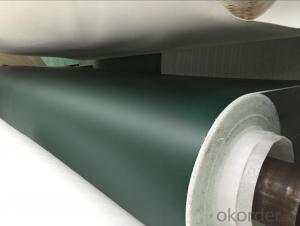

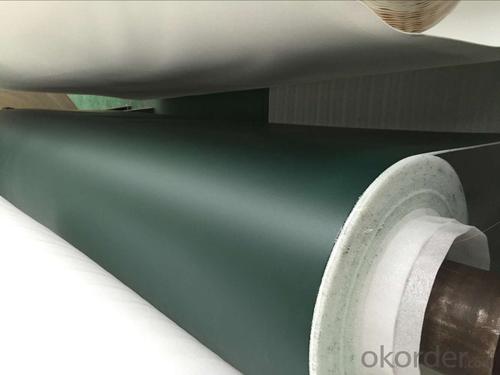

Smooth Gloss/Matt PVC/PU Conveyor Belt For Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Smooth Gloss/Matt PVC/PU Conveyor Belt For Food Industry

PVC/PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Polyvinyl chloride, commonly abbreviated to PVC, is the third most widely produced plastic after polyethylene and polypropylene. Polyvinyl chloride is produced by polymerization of the monomer vinyl chloride.

PVC is widely used in construction because it is durable and easily worked. It can be made softer and more flexible by the addition of plasticizers. In this form, it is used in clothing and upholstery, electrical cable insulation, inflatable products, and many applications in which it replaces rubber.

PVC's biological and chemical resistance and workability have resulted in its use in a wide variety of applications. It is used for sewerage pipes and other pipe applications where cost or vulnerability to corrosion limits the use of metal. With the addition of impact modifiers and stabilizers, it has become a popular material for window- and door frames. By adding plasticizers, it can become flexible enough to be used in cabling applications as a wire insulator.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

Please contact us freely if you need any conveyor belt.

- Q: Are there any specific guidelines for using olive nets on young or newly planted olive trees?

- Yes, there are specific guidelines for using olive nets on young or newly planted olive trees. It is generally recommended to avoid using nets on young trees, especially during the first year of growth, as they need maximum sunlight exposure for healthy development. However, if nets are required for protection against birds or pests, it is advised to use them only during fruiting season and ensure they are loosely draped over the trees to allow sufficient air circulation and prevent damage to the delicate branches. Regular monitoring and adjustments may also be necessary to avoid any potential harm to the young olive trees.

- Q: Do olive nets require any specialized equipment for installation?

- Yes, olive nets do require specialized equipment for installation. Typically, they need poles, support structures, and anchoring systems to secure the nets properly and ensure effective coverage over the olive trees.

- Q: Can olive nets be used in combination with tree spacing techniques?

- Yes, olive nets can be used in combination with tree spacing techniques. Olive nets are commonly used to protect olive trees from bird damage and to collect fallen olives during harvesting. By utilizing tree spacing techniques, such as planting trees at specific distances apart, it is possible to optimize the use of olive nets and ensure effective coverage and protection for the entire olive orchard.

- Q: What are the different types of olive nets available?

- There are several types of olive nets available, including standard square mesh nets, diamond mesh nets, and knitted nets. Each type has its own unique features and benefits, such as varying mesh sizes, durability, and ease of use. It is important to choose the right type of olive net based on your specific needs and the conditions of your olive grove.

- Q: Do olive nets affect the growth of olive trees?

- Yes, olive nets can affect the growth of olive trees. These nets are commonly used to protect olives from birds and other pests, but they can also impact the tree's growth by reducing sunlight penetration and air circulation. This can potentially result in reduced photosynthesis, nutrient uptake, and overall growth of the olive tree. However, if the nets are properly managed and allow for sufficient light and air flow, their impact on tree growth can be minimized.

- Q: Can olive nets be used in different types of olive orchards?

- Yes, olive nets can be used in different types of olive orchards. Olive nets are designed to protect the olives from birds, insects, and other pests, and can be used in various orchard setups including traditional groves, high-density plantations, or even in pots for small-scale cultivation. The nets are versatile and can adapt to different orchard structures and sizes to ensure the safety and quality of the olives during the growing season.

- Q: How are olive nets cleaned after use?

- Olive nets are typically cleaned after use by removing any debris or excess olive residue from the netting. This can be done by shaking or brushing off the loose materials. Afterwards, the nets can be washed with water and mild detergent to remove any remaining dirt or stains. Once cleaned, the nets should be thoroughly dried before storing or reusing them.

- Q: How does an olive net affect the overall fruit quality in the olive grove?

- An olive net can positively affect the overall fruit quality in an olive grove. It helps to protect the olives from external factors such as birds, insects, and wind, reducing the risk of damage or contamination. By preventing these factors from coming into contact with the olives, the net helps maintain their integrity and quality. Additionally, the net can also provide shade, which can regulate the temperature and prevent excessive sun exposure, thus contributing to better fruit quality.

- Q: How do olive nets prevent olives from falling on the ground?

- Olive nets are designed to be spread over the trees, creating a barrier between the olives and the ground. The nets catch the olives as they naturally fall from the branches, preventing them from hitting the ground and potentially getting damaged or contaminated.

- Q: Can olive nets be used in combination with pruning nets?

- Yes, olive nets can be used in combination with pruning nets. Olive nets are typically used to catch the falling olives during harvest, while pruning nets are used to catch the branches and debris during the pruning process. By using both nets together, it ensures a more efficient and organized harvest and pruning operation.

Send your message to us

Smooth Gloss/Matt PVC/PU Conveyor Belt For Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords