ST EP NN Heat resistan rubber conveyor t belt

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

classification

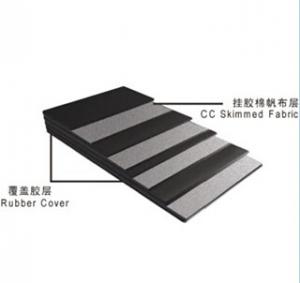

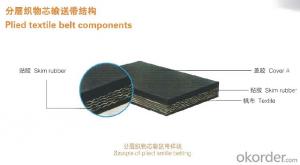

Heat-resistant conveyor belt is divided into ordinary heat-resistant belt and strong heat-resistant conveyor belt, ordinary heat-resistant layer for the polyester-cotton canvas (CC56), strong heat-resistant layer for the EP (specifically divided into EP100, EP150, EP200, EP250, EP300, EP350, EP400, EP450, EP500, etc.).

use

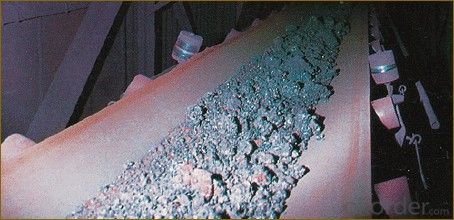

Mainly used in metallurgy, construction and other industries, conveying sintered ore, coke, cement clinker and other high-temperature materials, material temperature does not exceed 800 ℃, with a surface temperature of not more than 220 ℃ under the conditions of use. Features: EPDM rubber for the cover, frame materials used in domestic high temperature resistant canvas, a unique formula designed to solve the high degree of ethylene-propylene rubber saturation, poor adhesion, adhesion between the layers of low key issues . With a light body, long life (about 2-4 times), good heat resistance characteristics.

Implementation of the "conveyor belt with rubber or plastic cover the general purpose of the fabric core conveyor belt" standard, this standard adopts the international standard draft ISO / FDIS14890-1999 standard

Heat-resistant conveyor belt is made of multi-layer rubber cotton canvas (polyester-cotton cloth) or polyester canvas covered with high temperature or heat-resistant rubber, high temperature vulcanization bonding together, suitable for conveying 175 ℃ hot coke, cement, slag And hot castings.

1, the specifications with the ordinary conveyor belt.

2, the product implementation of HG2297-92 standard.

3, heat-resistant conveyor belt can be divided into four models:

Ⅰ type: can withstand not more than 100 ℃ test temperature, the maximum short-term operating temperature of 150 ℃, code T1.

Ⅱ type: can withstand not more than 125 ℃ test temperature, the maximum short-term operating temperature 170 ℃, code T2.

Ⅲ type: can withstand no more than 150 ℃ test temperature, the maximum short-term operating temperature of 200 ℃, code T3.

Ⅳ type: can withstand not more than 175 ℃ test temperature, the maximum short-term operating temperature of 250 ℃, code T4.

Physical properties

The difference between strength after aging and before aging (IRHD) 23

The maximum after aging (IRHD) 88

Tensile strength Property change rate reduced,% 40

After the minimum value of aging, MPa 5

Change in elongation at break,% 60

The lowest value after aging,% 150

High temperature steel wire conveyor belt is made of steel vertical and horizontal, steel mesh surface galvanized or copper, steel mesh in the upper and lower surface covered with rubber layer, the transport of high temperature materials, the overall surface does not delamination, the use of performance than hierarchical Heat-resistant conveyor belt more reliable.

Precautions for use

With the conveyor belt in the popularization of industrial production, multi-species, high-performance, lightweight, multi-functional, long life is the manufacturer of several aspects of concern. In industrial production, the proper use of conveyor belt is particularly important, conveyor belt in use should pay attention to the following:

1. To avoid roller covered by the material, resulting in rotation is not working to prevent leakage of material between the roller and tape in the tape, pay attention to the active part of the conveyor belt lubrication, but not oil conveyor belt;

2. To prevent the conveyor belt load start;

3. Conveyor belt deviation occurs, should take timely measures to correct;

4. When the conveyor belt is found to be damaged, the artificial cotton should be repaired in time so as not to expand.

5. To avoid the conveyor belt by the rack, pillar or block material block, to prevent break-breaking rip.

Key Features

This type of conveyor belt is mainly used for metallurgical, building materials, casting, coking, chemical and other industries conveying sintered ore, coke, cement, fertilizer and other high-temperature solid materials, with the required heat resistance. Heat-resistant conveyor belt heat resistance and service life depends on the cover layer and core with the heat resistance. Generally good heat resistance of rubber such as: styrene butadiene rubber, butyl rubber, ethylene propylene rubber as the main compound to heat, heat shrink small polyester-cotton, polyester-Jin canvas with a core. Heat-resistant conveyor belt according to the test temperature is divided into four grades. T1: Test temperature at which heat resistance is not more than 100C; T2: Test temperature at which heat resistance is not more than 125C; T3: Test temperature at which the heat resistance is not greater than 150C; T4: Test for heat resistance not exceeding 175C temperature. Heat-resistant conveyor belt strength specifications and width of the same specifications and ordinary conveyor belt. Example of tape marking: 200 1200 EP 5 1000 8 + 3 T2 This tape has a length of 200 m and a width of 1200 mm. The tape has five layers of EP canvas, the strength specification is 1000N / mm, the upper and lower cover layers are 8mm and 3mm respectively, Can be resistant to heat is not greater than 125 ℃ test temperature. The implementation of such products GB / T 20021-2005 "canvas heat-resistant conveyor belt," the national standard. In order to meet the higher use of temperature, some manufacturers have also developed the ability to withstand higher temperature levels of heat-resistant conveyor belt and the burning of high-temperature conveyor belt, usually in the overlay compound added flame retardant insulation, anti-burning Etching agent, heat agent, etc., in order to improve the high-temperature anti-erosion properties of tape.

Product Features

Heat-resistant conveyor belt is made of multi-layer rubber cotton canvas (polyester-cotton cloth) covered with high temperature or heat-resistant rubber, high temperature vulcanization together, suitable for conveying below 240 ℃ hot coke, cement, slag and hot castings . 1, the specifications with the ordinary conveyor belt. 2, the product implementation of HG2297-92 and GB / T20021-2005 standards. 3, heat-resistant conveyor belt can be divided into five models: Ⅰ type: can withstand not more than 100 ℃ test temperature, the maximum short-term operating temperature of 150 ℃, code T1. Ⅱ type: can withstand not more than 125 ℃ test temperature, the maximum short-term operating temperature 170 ℃, code T2. Ⅲ type: can withstand no more than 150 ℃ test temperature, the maximum short-term operating temperature of 200 ℃, code T3. Ⅳ type: can withstand no more than 175 ℃ test temperature, the maximum short-term operating temperature of 400 ℃, code T4. Ⅴ type: can withstand no more than 240 ℃ test temperature, the maximum short-term operating temperature of 600 ℃, code T5.

Market: Cement, Foundry, Iron Ore, Steel Production.

Applications: Cement Clinker, Coke Plants, Hot Power Materials, Sintered Ore, Steel Mills, Taconite Pellets.

Tensile strength: 500~8000N/mm Width :500~3200mm

Features & Benefits:

1》、Heat-resistant cover resists cracking and hardening

heat-resistant belt performs over the long run, retaining its flexibility despite punishing condition and loads. Less cracking and hardening translates into longer life and reduced replacement costs. Heat-resistant belt compound retains its Heat-resistant qualities after prolonged exposure to 200℃ hot loads.

2》、High-temperature resistance to tearing and abrasion.

Load after load, huayue belt stands up to prolonged exposure. This reduced maintenance and downtime helps lower overall operating costs.

3》、High strength carcass construction

the carcass use steel wire or synthetic material. Synthetic carcass provides great dimensional stability and strength at high temperatures and operating tensions up to 2000 kN/mm.

4》、The carcass with heat-resistant material

the apply special carcass in the heat-resistant belt, provide maximum protection when temperatures are not constant. The carcass stand up to “hot shots”, resisting burn-through up to 538℃.

- Q: Conveyor rubber belt welding

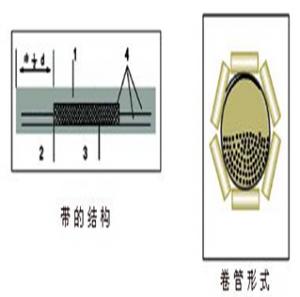

- The conveyer belt is composed of reinforcing material (core), core material (adhesive), covering rubber and adhesive.(1) reinforced material (belt core): it is the key of conveyor belt bearing, it determines the tensile strength of conveyor belt, and can absorb the impact of material on conveyor belt.(2) core material (adhesive): it has good adhesive strength between the reinforcing material and fabric layer, and prevents the lamination of the core during use.(3) covering rubber: it has the functions of protecting and reinforcing material, transmitting power, conveying material, absorbing material and resisting abrasion.(4) side rubber: protect the reinforced material from erosion by medium, absorb the extrusion force from the side of conveyer belt, prevent the lamination of core.

- Q: What sectors does rubber drive? That is to say, what are the main uses of rubber?

- Cars, railways, shoes, wires, cables, new materials, many

- Q: What kind of rubber belts are there for sporting goods?

- When the elastic band is stretched, the resistance starts from zero, while the traditional dumbbell barbell resistance is constant and is always affected by the direction of gravity. The ratio of stretched stretch of the elastic band is proportional to the elongation ratio of the muscle, which makes the muscle strength training more efficient. At the same time, the direction of the resistance will not be affected by gravity.

- Q: How many layers of rubber band are glued together?

- Niron (NN) and polyester (EP) conveyor belts:The average adhesive strength between the layers is not less than 4.5N/mm, and the ratio between the coating and the cloth is not less than 3.2 N/mmFull thickness longitudinal elongation of not less than 10%, the thickness of longitudinal reference force elongation is not greater than 4%

- Q: How should the rubber strap be cleaned and maintained?

- At present, rubber band is very popular, and silicone rubber material non-toxic, high and low temperature, acid and alkali resistance, flexibility, easy maintenance, waterproof good. As a watch band, it can be considered as the best material. The only disadvantage is that it needs to be replaced promptly after aging. Therefore, a good maintenance can increase the life of the strap.

- Q: White rubber strap dirty, how to do?

- Then wash the back of the strap and clean the surface first. Next, clean the stains in the gap.Finally clean the strap with clean water. The procedures are completed, the rest of the things is to put the watchband in shady place to dry, do not pay attention to sun, will damage the quality of watchband.

- Q: What is the role of the rubber band Caoguan vehicle above

- Electrostatic guided rubber traction belt is mainly used for transporting dangerous chemicals in tanks, tanks, cars, tanks, car shelves, electric static rubber and towing belts. It can prevent fire accidents caused by static electricity

- Q: What do you call a machine that folds rubber bands into a stamp?

- The word "mechanical" in modern Chinese is the generic term for "Mechanism" and "machine" (Machine). Mechanical features are: machinery is a combination of artificial physical components. A definite relative motion between the parts of a machine. So the machine can convert mechanical energy or perform useful mechanical power, is the modern mechanical principle in the basic concept, the modern concept of multi-source Chinese mechanical word from the Japanese "machinery", Japan's machinery products do the following definition of mechanical concept (that is consistent with the following three features called Machine).

- Q: What is the function of the coal feeder? What are the common types of coal feeder?

- Bring a coal machine powered by motor cycloid reducer, zmjt030 has the advantages of compact structure, stable operation, wide speed range and can realize stepless speed regulation; the annular rubber belt, rubber ring belt tensioning device to modified tension wheel the regulation can adjust the tightness of the belt and running due to the skewness, ring mechanism to achieve continuous coal and coal to one-way reciprocating to the machine, and greatly improve the work efficiency and the use of the chain of cast 16Mn alloy as the working surface to improve the service life of the equipment and the nylon rod pin connecting the structure have a strong impact resistance. The feeding range is large (0 ~ 500mm). This equipment is widely used in coal feeding at the end of raw coal. Because of its high production efficiency and stable working performance, it has a high market share.

- Q: The rubber strap is a little tight, is it better or a little loose?

- The watch is no longer a ticking tool today. Your wrist is very thin, so I'll tell you what I know about trying to stretch on the elastic.

Send your message to us

ST EP NN Heat resistan rubber conveyor t belt

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords