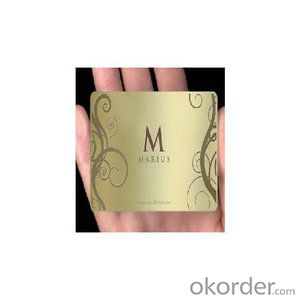

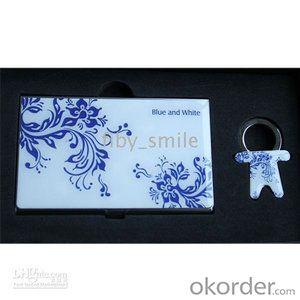

stainless steel business card holder oyster card holder

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Free custom design.

2.high quality

3.fast time

4.material:zinc alloy or cooper

5.craft: Die casting/struck

6.fast delivery time

♥ Description

1.Item:name card holder

2. Common Material:aluminium,iorn,stainless steel,zinc alloy

2.Common size: M:5cm x 7cm x2.5cm and L: 12.5*12*4.8cm or customized

4.process:stamping casting engraving etc

5.finish:embossed plating or printing

6.Plating:nickel,gold,silver,bronze

7.Epoxy:optional ,with or without

8.shape:rectangle

9.any custom design and size is available

10.OEM orders are highly welcome.

11.We make products in house, and can control the quanlity and production lead time very strictly

12.Picture shown here are for reference only, ASNY can help you based on any of your logo and specifics.

13. No sample charge, no artwork fee. No mold cost if order qty attains 5,000pcs.

14. For more details, please contact us with the following information:

♣DELIVERY

1.Sampling Time:If the item with mould(old item),we need 4-7 days to make new samples.If the item without mould(new item),we need 9-16 days to make new samples.

2.Mass Production:Usually we send sample to customers for final confirmation,then begin to produce mass production.After buyer confirmed the samples,regular delivery time is 9-16 days,exact time depends on the order quantity.

3.We are not responsible for any accidents,delays or other issues that caused by the shipping couriers.But we will try our best to assist the buyer and shipping couriers to ship the package(s) if there is any problem.

4.We have cooperative shipping partner,if necessary,you can ask us for the ship cost.

- Q: What are the allowable quantity differences in printed packaging materials?

- Large areas of the current general offset printing, letterpress printing and other printing methods, the size of the largest paper size, the entire area of more than a full sheet size, it is limited by mechanical equipment. Screen printing can be a large area of printing, screen printing products today can reach up to 3 meters x 4 meters, or even higher significantly.

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- As a screen printing material, semi automatic screen printing machine for printing or anti India, in particular circumstances, is usually anti India, India will.

- Q: Carton printing process and materials

- Art paper gravure composite carton process, when the production of large quantities, without film, and requires good printing effect, low cost, you can use this process. This process is to use paper gravure printing machine printing thin coated paper, and then the printed coated paper and ordinary slag paper board or cardboard composite as a whole, carton paper, and then mounted on the carton forming normal.The process is characterized by:(1) the cost of making cartons is low. The main reason for the cost reduction is that the white board is changed into low weight coated paper, which is combined with cheap carton paper to reduce material cost.(2) beautifully printed. The gravure printing effect of paper is very exquisite.(3) gravure printing process is more complicated, and the cost is high, it is not suitable for printing, often revised carton products.(4) the operation and control methods of the printing process, such as paper compounding and box making, should be carefully explored and continuously accumulated and reasonably implemented. Otherwise, the waste rate will be easily increased.

- Q: What are the materials used in screen printing?

- Divided into printed screen and printed material, screen according to different processes are divided into water-based and solvent based, printed material according to different substrate is divided into ink and ink

Send your message to us

stainless steel business card holder oyster card holder

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords