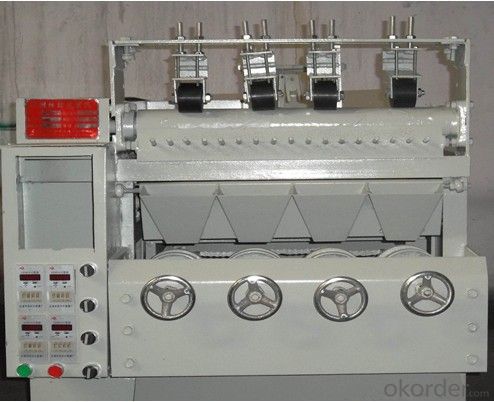

automatic spiral scourer making Machine

1.voltage:380v/220v

2.setting wire:6 wires (scourers)

3.machine weight:516kgs

2014 hot sale Automatic Spiral Scourer Machine from China

1.description:

Automatic scourer machine for 6 wires 3 balls

The machine can produce any size and any weight cleaning balls(scourers);In intelligent design,CNC automatic management with ball(scourers)Sub-standard sizes ,so it can control zero-error precision on the weight of each cleaning ball.After separation into the cleaning balls automatically it also can send the cleaning balls with the conveyor belt,Automaticlly,ball tight and losen can be adjusted according to the weight and sizes automatically.So ,it can produce balls with variety and attractive appeara

Item Name | 8 wire 4 balls machine for making spiral scrubber | |

| Model | QSD-P4 | |

| Output | 12-15kg per hour | |

| Item Size(cm) | 180*100*165 | |

| Power | 2.2KW | |

| Power Supply | 380 or 220 volt | |

| Package Way | export shipping wood case | |

| Net Weight | about 350kgs | |

| Gross Weight | 450KGS | |

| Wood Case Diamension | 145x105x122cm 95x85x95cm | |

| 1*20FT qty | about 12pcs | |

| 1*40HQ qty | about 29pcs | |

2.pictures:

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- Look at that oil and then choose the emulsifier To use the all-around emulsifier for oil and other oil Used for lubricating oil, mechanical oil and mine Oil, clutch oil, gear oil, brake oil, engine oil, ink, demoulding oil, compressor oil, refrigeration oil, vacuum pump oil, the internal combustion engine oil (1: diesel engine oil. 2: gasoline engine oil. 3: ship oil), oil bearing, guide Rail oil, hydraulic oil, hydraulic oil, metal processing oil dynamic tools, electrical insulating oil, oil, heat conduction oil, rust-proof oil, special occasions, oil, turbine oil, quenching oil, fuel oil, oil have oil selection and other occasions Engine oil emulsifier, no oil emulsifier is the domestic initiative of non-toxic + environmental protection + high efficiency emulsifier. For the removal of oil emulsifier and oil emulsifier, nano-oil emulsifier is used for the removal of oil and oil emulsifier in addition to oil and inorganic oil

- Q: Is it better to clean insulators with ultrasonic cleaning equipment or to clean them?

- Quantity of equipment, small amount of artificial. There are also better cleaning agents that can be cleaned without ultrasound.

- Q: Procter &gamble has some common cleaning equipment in the cleaning of the property

- Electric escalator cleaning machine: the clean and dry cleaning and drying of electric escalators are the best choice, easy to operate, multi-function and clean environment. Special design for escalators with different softness to choose from. Vacuuming, "water" as a filtration system, and equipped with a drain. The brush cover is equipped with special cleaner distributing device, easy to operate, easy to clean or change. Solve the problem of the traditional cleaning escalator.

- Q: What is the issue of cleaning equipment? Is there a difference between industrial cleaning equipment and common equipment?

- Industrial high pressure cleaning machine: product positioning is machine equipment Industrial high pressure cleaner is designed according to the condition of industrial cleaning, generally USES a relatively low speed, forged steel crankshaft crankshaft, crosshead bearing alloy, independent lubrication system and electrical control cabinet. The main characteristics are: high reliability, high load capacity, high safety factor. The materials used in machine manufacturing are quite elegant, including manufacturing accuracy, heat treatment of materials, testing and strength tests. The highest rated working pressure of the industrial high pressure cleaning machine is much higher than the highest rated working pressure of the commercial high pressure cleaning machine. 2: under the same technical parameters (pressure flow), industrial high pressure cleaner can effectively continuously working time is more than commercial grade high pressure cleaner can effective working hours continuously.

- Q: Characteristics of cleaning equipment of cleaning equipment

- High pressure cleaner using high pressure water jet cleaning technology, which is in the 1960 s the rise of a technology, widely used in the removal of incrustation scale proliferation, oil and other hydrocarbons residue coking, also can remove all kinds of coating stab stick coagulation soil lipid layer of gypsum, pigment, rubber, plastic, etc

- Q: What is the pool cleaning equipment

- TR - 300 pool cleaning machine (the queen) : by motor sediment and suspended solids in the suction machine, the water through the filter to filter inside the machine, put the clean water, so as to achieve the cleaning effect. Hd5/11c water gun: applied to the outside of the building, the outside of the building, the external gun, the garage, the floor of the workshop, the kitchen, the vehicle, the pool cleaning, etc.

- Q: The main parameters of ultrasonic cleaning equipment

- Frequency: greater than 20KHz, which can be divided into low frequency, medium frequency, high frequency 3 segments. 2. The power density, power density = transmission power (W)/launch area (cm2) usually acuity 0.3 W/cm2, the higher the power density of the ultrasonic and cavitation effect is stronger, the faster, the better cleaning effect. But for delicate, surface finish, the high power density of long time can be used to "cavorate" the surface of the object. 3. The ultrasonic frequency, ultrasonic frequency is lower, the easier the cavitation in the liquid, the strength is big, has the stronger, is suitable for the workpiece (coarse, dirty) at the beginning of washing. High frequency of ultrasonic direction, suitable for fine cleaning. 4. Clean temperature: generally speaking, ultrasonic at 30 ℃ and 40 ℃ when cavitation effect is best. The higher the temperature, the greater the effect. Normally when actual application of ultrasonic wave, using the working temperature of 50 ℃ to 70 ℃.

- Q: The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- It's usually a person + device approach

- Q: How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- Do not use steel wire ball, long emperor is galvanized tank, our long emperor CRDF25, with that kind of absorbing water, small pieces of clean with warm water and detergent to wash, then dry with a towel

- Q: How many kinds of cleaning equipment are there for cleaning companies?

- Other cleaning: sofa machine, air conditioner, steam engine, vacuum suction machine, multi-function washing machine, polishing machine, stone retread machine, etc

Send your message to us

High Efficiency Automatic Scourer Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches