Prefab House Concrete Hollow Core Roof Slab Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prefab House Concrete Hollow Core Roof Slab Making Machine

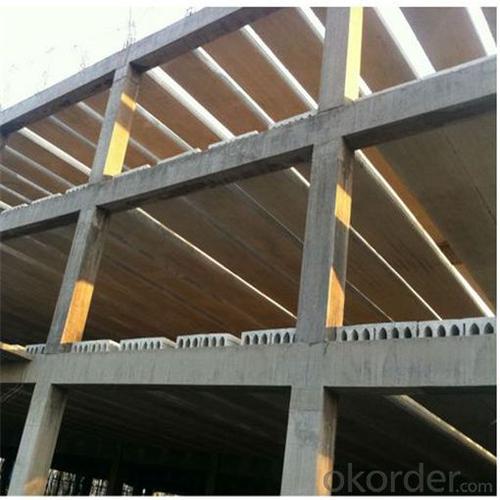

1. Prefab House Concrete Hollow Core Roof Slab Making Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Prefab House Concrete Hollow Core Roof Slab Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Simple structure, easy operate, less wear parts

3. Prefab House Concrete Hollow Core Roof Slab Making Machine Images:

4. Prefab House Concrete Hollow Core Roof Slab Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: How to choose mechanical parts material ah?

- You can refer to other people to design similar products, assembly map material selection, individual you need special requirements of their own design.

- Q: I am tired of politics and politicians and tired of liars with silky tongues merely seeking power and not in the best interests of the people.

- Dude. Have you ever studied history and read what Washington, Adams, Hamilton and the majority of the founding fathers really thought of the average, common working man. It wasn't pleasant, and it hasn't changed.

- Q: if not how much would you pay for one if i did it (NOT)

- There okorder /... may be an example

- Q: I am making a hypothetical business for school and have decided to create a business that makes whey protein powder from the whey left over from the making cheese. I have searched all over the net but I cant find any information on the machinery used in this process. Can anyone help

- nope

- Q: I hate working out in public gyms and exorcise rooms if other people are there for some reason. And I hate running in public (I've ran at night before, but now I don't have any time with so much schoolwork). I was wondering what some good exorcises i can do at home every day that don't take long but will make a difference. I was hoping to work my stomach muscles more so i can get in shape for swimsuit season. Thanks! (:

- brisk okorder

- Q: how can i acquire barrel assembly machinery for coffee bean processing?

- The okorder /

- Q: Hey, so I'm currently working on business coursework. We need to create a made up a business and i have chosen one of those businesses that print peoples picture on to items such a t-shirts, coasters mugs etc.. On one section i need to talk about the equipment and machinery i will need and to be honest i have no idea! could anybody give me a list of them?

- Well, it is possible you have chosen one of the most difficult businesses to theorize. Printing on t shirts can be done digitally, or using silk screens, or myriad other ways all of which have their benefits and drawbacks. Doing digital printing requires a machine that looks pretty much like a giant inkjet printer where the design is printed much like printing on paper with a few other details. I could go on and on but the homework is yours...

- Q: machinery purchsed entry and derpeciation charged for it?

- The purchase: Dr. Machinery (Fixed Assets) Cr. Cash / Accounts Payable Depreciation: Dr. Machinery Depreciation Expense Cr. Machinery Accumulated Depreciation Note that the accumulated depreciation is a contra account for the fixed assets, and what appears on the Balance sheet is the net of the two figures.

- Q: i want to buy from china

- through the service you just like engage a agent in China to help you to find what you need in China.

- Q: Libraries in Chicago withcollections of trade catalogs. Chicago Machinery Exchange 1900-30?

- The Newberry Library (it's in the Gold coast) has many old items. They are very knowledgeable about this type of thing, they might know where to find it if they don't have it.

Send your message to us

Prefab House Concrete Hollow Core Roof Slab Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords