Stainless Steel Coil Cold Rolled 201 Surface 2B with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Stainless Steel Coil Cold Rolled 201 Descriptions

Stainless Steel 201 is a new kind of Austenite stainless steel by used Mn, N replace Ni. The steel has good corrosion resistance and hot / cold processing performance, instead of 304 stainless steel products for used in the not high of corrosive environment, such as indoor, inland city outdoor etc.

2. Main Features of the Stainless Steel Coil Cold Rolled 201

Product name: Stainless Steel Coil Cold Rolled 201

Thickness: 0.2mm to 1.5mm

Technical: Cold Rolled

Width: 10mm to 1240mm

Type: 200 Series

Length: As customer's requested

Standard: JIS, SUS, AISI, ASTM

Grade: 201-J1, 201-J4, AISI201, AISI202…

Finish: BA, 2B, 8K, NO.3, NO.4, HL…

MOQ: 25 Metric Tons

Hardness: Low Hard(190 HV Max); Half Hard(240-280HV); Full Hard(42-60 HRC)

Ship Term: FOB any port, China or CFR Destination port

Delivery Time: 15 to 20 day after the receive the deposit or 100%LC

Payment Terms: TT 30% for deposit, Balance against the copy of B/L, or 100%LC

Packaging: By wooden pallet, wooden case or according to customer's request

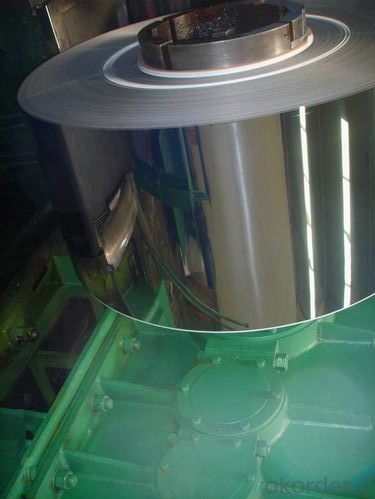

3. Stainless Steel Coil Cold Rolled 201 Images

4. Stainless Steel Coil Cold Rolled 201 Specifications

Mechanical Property Contrast | YS (Mpa) | TS (Mpa) | EL(%) | HV | REMARK |

Stainless Steel 201 | 426 | 880 | 52 | 224 | 1.0t |

Stainless Steel 304 | 285 | 710 | 58 | 165 | 1.0t |

Stainless Steel 200 Series Chemicals Contrast (wt. %) | ||||||||

Chemicals | C | Si | Mn | Cr | Ni | N | Other | |

205 | 0.12-0.25 | ≤0.75 | 14.0-15.0 | 16.5-18.0 | 1.0-1.75 | 0.32-0.4 | ||

JIS, | 201 | ≤0.15 | ≤1.0 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - |

201L | ≤0.03 | ≤0.75 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | 17.0-19.0 | 4.0-6.0 | ≤0.25 | - | |

201LN | ≤0.03 | ≤0.75 | 6.4-7.5 | 16.0-17.5 | 4.0-5.5 | 0.1-0.25 | Cu≤1.0 | |

India | 201-J1 | ≤0.08 | ≤0.75 | 7.0-8.0 | 15.0-17.0 | 4.0-5.0 | ≤0.1 | Cu≤1.5 |

201-J3 | ≤0.08 | ≤0.75 | 9.0-10.5 | 14.0-16.0 | 2.0-3.0 | ≤0.15 | Cu≤2.0 | |

201-J4 | ≤0.10 | ≤0.75 | 8.5-10.0 | 15.0-16.0 | ≤1.2 | ≤0.2 | Cu≤2.0 | |

America | 204 | ≤0.03 | ≤1.0 | 7.0-9.0 | 15.0-17.0 | 1.5-3.0 | 0.15-0.3 | (Cu) |

H400 | ≤0.10 | ≤1.0 | 6.0-9.0 | 17.0-19.5 | ≤3.5 | ≤0.3 | - | |

Japan | YUS130S | 0.09 | 0.5 | 11.0 | 18.0 | 6.5 | 0.35 | - |

NTK S-4 | 0.17 | 0.43 | 14.7 | 17.7 | 1.3 | 0.35 | - | |

NM15M | 0.08 | 0.8 | 14.5 | 17.0 | 4.3 | 0.33 | - | |

Europe America | 219 | ≤0.04 | ≤0.75 | 8.0-10.0 | 19.0-21.5 | 5.5-7.5 | 0.15-0.4 | - |

Cromanite | ≤0.08 | ≤1.0 | 9.5-11.0 | 18.0-20.0 | ≤1.0 | 0.4-0.6 | - | |

201 Surface | Characteristic and Application of Stainless Steel Coil Cold Rolled 201 |

2B | The surface brightness and flatness of 2B is better than 2D then through a special surface treatment to improve its mechanical properties,2B could nearly Satisfy comprehensive uses |

No.4 | Polished with abrasive belt of grit#150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and electrical appliances kitchen utensils and food processing. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness like mirror kitchen apparatus, etc. |

8K | The product have excellent brightness and prefer bright can be the mirror. |

5. FAQ of Stainless Steel Coil Cold Rolled 201

Q: Are you factory or trader?

A: We certainly are stainless steel manufacturer and have processing plant.

Q: Can you provide mill test certificate?

A: Yes! Mill test certificate for both hot rolled raw material coils and cold rolled coils are available.

Q: Can you make DDQ (Deep drawing quality)?

A: Yes. Our material has been widely used for producing stainless steel pots and stainless steel sinks, which have strict request for good deep drawing quality.

Q: How to visit your factory?

A: Most of the main cities in the world have flight to Beijing; you can take flight to Beijing first, then we will lead you to our Wuxi mills.

Q: How about your company?

A world class manufacturer & supplier of castings forging in stainless steel, is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 90000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service are available, all according to customer’s requirements.

Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q: How is the packaging and delivery?

A: Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term is based on the project.

- Q: Are stainless steel strips suitable for automotive exhaust systems?

- Yes, stainless steel strips are suitable for automotive exhaust systems. Stainless steel is highly resistant to corrosion, heat, and extreme temperatures, making it an ideal material for exhaust systems that are exposed to these harsh conditions. It also provides excellent durability and longevity, ensuring the exhaust system can withstand the demands of automotive use.

- Q: Are stainless steel strips resistant to abrasion?

- Yes, stainless steel strips are highly resistant to abrasion.

- Q: What are the different types of surface defects in stainless steel strips?

- There are different types of surface defects that can occur in stainless steel strips, which can have an effect on their overall quality, appearance, and performance. Some commonly encountered surface defects in stainless steel strips are as follows: 1. Scratches: These are visible lines or grooves that can be seen on the surface of the strip. They can occur during the manufacturing process, handling, or transportation. Scratches can vary in depth and severity, and if they are deeper, they can potentially impact the corrosion resistance of the stainless steel. 2. Pits: Pitting refers to the formation of small cavities or depressions in localized areas of the strip's surface. Pits can be caused by different factors, such as exposure to corrosive environments, improper cleaning, or manufacturing defects. The presence of pits can compromise the integrity of the stainless steel and make it more susceptible to corrosion. 3. Stains: Stainless steel strips can develop stains or discoloration due to exposure to chemicals, heat, or improper cleaning methods. Stains can range from slight discoloration to more severe, deep stains that are difficult to remove. These defects can affect the appearance of the stainless steel and may also indicate a compromised protective oxide layer. 4. Roll marks: Roll marks are impressions or ridges that appear on the surface of the stainless steel strip during the rolling process. These marks can appear as lines or patterns and are usually caused by uneven pressure or improper alignment of the rolling equipment. Roll marks can impact the aesthetics of the stainless steel and may also affect its mechanical properties. 5. Weld defects: Stainless steel strips that are produced through welding processes can exhibit various types of weld defects, such as weld spatter, incomplete fusion, or excessive penetration. These defects can weaken the joint and reduce the overall strength and corrosion resistance of the stainless steel strip. 6. Surface contaminants: Surface defects in the form of contaminants, such as dirt, oil, grease, or foreign particles, can be present on stainless steel strips. These contaminants can be introduced during manufacturing, handling, or storage, and can have a negative impact on the performance and appearance of the stainless steel. It is important to note that the severity and impact of these surface defects can vary depending on the intended application of the stainless steel strip. Manufacturers implement various quality control measures to minimize these defects and ensure that the stainless steel strips meet the required standards.

- Q: Can stainless steel strips be used in the mining industry?

- Yes, stainless steel strips can be used in the mining industry. Stainless steel is a versatile and durable material that offers excellent resistance to corrosion, high temperatures, and mechanical stress. These properties make it suitable for various applications in the mining industry. Stainless steel strips can be used in mining equipment and machinery, such as conveyors, crushers, screens, and tanks. They are commonly used for lining chutes and hoppers, as well as for fabricating wear-resistant parts and components. Stainless steel strips can also be used in the construction of mining infrastructure, such as pipelines, storage tanks, and processing plants. The mining industry often operates in harsh environments, including exposure to corrosive chemicals, abrasive materials, and extreme temperatures. Stainless steel's resistance to corrosion and high-temperature performance make it an ideal choice for applications where other materials may deteriorate quickly. Furthermore, stainless steel is easy to clean and maintain, which is crucial in the mining industry where cleanliness is essential for optimizing operational efficiency, reducing downtime, and ensuring product quality. In summary, stainless steel strips can be effectively used in the mining industry due to their corrosion resistance, high-temperature performance, durability, and ease of maintenance. They provide a reliable and long-lasting solution for various applications in mining equipment, machinery, and infrastructure.

- Q: Can stainless steel strips be powder coated?

- Yes, stainless steel strips can be powder coated. Powder coating is a popular method of applying a protective and decorative finish to various materials, including steel. The process involves applying a dry powder to the surface of the stainless steel strips and then curing it in an oven. This results in a durable and uniform coating that adheres well to the metal surface. Powder coating offers several benefits, such as resistance to chipping, scratching, and fading, as well as enhanced durability and corrosion resistance. It also provides a wide range of color options and can be used to achieve different finishes, such as glossy, matte, or textured.

- Q: Are stainless steel strips resistant to atmospheric corrosion?

- Stainless steel strips possess resistance against atmospheric corrosion, indeed. The presence of chromium in stainless steel prompts the development of a protective layer upon exposure to oxygen. Termed as a passive film, this layer acts as a barrier, effectively impeding any subsequent corrosion. Moreover, stainless steel incorporates additional alloying elements like nickel and molybdenum, which augment its resistance against atmospheric corrosion even further. Consequently, stainless steel strips exhibit exceptional resistance against rust, tarnish, and other manifestations of atmospheric corrosion, rendering them an ideal selection for diverse applications exposed to outdoor environments.

- Q: What are the common uses of stainless steel strips in the pharmaceutical manufacturing process?

- Stainless steel strips play a crucial role in the pharmaceutical manufacturing process due to their unique properties and characteristics. Here are some common uses of stainless steel strips in pharmaceutical manufacturing: 1. Equipment fabrication: Stainless steel strips are extensively used for fabricating various pharmaceutical equipment such as mixing tanks, storage tanks, reactors, and piping systems. The corrosion resistance and hygienic properties of stainless steel make it ideal for maintaining a sterile environment and preventing contamination during the manufacturing process. 2. Pharmaceutical packaging: Stainless steel strips are commonly used for manufacturing pharmaceutical packaging materials such as vials, ampoules, and syringes. The high strength and durability of stainless steel strips ensure the protection and integrity of pharmaceutical products, especially those that are sensitive to external factors like moisture and temperature. 3. Cleanroom construction: Stainless steel strips are utilized in the construction of cleanrooms, which are critical for pharmaceutical manufacturing. These strips are used for creating partition walls, flooring, and ceilings, providing a sterile and controlled environment for the production of pharmaceutical products. 4. Conveyors and material handling systems: Stainless steel strips are employed in the construction of conveyors and material handling systems used in pharmaceutical manufacturing. These strips provide the necessary strength and resistance to chemicals and wear, ensuring the smooth and efficient movement of materials throughout the production process. 5. Filtration systems: Stainless steel strips are used in the fabrication of filtration systems, such as filter housings and filter cartridges. The anti-corrosive properties of stainless steel enable these filtration systems to effectively remove impurities, contaminants, and particles from pharmaceutical fluids and solutions. 6. Heat exchangers: Stainless steel strips are utilized in the construction of heat exchangers, which are vital for various pharmaceutical processes like sterilization, cooling, and heating. The excellent thermal conductivity of stainless steel enables efficient heat transfer, ensuring the precise control of temperature during the manufacturing process. Overall, stainless steel strips are indispensable in the pharmaceutical manufacturing process due to their corrosion resistance, durability, cleanliness, and ability to maintain a sterile environment. Their applications range from equipment fabrication to packaging, cleanroom construction, filtration, material handling, and heat exchange, playing a vital role in ensuring the quality and safety of pharmaceutical products.

- Q: What are the different packaging options for stainless steel strips?

- Stainless steel strips have various packaging options available to cater to the specific requirements and preferences of customers: 1. Coils: Coils are tightly wound stainless steel strips that are secured with straps or plastic wrap. They offer easy handling, transportation, and storage, making them efficient for large quantities. 2. Wooden Crates: For enhanced protection and durability, stainless steel strips can be packed neatly in wooden crates. Straps or foam inserts are used to secure the strips, preventing damage during shipping or storage. Wooden crates are commonly used for heavy-duty applications or long-term storage. 3. Pallets: Stainless steel strips can also be packaged on pallets, where they are stacked and secured with bands or shrink wrap. This option allows for convenient handling using forklifts and ensures stability during transportation. Pallets are suitable for smaller quantities of strips. 4. Bundles: Bundling stainless steel strips together using plastic or steel bands keeps them organized and secure, preventing tangling or damage. Bundles are ideal for smaller quantities, offering easy handling and storage. 5. Custom Packaging: Custom options for packaging stainless steel strips can be tailored to specific customer needs. This may involve adding protective covers, foam inserts, or custom labeling for easy identification. Custom packaging ensures adequate protection and readiness for use upon delivery. In conclusion, the packaging options for stainless steel strips vary depending on factors such as quantity, transportation requirements, and desired level of protection. Manufacturers and suppliers collaborate closely with customers to determine the most suitable packaging option, ensuring the safe and efficient delivery of stainless steel strips.

- Q: How are stainless steel strips different from stainless steel sheets or plates?

- Stainless steel strips, sheets, and plates are all forms of stainless steel, but they differ in terms of their dimensions and applications. Stainless steel strips are narrow and long pieces of stainless steel with a thickness usually ranging from 0.2mm to 6mm. They are commonly used in various industries such as automotive, construction, and manufacturing. Due to their thinness and flexibility, stainless steel strips are ideal for applications that require precise shaping, bending, or forming. They are commonly used in the production of components, springs, and electrical connectors. On the other hand, stainless steel sheets and plates are larger and thicker forms of stainless steel. Sheets typically have a thickness of 0.4mm to 6mm, while plates are thicker, ranging from 6mm to 80mm or more. Stainless steel sheets and plates are used in various sectors including architecture, kitchenware, and industrial equipment. Their larger size and thickness make them suitable for applications such as cladding, roofing, countertops, and heavy-duty machinery parts. While both stainless steel strips and sheets/plates are corrosion-resistant and durable, their different dimensions and applications make them suitable for specific uses. The choice between strips, sheets, or plates depends on the requirements of the project, including the desired thickness, size, and intended application.

- Q: What is the conductivity of stainless steel strips?

- Stainless steel strips have relatively low electrical conductivity compared to other metals due to their high resistance to electrical flow.

Send your message to us

Stainless Steel Coil Cold Rolled 201 Surface 2B with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords