SP Concrete Prefab Slab making Machine for Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SP Concrete Prefab Slab making Machine for Roof

1. Structure of SP Concrete Prefab Slab making Machine for Roof:

Products of this series (non-circular and circular cored) are the ideal machines for making building materials on constructions of large span and heavy load bearing in factories, schools, hospitals, shopping centers, office building and homes.

Our hollow core slab machines have the advantages of reasonable design, easy operation, convenient maintenance and long working life. Slab length can be achieved to 4.2m to 18m; width of 600mm, 900mm and 1200mm; thickness of 120mm, 150mm, 180mm, 200mm, 250mm, 300mm, 380mm.

The hollow core slab machines are working on the long-line table, tensioning the high-strength and low-relaxation steel strand first, and using the pushing work method to form the concrete hollow core slab. The slabs which being formed have the advantages of smooth surface and high-density structure.

2. Main Features of SP Concrete Prefab Slab making Machine for Roof:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

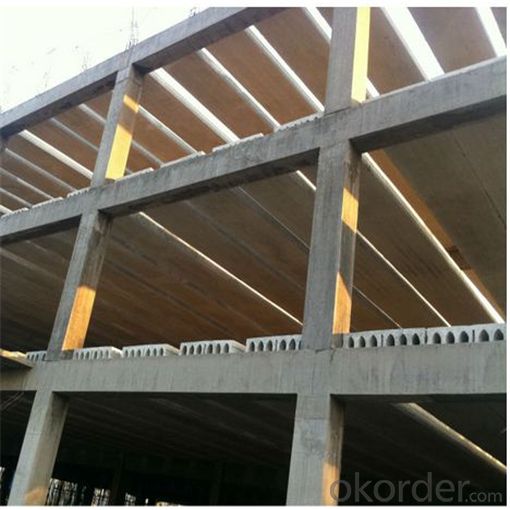

3. SP Concrete Prefab Slab making Machine for Roof Images:

4. SP Concrete Prefab Slab making Machine for Roof Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: Bq: have you read elfen liedBq2: favorite quote from a book

- Kyrie- Mr. Mister Bq: No. Bq2: And in its sky was such a sun as no opium eater could have imagined in his wildest dreams. Too hot to be white, it was a searing ghost at the frontiers of the ultraviolet. (Childhood's End-Arthur C. Clarke-Chapter 16-The Last Generation)

- Q: i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- Motion is produced by some of the following: 1) rotating magnetic fields (electric motors) 2) explosions (internal combustion engine) 3) heat expansion of gas (steam engine, rockets) I am not sure about friction in outer space but I believe because there is no air or gases around joints and gears, friction would literally vacuum cement the sliding parts together. You would need to ensure that some sort of matter (gas, liquid) was present in order to allow parts to slide on top of each other.

- Q: Mechanical equipment (automation equipment) What is the composition of the material, is steel or iron or other?

- Do not know whether to use machining or forging, casting can process such complex parts and high precision, so I would like to ask where this technology is high, where the plant or the company more.

- Q: What was the last thing that prevented you from driving or operating heavy machinery?

- Well, for one, the fact that I don't have a driver's license, and for two, the po-po impounded my steamroller.

- Q: what are the machinery in which threads are used for power transmission?

- Ball screws and ACME screws are often used as the means to provide thrust in a linear actuator. Linear actuators are present in many, many applications.

- Q: Any web site could get free machinery manual?

- actually, okorder /... Cheers nb: please visit my web site

- Q: I know the basics - clear cut the trees, put explosives in the mountains, blow the mountain up, separate coal from waste, fill up valleys and then plant some grass. What I want to know if more about the machinery used - some sites talk about a quot;dragline,quot; but don't have any more info than quot;it is used in MTRquot; What kind of explosives are used? How do they gather/separate the coal from the mining waste?

- well my company uses m-80's and m-90's so yeah. i always light a roman candle for safety issues

- Q: what does machinery safety engineer do?

- Just a wild guess... works on the safety aspects of machinery??

- Q: Or do I have to claim my business as a medium size cooperation?

- No, but many employers wait till the day before payday to report them, or so I heard. Two free weeks of work and the old, Gee, I didn't realize...

- Q: Libraries in Chicago withcollections of trade catalogs. Chicago Machinery Exchange 1900-30?

- The Newberry Library (it's in the Gold coast) has many old items. They are very knowledgeable about this type of thing, they might know where to find it if they don't have it.

Send your message to us

SP Concrete Prefab Slab making Machine for Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords