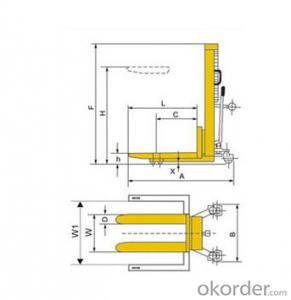

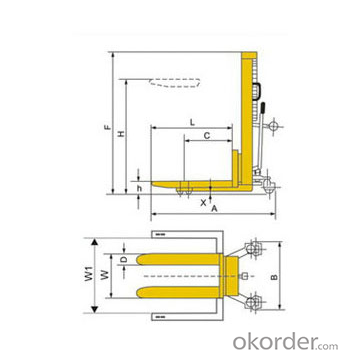

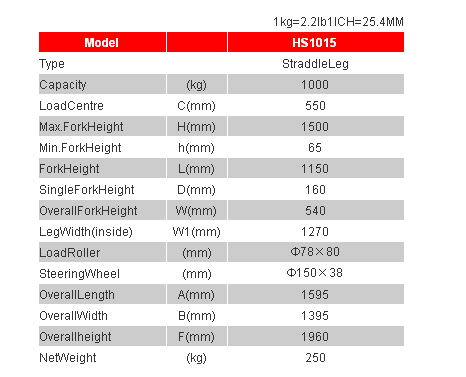

STACKER PRODUCT SERIE - Hand stacker-HS1015 HearvyDutyDesign

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Materialsandspecificationaresubjecttochangewithoutnotice.

HearvyDutyDesign

Uniquetechnologyofquickliftsystem

Compactdesignandstrong,accuratesteelconstruction

TopqualityhydraulicpumpandcylinderwithGermanseals.

Heavyduty1piece"C"sectionforksforgreateststrength.

Topofstrokebypassvalvebuiltin.

ConformstoEN1757-1:2001

All products are granted CE or GS certificates by Rheinland Group. The products are widely used in the field of modern logistic. There are seven product categories and over 2000 sorts. Besides standard products, we also customizes according to your requirements.

We focus on improving our core competitiveness and grasp the trend of upsizing, intelligentizing and environmental friendly. Based on self-developement and innovation, we cooperate with scientific research institution and schools and study new products, technique and craft which are suitable for market.

Stackers and reclaimers were originally manually controlled, with no means of remote control. Modern machines are typically semi-automatic or fully automated, with parameters remotely set. The control system used is typically a programmable logic controller, with a human-machine interface for display, connected to a central control system.

Other than stacking, a stacker has three basic movements:

Luffing: This is vertical movement. Stackers use either a winch mechanism with metal wire, or hydraulic cylinders, generally two. Winch mechanisms are highly reliable compared to hydraulic actuators and remain widely used, particularly in large stackers.

Travelling: The stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move around the stockyard as required. For this purpose, traction motors powered by direct current (DC) are connected by bevel gears to between 12 and 22 wheels. For manual control, all the controls are in a controller's cabin above the boom conveyor or boom. Modern stackers can be controlled remotely.

Slewing: This is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear. The axles may be multiple and are driven by DC-powered axle motors which transmit the torque via bevel or helical gears.

The conveyor belts used in stackers may be made of fabric or metal wire, depending upon the material to be handled. They are driven by pulleys, which in turn are driven by DC motors. The motors and gear are coupled by fluid coupling.

Most stackers are electrically powered by way of a trailing cable. There are basically two types of cable trailing: power cord rotating drum (PCRD) and control cable rotating drum (CCRD). Pendulum adjustments are made to ensure the proper alignment of these cables while the stacker is travelling.

- Q: Does the fixed hydraulic platform need to submit to the specification requirement

- Lift platform, mobile elevators, cargo-lifts equipment, such as the regulations of the state, load is larger than 500 kg of belong to special equipment, is the need in the local quality supervision of special equipment inspection. First, look at the equipment capacity is over 500 kg, then you should go to the local quality inspection of special equipment department to put on record, first need information: including manufacturer's business license, tax registration certificate, organization code certificate, production license of special equipment, special equipment installation and maintenance license, there are different from region to region, it's best to make a phone call to prepare the material.

- Q: There are several reasons for the hydraulic cylinder oil leak on the elevator

- Internal leakage 1) wear-resisting ring on the piston is badly worn, causing friction between the piston and the cylinder liner, and finally pulling the casing, piston and seal. Sealing long term failure, piston seal (mostly U, V, Y ring, etc.) aging; 3) the hydraulic oil is dirty, and a large amount of impurities enter the cylinder to seal the piston seal to the bad.

- Q: Is the elevator moving faster or slower?

- Speed of computing: lifting speed is equal to the lifting height/(the volume of a cylinder/pump displacement) this article provided by jinan international hydraulic machinery co., LTD. Is for reference only

- Q: What certificate is required to operate hydraulic platform

- Need special equipment to use the license, do this card is very expensive, seem to want 500 ~ 10000. Where did you buy it, because the house can do it for you? If the product does not meet technical review do not water,,,, I know there is a producers can do STH for sb, HuaNanJun industry machinery equipment co., LTD, special equipment to check more strictly, now,

- Q: Why is the large laser engraving machine plus half the platform?

- About whether to lift: all are generally two kinds of the lifting methods at present, screw support lifting and hydraulic elevator, screw because of the limitation of itself bearing part can only support plate lifting platform, so generally make some lifting; Hydraulic lift, JQ1325 hydraulic lift can be fully raised, the hydraulic platform can carry 4-10 tons of stone. More questions can be asked about the r&d department of jinan jinqiang laser digital control equipment co., LTD.

- Q: What is the hydraulic platform driven

- The engine or motor drive oil pump can also be used manually.I hope my answer will help you.

- Q: How to use the ball screw platform?

- A, before use, should read the instruction manual, elevator are pass strict inspection before they go out and debugging, the various technical indicators have reached the requirements of design, thus reading takes the manual carefully before using, strictly follow the steps.

- Q: How do you remove the horizontal universal elevator milling cutter

- Tie rod and the threaded part of the milling cutter is too short, removing cutter bar back a loose, threaded connections even fewer number of buttons, easily when tapping threads dozen hair, and make the cutter not screw down, or make the damage of tie rod.

- Q: Is the music console working? Want to start a, afraid to buy expensive again.

- And, it's easy to adjust, because the built-in gas spring, the girl can adjust the height easily. At the same time, 150 cm to 185 height is suitable.

- Q: The advantages and disadvantages of using diesel engine as an engine

- Polluted air, the exhaust fumes from diesel engines are not processed directly into the atmosphere, making environmental damage more serious. Make noise, noise pollution has become another environmental pollution, the diesel engine will obviously affect people's work and life when working. (3) at low temperature is not easy to start, when the environment temperature is lower than 5 ℃, the machine, diesel brand is undeserved, cause machine, diesel oil viscosity is bigger, the diesel engine crankshaft starting resistance moment is larger, it is difficult to start, affect the normal operation.

Send your message to us

STACKER PRODUCT SERIE - Hand stacker-HS1015 HearvyDutyDesign

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords