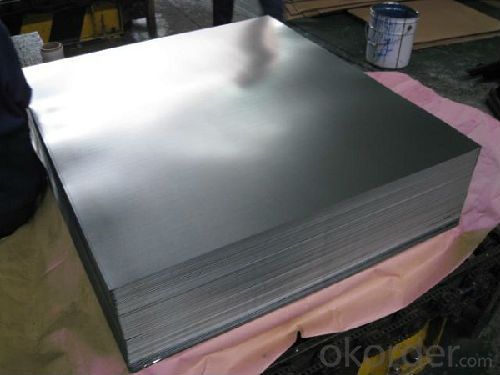

Prime Tinplate coil& sheet For Aerosol Can

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Quality Tinplate Sheets & Coils Details:

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

| | | | | | |

| | | | | |

Product Description:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

CNBM Introduction

China National Building Materials Group Cooperation, as a leading state-owned enterprise with 3 billion USD and 40,000 staff in China, CNBM was established in 1984 under the administration of the state-owned Assets Supervision and Administration commission of the State Council. There are over 300 surbordinate factories and companies in our group; 2 public listed companies in Hong Kong, 4 Public listed companies in China mainland; 11 publicly listed companies in which CNBM has a substantial percentage of shares. The business scope of CNBM covers from Manufacturing and sales of building materials to scientific research and design, engineering, import and export trading.

On July 7th, 2011, Fortune Magazine established Fortune Global 500 ranking on its website, and CNBM Group was listed for the first time, with a ranking of 485.

CNBM International Corporation

CNBM International Corporation, as an important import and export platform of CNBM Group, enjoys competitive advantages in importing and exporting of building materials as well as complete sets of machinery and equipments, engineering, and project contracting.

CNBM Branch Offices

In order to promote the business connection, CNBM has established branches and offices in lots of foreign countries, such as USA, GERMANY, UAE, SAUDI ARABIA, IRAN, JORDAN, LIBIA,ETHIOPIA, INDONESA, INDIA,VIETNAM,RUSSIA,KAZAKHSTAN. It is very helpful for the communication and after- sale services.

Factory Introduction

CNBM as one of the largest suppliers in tinplate industry, offers clientss prime quality tinplate in both coil and sheets. With multi-plants and fully integraded production, the annual capacity of tinplate is 400,000MT.

To ensure the high quality if the tinplate, CNBM owns complete equipment series.

- Reversing cold rolling machines: 14 sets

- Continuous rolling machines: 2 sets

- BA furnaces: 50

- CA line: 1

- Tinplate production line: 2

- SA& DA reduced tinplate sheet: Available

CNBM also produce other steel products, such as cold-rolled steel, hot dip galvanized steel, color coated steel and tin free steel coils and sheets.

- Q: What are the challenges in manufacturing tinplate?

- Some of the challenges in manufacturing tinplate include ensuring the uniformity of tin coating on the steel base, preventing corrosion during storage and transportation, maintaining the dimensional accuracy of the tinplate sheets, and addressing environmental concerns related to the disposal of tin and tin-containing wastewater. Additionally, meeting the specific quality requirements of different industries and managing the cost of production can also be challenging in tinplate manufacturing.

- Q: What are the benefits of using tinplate for pharmaceuticals?

- Tinplate offers several benefits for pharmaceuticals, including its excellent barrier properties that protect the medication from moisture, oxygen, and light. It is also resistant to corrosion, ensuring the integrity of the product throughout its shelf life. Moreover, tinplate is easy to sterilize, making it an ideal material for packaging drugs. Additionally, tinplate is sustainable, as it is 100% recyclable, reducing the environmental impact of pharmaceutical packaging.

- Q: Who knows the process of tinplate production?

- Cold rolling: the hot rolled strip passes through the pickling process and enters the cold rolling process. The strip is plastically deformed during the work roll, and the thickness is about 2mm.2mm from about 0. In cold rolling, in order to reduce the friction between the strip and the work roll and take away a large amount of heat produced by the plastic deformation, the cold rolling lubricant and coolant should be sprayed onto the strip. A reversible mill with single stand is adopted. In order to keep the shape of the roller effectively, the temperature control of the cooling liquid is more important. Range of production: 0.14mm-0.5mm.Slitting: the required width of slitting material after cold rolling. Range of production: 265mm-835mmSkim: in the cold rolling process in rolling oil cooling after tin plate surface adhesion of oil and other foreign matter, such as do not wash directly by annealing the oil incomplete combustion of carbonaceous residue will stain in the strip, for the production of tinplate can meet the quality requirements. Therefore, the tin plate must be cleaned by electrolysis before removing the grease. The common method of cleaning tin plate is to degrease and degrease the degreasing liquid.

- Q: How is tinplate different from aluminum packaging?

- Tinplate and aluminum packaging differ in terms of material composition, appearance, and properties. Tinplate is primarily made of steel with a thin layer of tin coating, while aluminum packaging is entirely made of aluminum. Tinplate has a characteristic silver color, whereas aluminum packaging has a metallic silver appearance. In terms of properties, tinplate offers excellent corrosion resistance and is commonly used for food cans, while aluminum packaging provides superior lightness, flexibility, and recyclability, making it suitable for various products like beverages, pharmaceuticals, and cosmetics.

- Q: How does tinplate packaging contribute to product portion control?

- Tinplate packaging contributes to product portion control by providing a pre-determined size and shape for the product. The rigid structure of tinplate containers ensures that a specific quantity of the product is packaged, enabling consumers to easily manage their portions and avoid overconsumption.

- Q: Can tinplate be used for packaging medical devices?

- Yes, tinplate can be used for packaging medical devices. Tinplate is a high-quality packaging material that offers excellent protection against moisture, light, and corrosion. It is widely used in the medical industry due to its durability, sterility, and ability to maintain the integrity of sensitive medical devices. Additionally, tinplate can be easily sterilized, making it suitable for packaging various medical equipment and devices.

- Q: Soup with tin cans loaded also need high temperature sterilization?

- Recently, the new provisions of the food industry has been introduced, did not look carefully, it seems that there is no preservative food should be high temperature sterilization.From the point of view of food safety, sterilization is also beneficial. You know that.

- Q: Tinplate which applies to product packaging?

- Tinplate has obvious superiority compared with other packaging materials.1. good mechanical properties: tinplate cans relative to other containers, such as plastic, glass, paper containers and uniform strength and good rigidity, it is not easy to break. It is not only used for small sale packing, but also the main container for large transportation package.

- Q: How does tinplate contribute to the efficiency of energy systems?

- Tinplate contributes to the efficiency of energy systems by providing a durable and lightweight material that can be used in various components such as cans, containers, and packaging. It helps in preserving and protecting energy resources, reducing energy consumption during transportation, and improving overall energy efficiency in the storage and distribution of goods. Additionally, tinplate is recyclable, which further supports sustainable energy practices and reduces waste in the energy system.

- Q: How does tinplate affect the cost of packaging?

- Tinplate can affect the cost of packaging by increasing it due to the higher price of tin compared to other materials. However, it also offers several advantages such as durability, extended shelf life, and enhanced product protection, which can justify the higher cost for certain applications.

Send your message to us

Prime Tinplate coil& sheet For Aerosol Can

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords