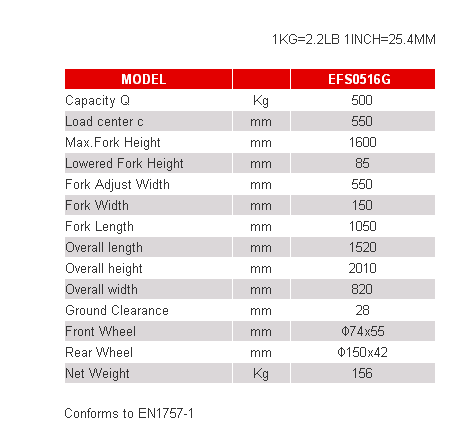

STACKER PRODUCT SERIE - Hand Stacker--EFS0516G

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

All products are granted CE or GS certificates by Rheinland Group. The products are widely used in the field of modern logistic. There are seven product categories and over 2000 sorts. Besides standard products, we also customizes according to your requirements.

We focus on improving our core competitiveness and grasp the trend of upsizing, intelligentizing and environmental friendly. Based on self-developement and innovation, we cooperate with scientific research institution and schools and study new products, technique and craft which are suitable for market.

Stackers and reclaimers were originally manually controlled, with no means of remote control. Modern machines are typically semi-automatic or fully automated, with parameters remotely set. The control system used is typically a programmable logic controller, with a human-machine interface for display, connected to a central control system.

Other than stacking, a stacker has three basic movements:

Luffing: This is vertical movement. Stackers use either a winch mechanism with metal wire, or hydraulic cylinders, generally two. Winch mechanisms are highly reliable compared to hydraulic actuators and remain widely used, particularly in large stackers.

Travelling: The stacker moves on a rail track, which may be broad or narrow gauge, enabling it to move around the stockyard as required. For this purpose, traction motors powered by direct current (DC) are connected by bevel gears to between 12 and 22 wheels. For manual control, all the controls are in a controller's cabin above the boom conveyor or boom. Modern stackers can be controlled remotely.

Slewing: This is rotation of the stacker around its central axis to align or place the stockpile where required. This works mostly by a slew pinion that rotates around a slew base. This type of gear assembly is called a sun and planet gear. The axles may be multiple and are driven by DC-powered axle motors which transmit the torque via bevel or helical gears.

The conveyor belts used in stackers may be made of fabric or metal wire, depending upon the material to be handled. They are driven by pulleys, which in turn are driven by DC motors. The motors and gear are coupled by fluid coupling.

Most stackers are electrically powered by way of a trailing cable. There are basically two types of cable trailing: power cord rotating drum (PCRD) and control cable rotating drum (CCRD). Pendulum adjustments are made to ensure the proper alignment of these cables while the stacker is travelling.

- Q: What is the phenomenon of the worker's transport of wood using a lift

- The elevator is divided into the following mobile, fixed, wall, tractive, self-propelled, vehicular, and retractable seven categories: mobile The shear fork lift platform is a special equipment for high-altitude operation. The mechanical structure of it, make the lifting platform lifting has high stability, wide operating platform and high bearing capacity, larger, and the area of aerial work for many people work at the same time. Lifting power is divided into 24 v, 220 v or 380 v power supply, diesel engine, with Italy and domestic hydraulic pump station, mesa use antiskid insulated gusset plate, with non-slip, insulation, safety, please be assured that use.

- Q: When the hydraulic platform drops, it feels very shaken and unbalanced. Please answer?

- Can you adjust the flow rate to slow down the same amount of pressure and the decrease is much faster than the increase. This does not know that the valve is connected to the solenoid valve, which may be the overflow valve or the balance valve The oil tank has no refueling mouth and oil outlet?

- Q: There are several reasons for the hydraulic cylinder oil leak on the elevator

- Internal leakage 1) wear-resisting ring on the piston is badly worn, causing friction between the piston and the cylinder liner, and finally pulling the casing, piston and seal. Sealing long term failure, piston seal (mostly U, V, Y ring, etc.) aging; 3) the hydraulic oil is dirty, and a large amount of impurities enter the cylinder to seal the piston seal to the bad.

- Q: The ball of the universal milling and lifting platform rolls off, how to install,

- Remove the screw and remove the poles, bearings, and bearings. Find a root (casing pipe diameter and the bottom of the screw thread diameter size, casing Canon and screw axis diameter size), the sleeves on the screw axis, the screw nut screw on the casing; When fully rotating to the casing, remove the casing and the screw nut. Slide to one end of the casing and the screw nut expose about half a circle ball nut (must pay attention to, don't put the ball, or ball will all fall out), with tiny rod or wire, adjust the position of the ball, with one or more of the position of the ball, then fill in falling ball (this step is very important, it is better to have a ball screw pair assembly experience to do); Once you have finished, put the casing on the shaft of the screw. Then turn the nut onto the screw.

- Q: To make a four trapezoid screw lifting up seven tons of lifting platform should be matched with the straight screw and motor

- Can be judged according to the accuracy requirement of lead screw grinding or rolling, depending on the load and its acceleration can choose servo power right away and screw the maximum load capacity (do longer engineers can intuitive judgment the diameter of the screw and large), so that you can around the power of the servo motor of the different speed and different lead screw to match, so there will be several different schemes: high speed servo motor with small lead screw (sometimes deceleration machine), big inertia servo with lead screw. Under the condition of the machine cost to determine, from two to three scheme choice, choice of method is to choose low cost, with high stability, cost effectiveness and cost are the same common and suppliers have a spot. If the single from choose the ways of the servo and screw usually have an intuition, like 3000 revolutions of servo goods on the market the most sufficient, screw is according to the supplier's inventory.

- Q: How to use the ball screw platform?

- A, before use, should read the instruction manual, elevator are pass strict inspection before they go out and debugging, the various technical indicators have reached the requirements of design, thus reading takes the manual carefully before using, strictly follow the steps.

- Q: How to use the elevator to be safer and more efficient

- Monthly check Roller, shaft and bearing, oil cylinder pin shaft and bearing, arm hinge shaft and bearing, etc. All parts should be filled with lubricating oil to extend the life of the bearing. Oil and oil level of hydraulic oil. The platform rises all the way up, and in this position, the hydraulic pressure should be 40 to 50 mm above the bottom of the box. The hydraulic oil is dark, sticky or gravel, etc. If found, it should be replaced in time (32 # hydraulic oil).

- Q: Safety operation of hydraulic platform

- Don't overload your operations; Try to be as special as possible; Try to troubleshoot the professionals if possible. In conclusion, the operation of strict accordance with the operating procedures provided by the manufacturer is the main body of the security guarantee

- Q: What is the difference between elevator and elevator platform and high-altitude platform

- The elevator will use the motor to reverse the deceleration and pull the cable to lift the basket. The platform, like the high-altitude operating platform, USES hydraulic oil to pressurize or unload the platform. High altitude (pinyin: gao kong zuo ye) refers to the work performed at a certain location on a high level. National standard GB 3608-2008 "high job grading" regulation: "where in the fall for more than 2 m height datum (2 m) to operate the heights of the likely to fall, are called high homework." According to this rule, the scope of the construction industry is quite extensive. When working in a building, operate on a shelf above 2m.

- Q: What is the imported hydraulic platform car? Kneel and beg your help

- Their platform has a special mechanical structure that is widely used in high-altitude work, the shear fork structure, and the higher stability after lifting and lifting

Send your message to us

STACKER PRODUCT SERIE - Hand Stacker--EFS0516G

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords